Substrate-inspecting device having cleaning mechanism for tips of pins

A substrate inspection and cleaning mechanism technology, which is applied to the cleaning method using tools, measuring devices, cleaning methods, and tools, can solve the problems of uneven cleaning levels at the top of pins, long total time, etc., and achieve good efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

[0108] [Outline of Rotary Table Devices in Other Embodiments]

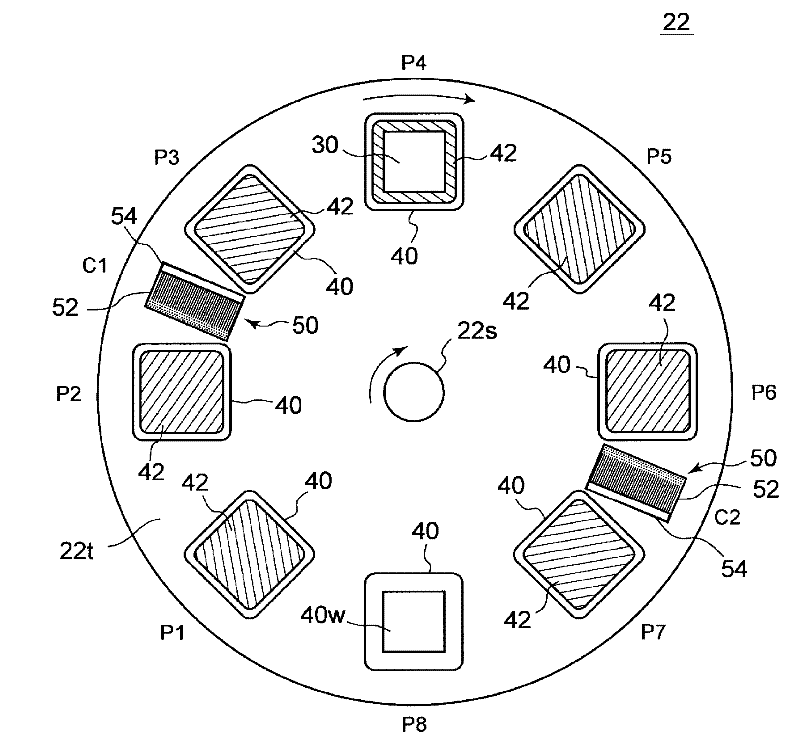

[0109] Figure 7 is viewed from above with figure 2 A plan view of a turntable device 220 according to another embodiment. for with figure 2 The same elements of the turntable device 22 are denoted by the same reference numerals, and description thereof will be omitted.

[0110] and figure 2 is different from the rotary table device 22, in place of the cleaning mechanism 50 at the position C1 on the circular table 22t between the inspection target substrate holding unit 40 at the position P2 and the inspection target substrate holding unit 40 at the position P3, along the In the radial direction, an upper pin tip end cleaning member 44Ru is provided. Therefore, the pin tip cleaning member 44Ru moves along the same path as the above-mentioned transport path on which the substrate 42 to be inspected is transported, integrally with the turntable 22 device. In addition, this installation position is arbitrary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com