Smoke pre-desulfuration system

A pre-desulfurization and flue gas technology, applied in the field of flue gas purification, can solve the problems of large changes, large gaps, and large sulfur content, and achieve the effect of low installation cost, small changes, and improved desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

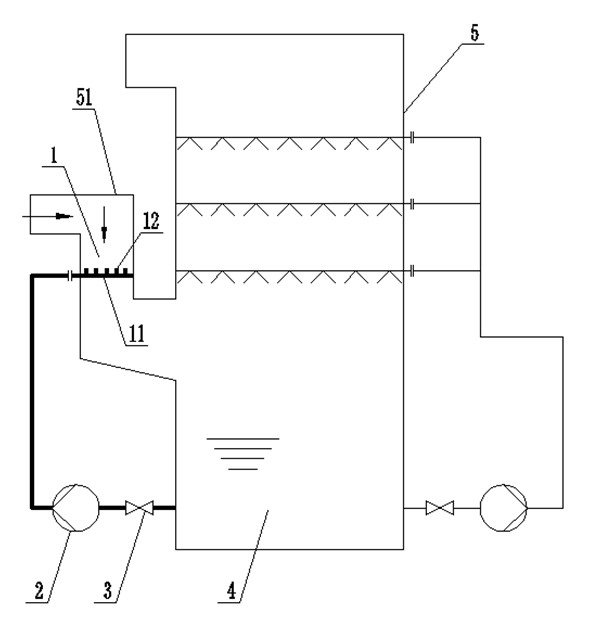

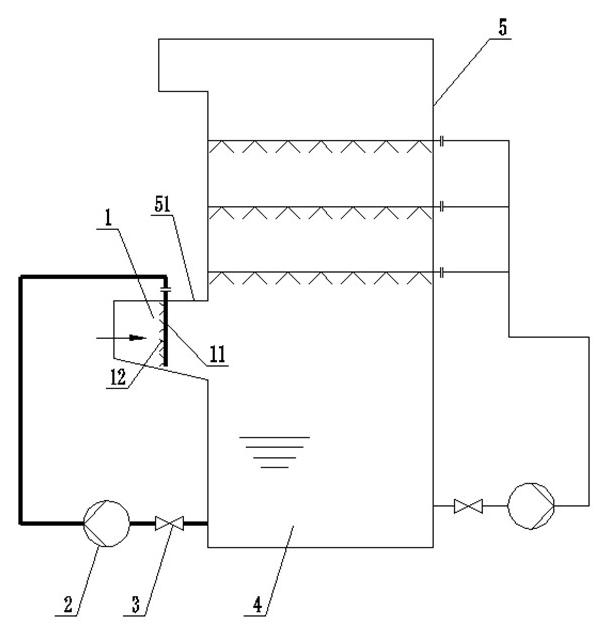

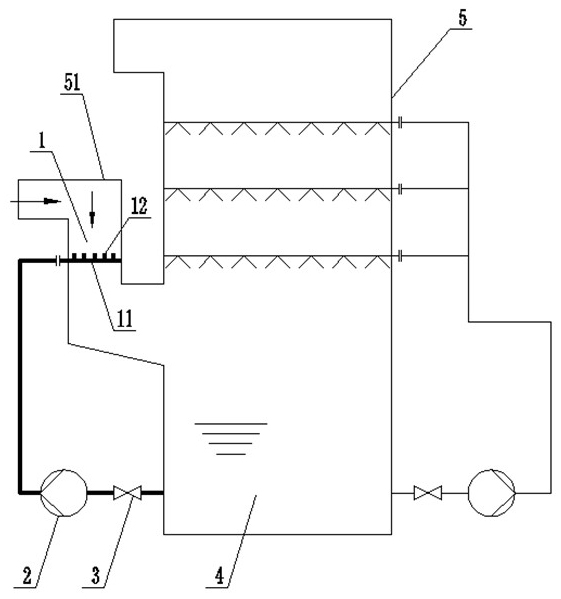

[0014] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. As shown in the figure, the flue gas pre-desulfurization system of the present invention includes a pre-spray device 1 and a pre-circulation pump 2, and the inlet of the pre-circulation pump 2 passes through a valve 3 and a limestone slurry pool 4, the outlet communicates with the pre-spray device 1, and the pre-spray device 1 is arranged in the inlet flue 51 of the desulfurization absorption tower 5.

[0015] In this embodiment, the pre-spraying device 1 is a pipe network type spraying device arranged inside the inlet flue 51, the spraying device covers the entire flue section, and the pre-spraying device 1 includes a spray pipe 11 and The nozzles 12 arranged on the spray pipe 11; the arrangement of the nozzles 12 should be arranged in differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com