Long-stroke DC linear motor and control system thereof

A linear motor and control system technology, applied in the direction of AC motor control, control system, propulsion system, etc., can solve the problems of high power and high precision, improve linearity, reduce winding inductance and magnetic circuit cross-sectional area, The effect of suppressing thrust fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

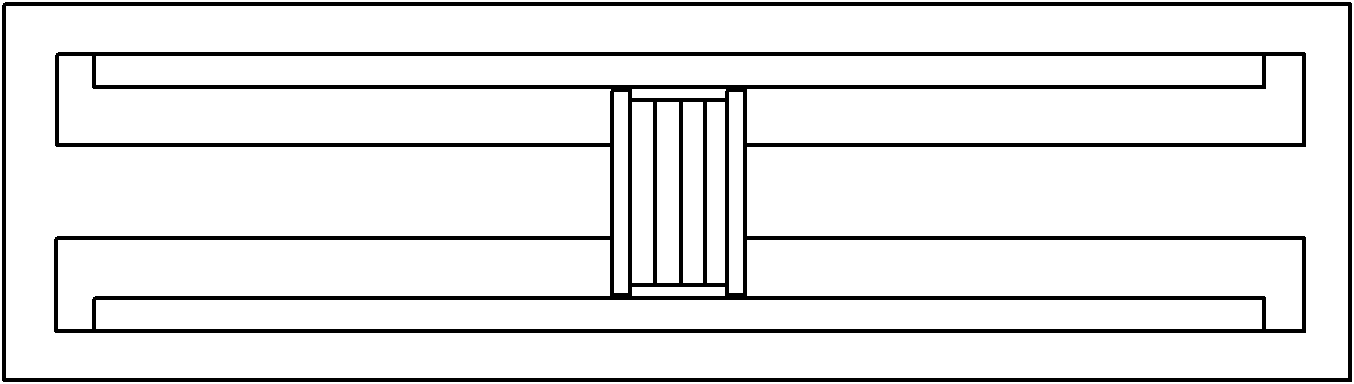

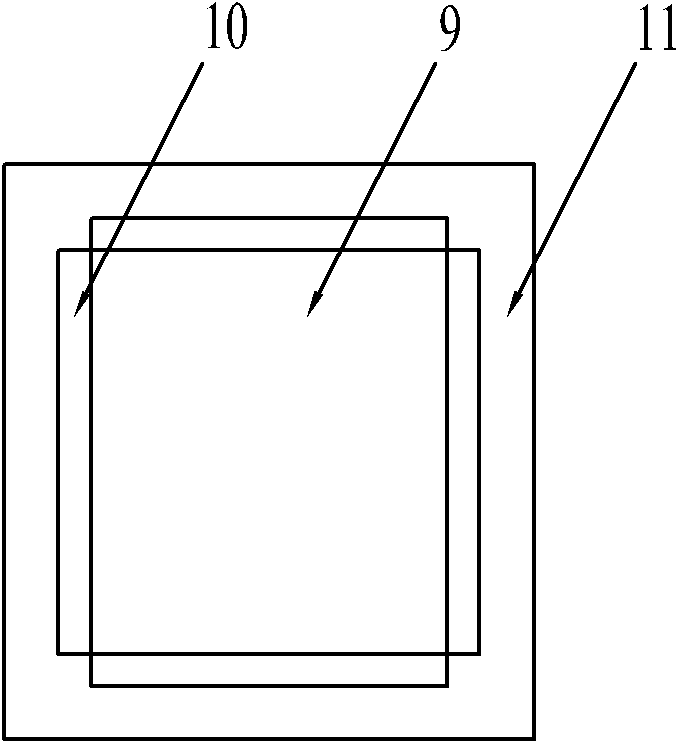

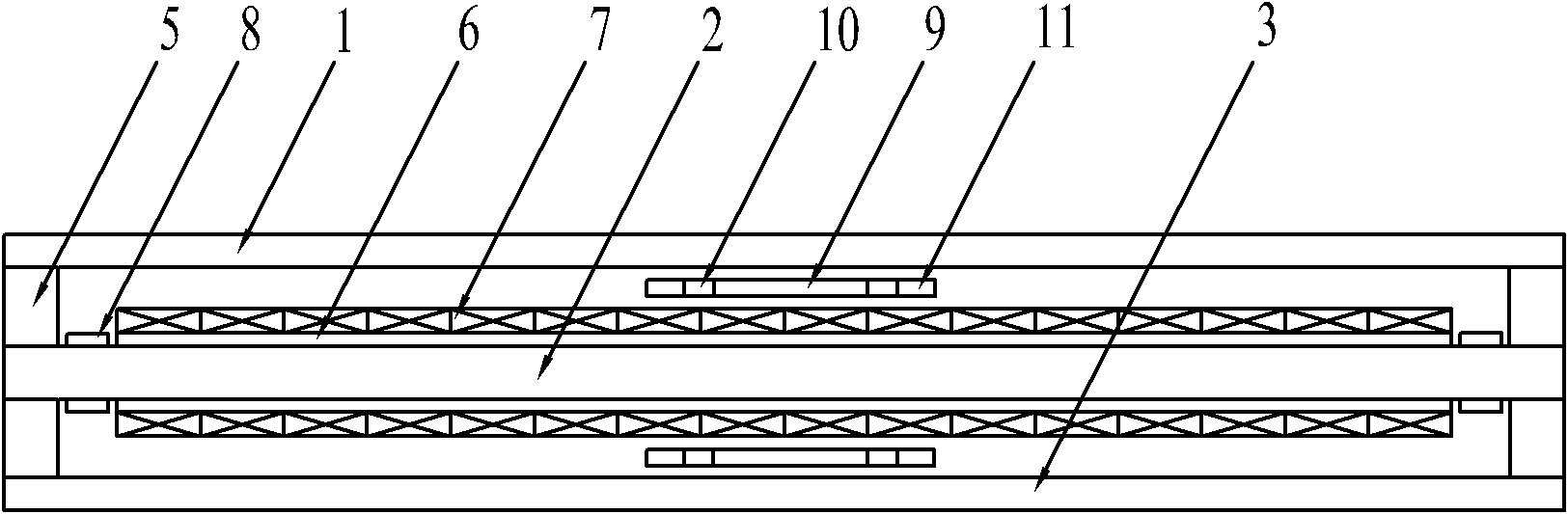

[0021] Specific implementation mode one: combine figure 2 Describe this embodiment, this embodiment is made up of primary and secondary; There is an air gap between said primary and secondary; , a power winding 7 and an even number of compensation windings 8;

[0022] The magnetic yoke part is composed of an upper magnetic yoke 1, a middle magnetic yoke 2, a lower magnetic yoke 3 and two side magnetic yokes 4; an upper magnetic yoke 1, a middle magnetic yoke 2 and a lower magnetic yoke 3 are arranged parallel to each other; the setting directions of the upper magnetic yoke 1, the middle magnetic yoke 2 and the lower magnetic yoke 3 are all parallel to the direction of motion; the upper magnetic yoke 1, the middle magnetic yoke 2, the lower magnetic yoke 3 and the The two lateral guide yokes 4 are enclosed to form a rectangular guide yoke part;

[0023] The even number of flat permanent magnets 5 are respectively arranged on the magnetically permeable yoke parts;

[0024] T...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination image 3 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the number of the compensation winding 8 is two; Two compensation windings 8 are located at both ends of the control winding 6 respectively. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Figure 4 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the number of the compensation windings 8 is four; the four compensation windings 8 are divided into two groups; On the two lateral guide yokes 4 between the magnetic guide yoke 1 and the middle guide yoke 2; the other set of compensation windings 8 are respectively installed on the two side guide magnetic yokes between the lower guide yoke 3 and the middle guide yoke 2 Yoke 4 on. Other compositions and connection methods are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com