Through-tunnel lower pilot girder type non-moving lifting bridge girder erection machine

A technology of bridge hanger and tunnel crossing, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of inability to achieve short-distance beam erection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

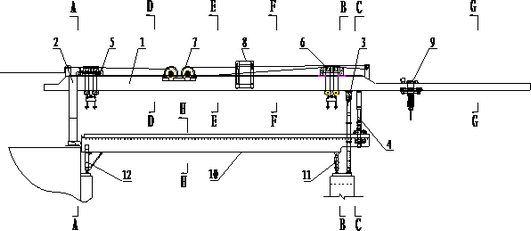

[0035] Embodiment 1: The lifting bridge erecting machine includes a beam erecting machine and a lower guiding beam machine; the beam erecting machine includes a main beam 1, an O-shaped rear outrigger 2, a foldable front outrigger 3, an auxiliary outrigger 4, and a front hanger Beam crane 5, rear crane beam crane 6, winch assembly 7, guide beam crane 8, guide beam passing crane 9, lower guide beam main beam 10 guide beam front outrigger 11 and guide beam rear outrigger 12 A foldable front outrigger 3 and an auxiliary outrigger 4 are connected to the bottom surface of the front part of the main beam 1, and an O-shaped rear outrigger 2 is connected to the rear end of the main beam; Hanging beam crane 6, winch assembly 7 is installed in the middle of the main beam, guide beam crane 8 and guide beam passing crane 9 are connected on the track on the upper end surface of main beam 1, guide beam passing crane 9 is located on the main beam 1 front end; the lower guide beam machine inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com