Apparatus for treating discharge gas and system for treating discharge gas

A waste gas treatment device and waste gas technology, which are applied in gas treatment, combustion product treatment, climate sustainability, etc., can solve the problems of limited contact area of denitration catalyst, difficulty in further improving the efficiency of mercury oxidation reaction, etc., and increase the contact time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

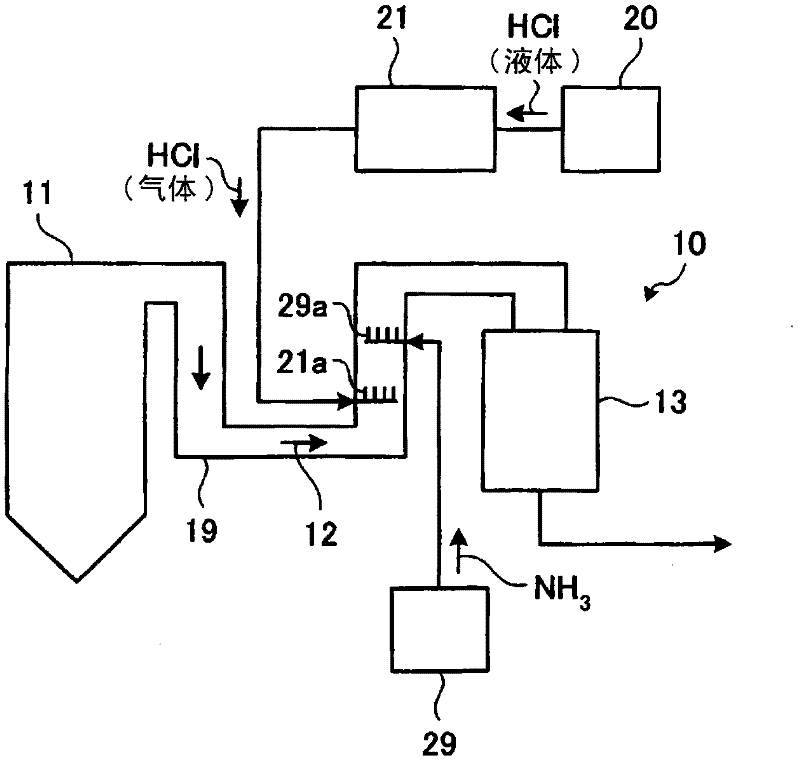

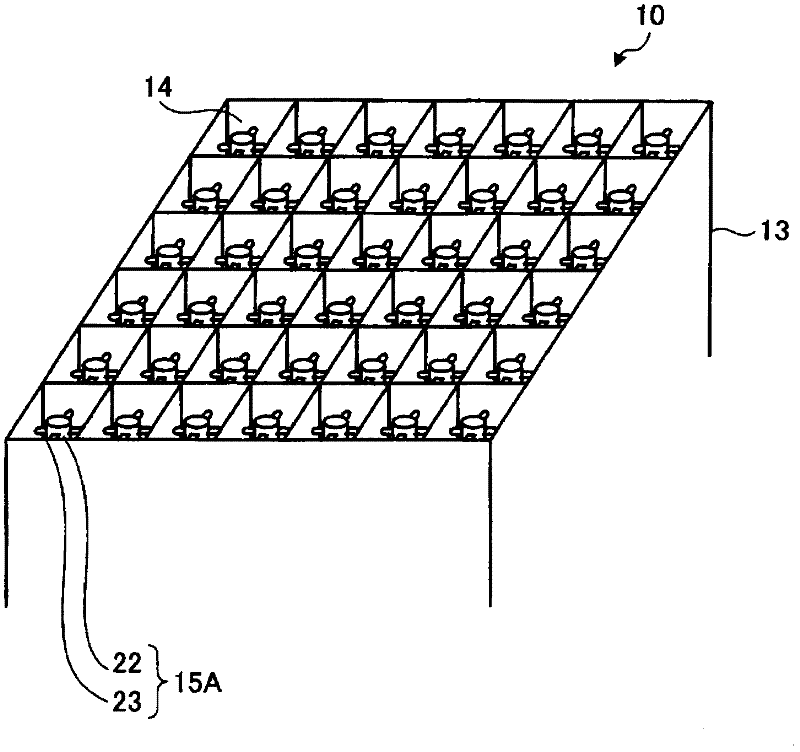

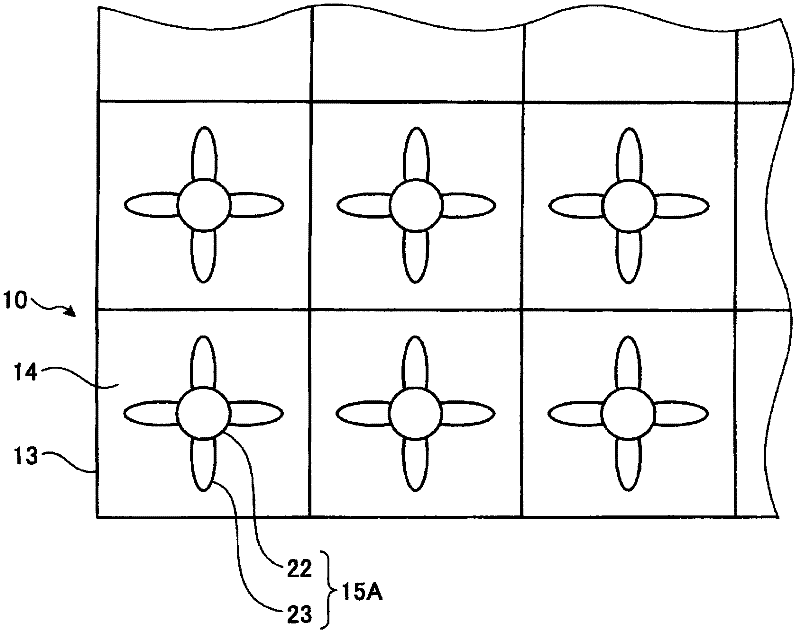

[0050] An exhaust gas treatment system to which an exhaust gas treatment device according to an embodiment of the present invention is applied will be described with reference to the drawings. In addition, since the structure of the exhaust gas treatment system to which the exhaust gas treatment device of this embodiment is applied Figure 12 The shown exhaust gas treatment systems have the same structure, so in this embodiment, only the structure of the exhaust gas treatment device will be described.

[0051] figure 1 is a schematic diagram showing an exhaust gas treatment device of an embodiment, figure 2 is a perspective view showing a part of the structure of the denitration catalyst layer, image 3 is a diagram when the swirling flow generating member is viewed from a direction perpendicular to the vertical axis direction, Figure 4 This is a diagram when the swirling flow generating member is viewed from the vertical axis direction of the denitration catalyst layer. ...

Embodiment 2

[0076] An exhaust gas treatment system to which an exhaust gas treatment device according to an embodiment of the present invention is applied will be described with reference to the drawings. In addition, in this embodiment, similarly to Embodiment 1, since the structure and Figure 12 The shown exhaust gas treatment systems have the same structure, so in this embodiment, only the structure of the exhaust gas treatment device will be described.

[0077] In addition, since the structure of the exhaust gas treatment device of this embodiment is the same as the exhaust gas treatment device of the above-mentioned first embodiment, the diagram showing the structure of the exhaust gas treatment device will be omitted, and only the figure showing the structure of the swirling flow generating member will be used for description. .

[0078] Figure 5 is a diagram when the swirling flow generating member is viewed from a direction perpendicular to the vertical axis direction, Image ...

Embodiment 3

[0084] An exhaust gas treatment system to which an exhaust gas treatment device according to an embodiment of the present invention is applied will be described with reference to the drawings. In addition, in this example, similarly to Example 1, the structure and Figure 12 The shown exhaust gas treatment systems have the same structure, so in this embodiment, only the structure of the exhaust gas treatment device will be described.

[0085] In addition, since the structure of the exhaust gas treatment device of this embodiment is the same as the exhaust gas treatment device of the above-mentioned embodiment 1, the diagram showing the structure of the exhaust gas treatment device is omitted, and only the figure showing the structure of the swirling flow generating part is used. illustrate.

[0086] Figure 7 is a diagram when the swirling flow generating member is viewed from a direction perpendicular to the vertical axis direction, Figure 8 This is a diagram when the swir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com