Capacitance type vibration sensor

一种振动传感器、静电电容的技术,应用在传感器、静电换能器传声器、半导体静电换能器等方向,能够解决难以制作低干扰振动传感器、振动传感器低频特性变差、振动传感器S/N比变差等问题,达到声音阻抗降低、良好低频特性、减小低频特性的降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

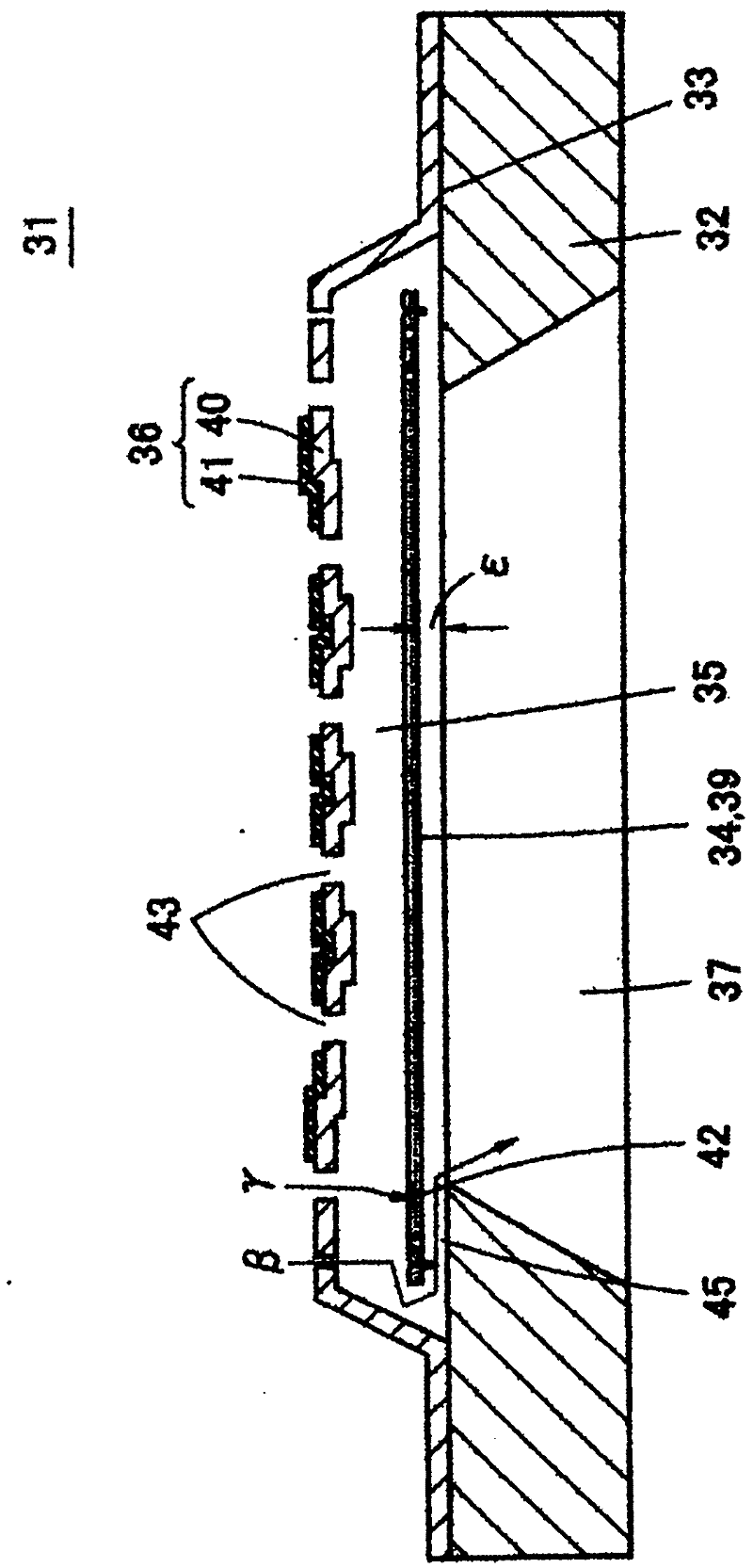

[0073] Below, refer to Figure 3 ~ Figure 7 The first embodiment of the present invention will be described. image 3 It is a schematic cross-sectional view showing the capacitance type vibration sensor 31 of the first embodiment. Figure 4 It is an exploded perspective view of the vibration sensor 31. In addition, Figure 5 It is a plan view of the vibration sensor 31. Image 6 It is a plan view of a state where the fixed electrode plate on the upper surface of the vibration sensor 31 is removed. Figure 7 It is a figure for demonstrating the effect of this embodiment, and shows a part of the cross section of the vibration sensor 31.

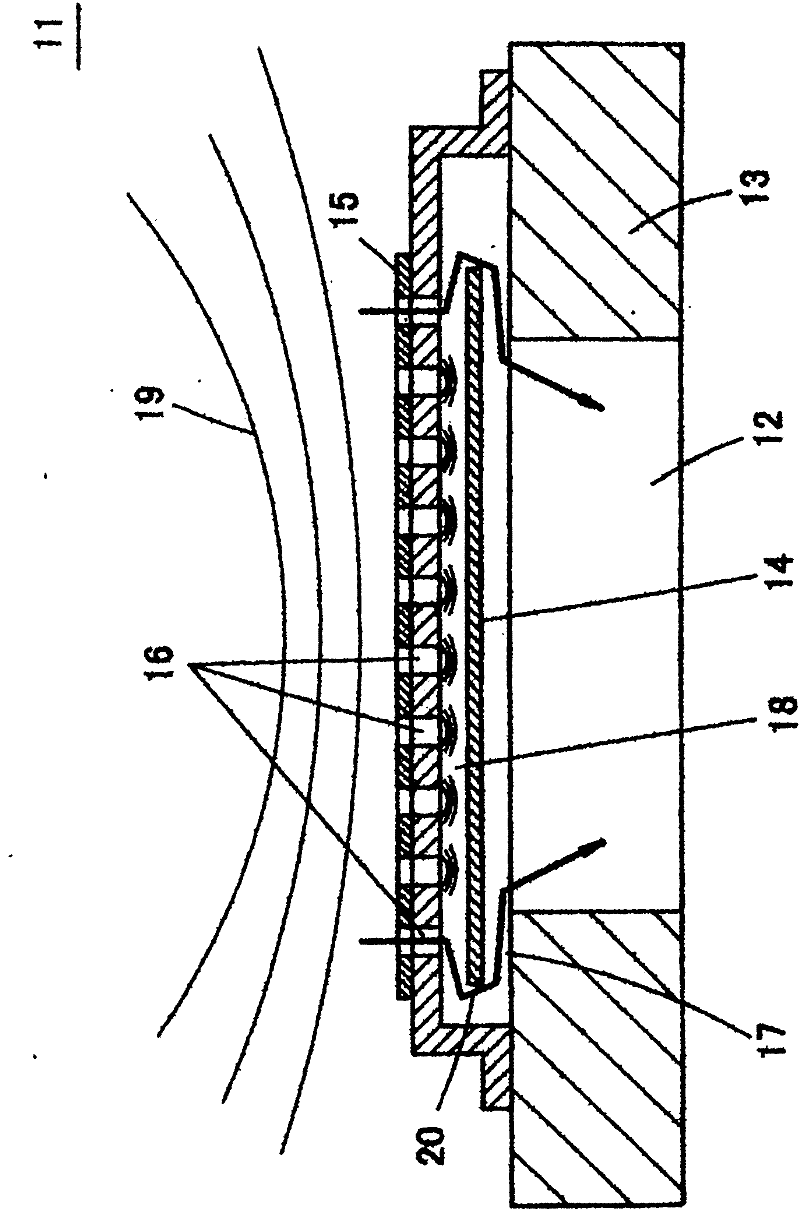

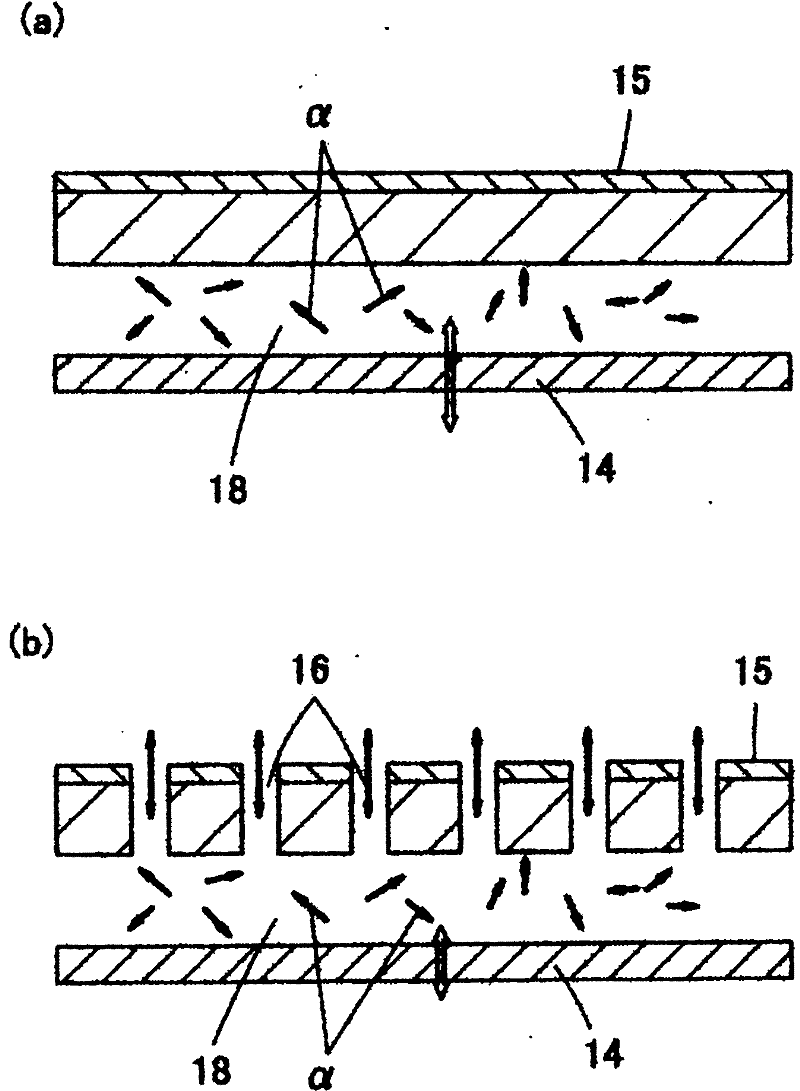

[0074] The vibration sensor 31 is an electrostatic capacitance type sensor. A vibration electrode plate 34 is provided on the upper surface of a silicon substrate 32 via an insulating coating 33, and a fixed electrode plate 36 is provided thereon via a small air gap 35. The vibration sensor 31 is mainly used as a sound sensor and a condenser micro...

no. 2 approach

[0093] Picture 9 (a) is an enlarged cross-sectional view showing a part of the vibration sensor of the second embodiment, Picture 9 (b) is a plan view showing a part of the silicon substrate 32 located around the cavity 37. In this embodiment, the exhaust portions 51 and 52 are provided on the base plate 42 at positions where the ventilation holes 45 are provided. The exhaust portion 51 is a through hole that penetrates the silicon substrate 32 up and down, and the exhaust portion 51 is a bottomed recess (that is, a hole blocked on one side).

[0094] In the case of the through-hole-shaped exhaust portion 51, like the exhaust portion 42 of the first embodiment, it is possible to reduce the interference due to thermal noise without reducing the acoustic impedance of the vent hole 45.

[0095] In the case of the concave exhaust portion 52, the distance between the bottom surface of the concave portion and the lower surface of the vibrating electrode plate 34 becomes longer by provi...

no. 3 approach

[0098] Picture 10 Is an enlarged cross-sectional view showing a part of the vibration sensor of the third embodiment, Picture 11 It is a plan view of the silicon substrate 32 used in this vibration sensor. In this embodiment, in the ventilation hole 45, a groove-shaped exhaust portion 61 is provided on the upper surface of the silicon substrate 32 so as to surround the cavity 37. In the illustrated example, two exhaust portions 61 are provided, but there may be one, and as long as the acoustic impedance is not too low, there may be three or more. In addition, the groove of the exhaust part 61 does not need to be annular, and linear grooves may be formed along each side.

[0099] In such an embodiment, as in the case of the first and second embodiments, the interference caused by the thermal noise in the vent hole 45 can be reduced, and the good low-frequency characteristics can be made difficult to reduce.

[0100] In addition, in the vent hole 45, a groove-shaped exhaust portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com