Mechanical locking device for packer

A mechanical locking and packer technology, applied in wellbore/well components, earthwork drilling, etc., can solve the problems of inappropriate replacement of multi-flow testers, limited drill collar weight, increased labor intensity, etc. Success rate, reduced labor intensity, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

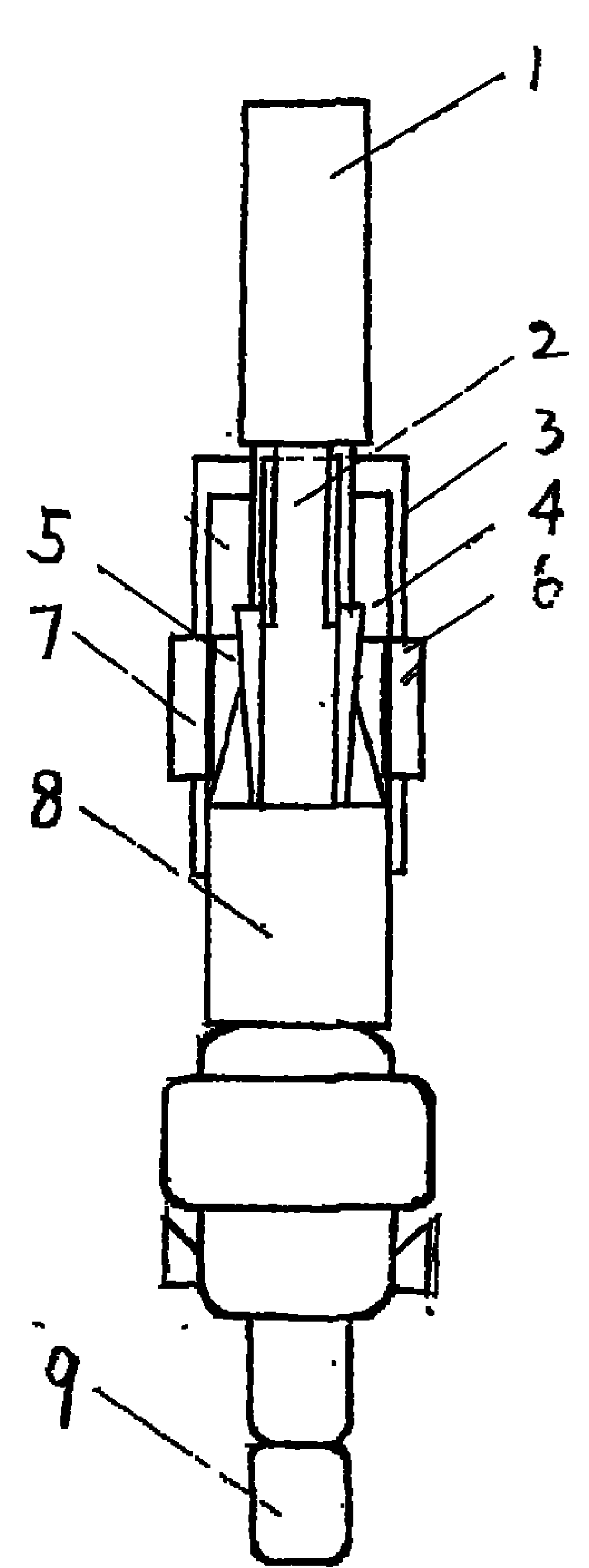

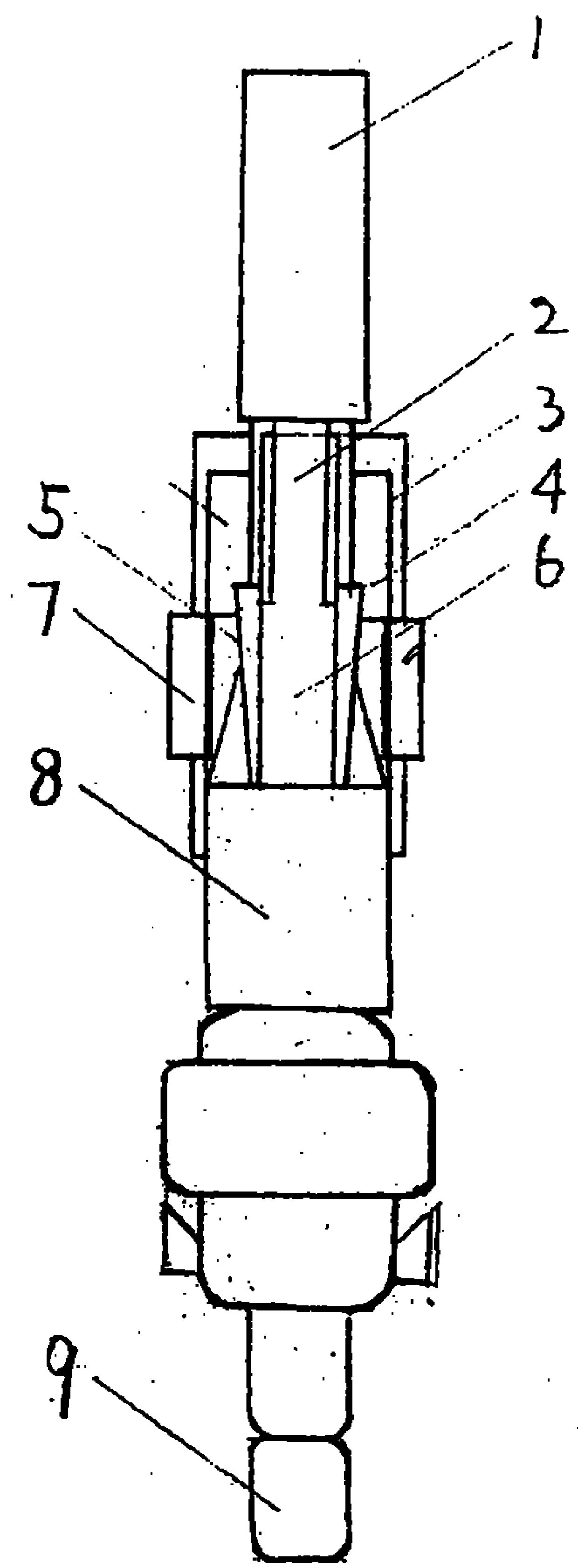

[0013] The present invention will be further described in conjunction with accompanying drawings.

[0014] Such as figure 1 As shown, take the joint test tube as an example.

[0015] Pipe string structure: from bottom to top, the test string is perforating gun, shock absorber, screen, packer, VR, safety joint, mechanical lock, expansion joint, pressure gauge, multi-flow tester, circulation valve , tubing string.

[0016] Drilling down: In the process of lowering the test tube, if there is no resistance, the mechanical locking mandrel will not go down, and the slips in the anchoring mechanism will not move in place.

[0017] Set the packer and open the well: After the test string is lowered to the predetermined position, the sealer is set, and the multi-flow tester test valve and mechanical lock are delayed under the action of the delay mechanism. After the packer is set, At the end of the mechanical locking delay, the reverse slips in the mechanical locking and anchoring me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com