Gas supply equipment

A gas supply and equipment technology, applied in the field of plasma-assisted chemical vapor deposition systems, can solve the problems of local plasma generation, blocking RPS gas outlet, shortening the service life of remote plasma sources, etc., to improve deposition rate and improve cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Please refer to the drawings below so that the technology of the present invention can be more fully understood. Although embodiments of the invention are shown herein in the drawings, the invention can be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. In the drawings, for the sake of clarity, the sizes and relative sizes of the components and regions are not drawn in true scale.

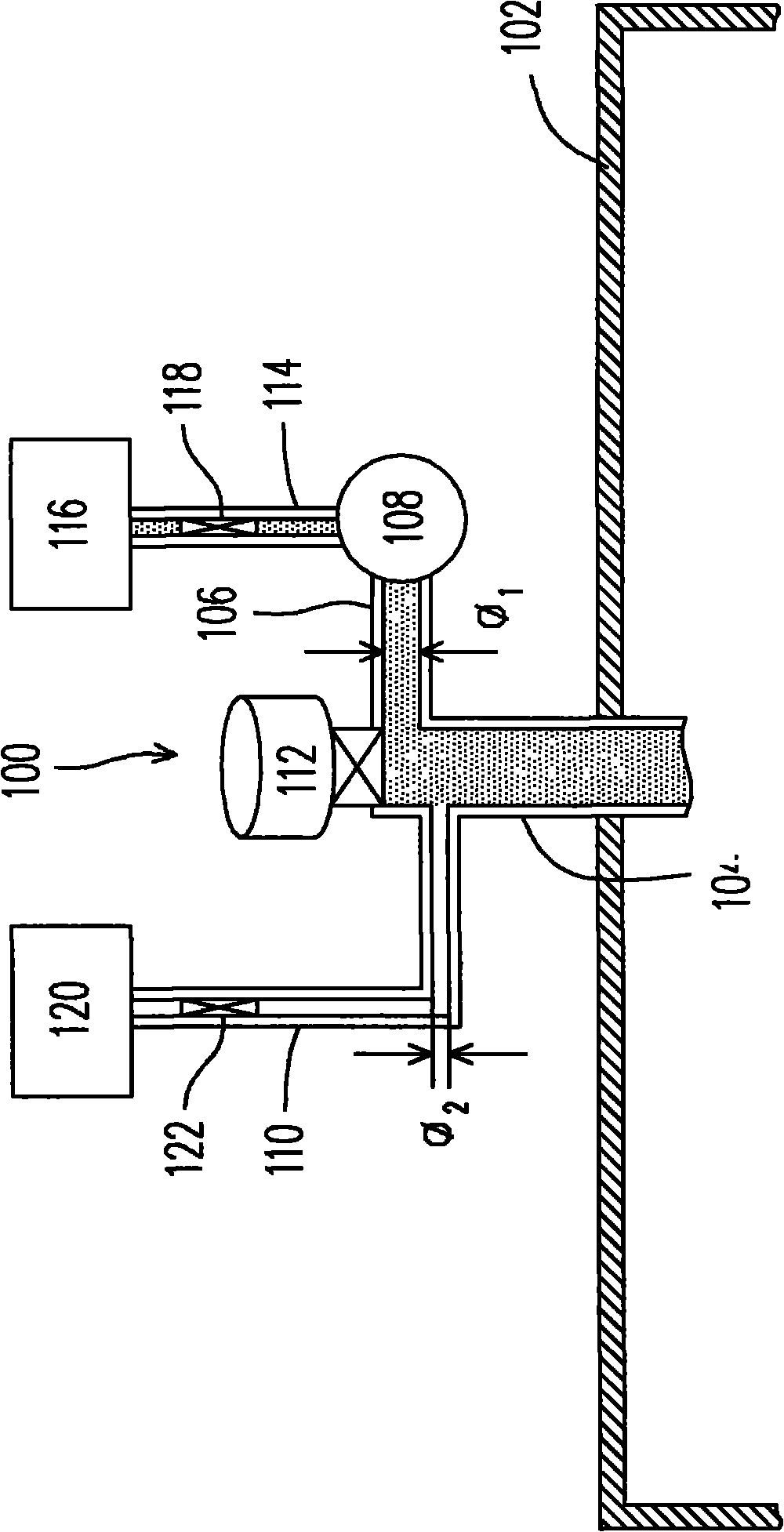

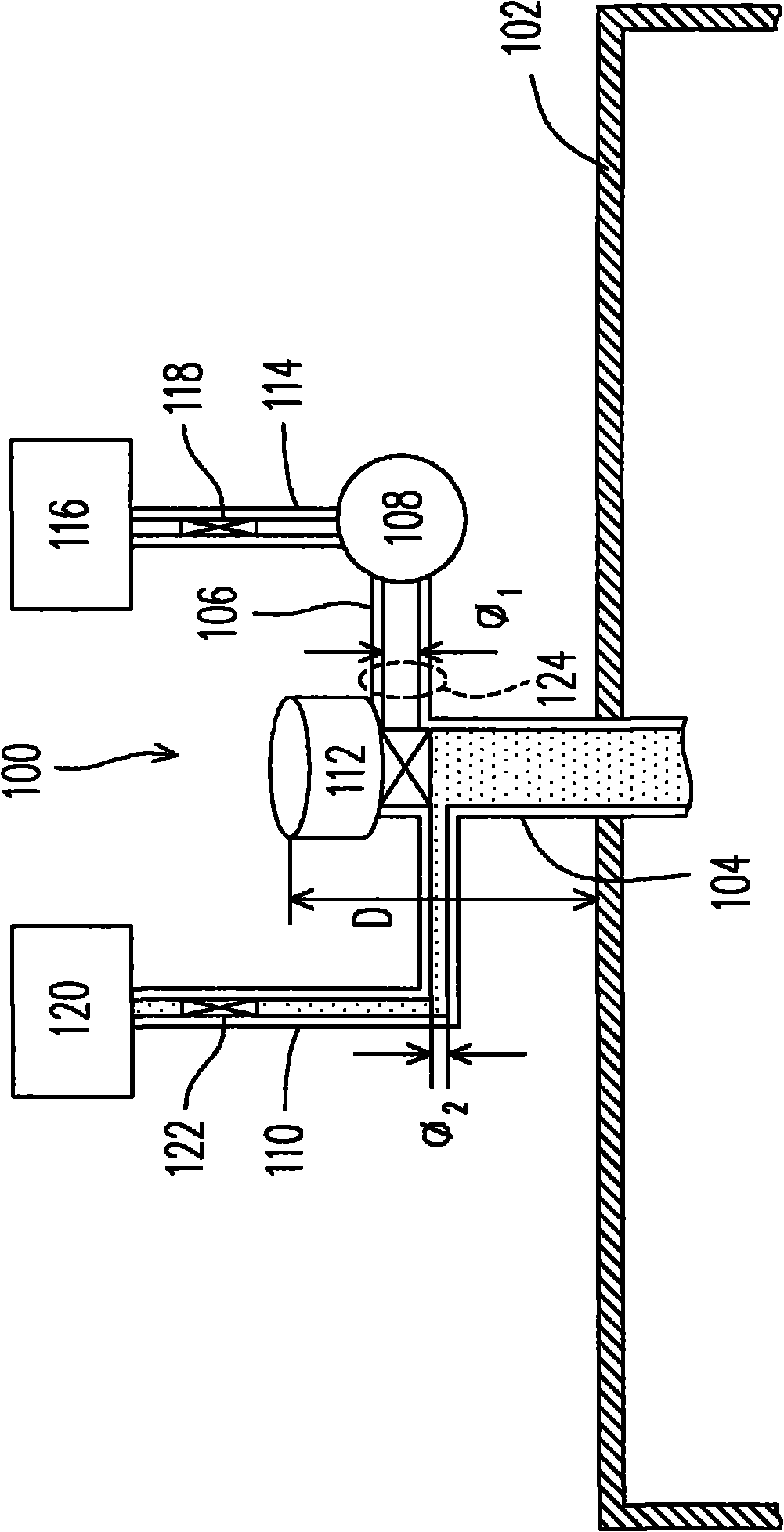

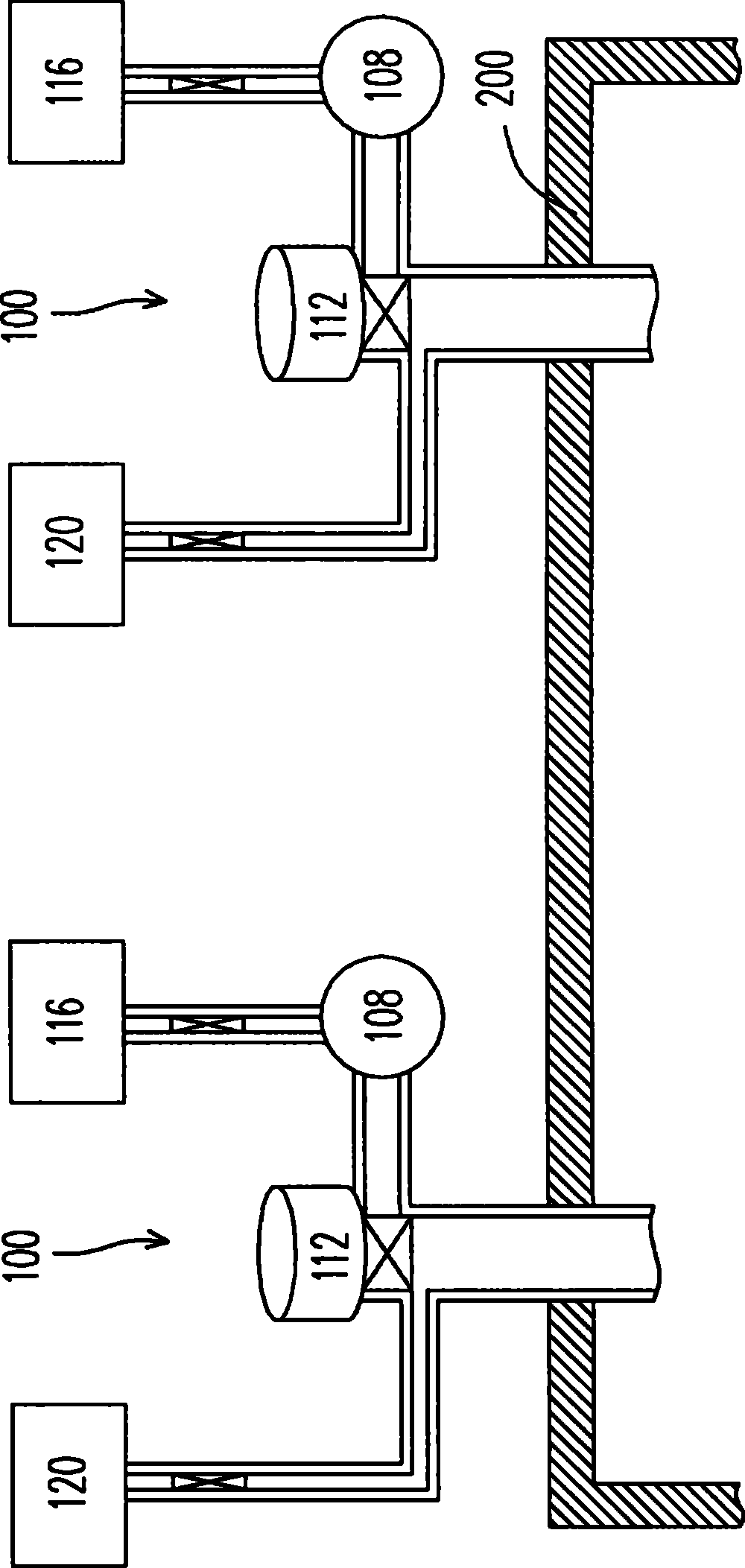

[0045] Figure 1A and Figure 1B is a schematic diagram of the operation of a gas supply device according to the first embodiment of the present invention.

[0046] Please refer to Figure 1A , the gas supply device 100 of the first embodiment is used to guide gas to a process chamber 102 of a plasma-assisted chemical vapor deposition (PECVD) system. The gas supply equipment 100 of Fig. 1 comprises the inlet pipe 104 that enters the process chamber 102 from the outside of the process chamber 102, a clean gas pipe 106, a remote pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com