Agitator blade for improving leaching rate of metal manganese electrolyte

An electrolyte and metal manganese technology, applied in the field of stirring paddles, can solve problems such as increasing energy consumption, and achieve the effects of reducing energy consumption, low equipment cost and simple structure

Inactive Publication Date: 2011-06-15

CHONGQING UNIV

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As a result of doing so, although some leaching rates can be improved, energy (electricity) consumption will be increased

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

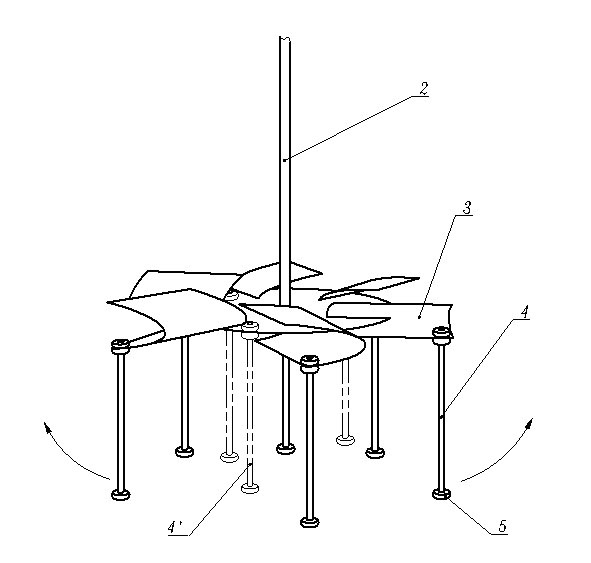

The invention discloses an agitator blade for improving the leaching rate of metal manganese electrolyte. A plurality of layers of agitator blades are arranged, and are fixedly arranged on an agitating shaft coaxial with a leaching groove for the metal manganese electrolyte. The outer end of each agitator blade in each layer of agitator blades is fixedly suspended with a flexible belt; the length of the flexible belt of the agitator blade positioned on the upper layer meets the conditions that: the flexible belt in the vertical state cannot be scratched by the agitator blade on the lower layer, and when the flexible belt is unfolded due to centrifugal force and rotates in ore pulp, the flexible belt cannot be scratched by the side wall of the leaching groove; and the length of the flexible belt of the agitator blade positioned at the lowest layer meets the conditions that: the flexible belt in the vertical state cannot be scratched by a corresponding part at the bottom of the leaching groove, and when the flexible belt is unfolded due to centrifugal force and rotates in the ore pulp, the flexible belt cannot be scratched by the side wall of the leaching groove. The agitator blade can eliminate stirring dead zones under the condition of not increasing energy consumption basically, so the leaching rate of the metal manganese electrolyte can be improved. The agitator blade has the advantages of simple structure and low equipment cost.

Description

Stirring paddle for improving leaching rate of metal manganese electrolyte technical field The invention relates to a stirring paddle in a metal manganese electrolyte leaching tank. Background technique In enterprises that produce electrolytic manganese metal (referred to as electrolytic manganese) by electrolysis, most of them use manganese carbonate (rhodochrosite) as raw material, prepare them into pulp and put them in a leaching tank to leach the electrolyte, and then perform electrolysis. In order to ensure sufficient leaching, stirring paddles for stirring ore pulp are installed in the leaching tanks. The specific structure is that a stirring shaft coaxial with the leaching tank is set in the leaching tank, which is driven by a motor to rotate, and several layers of stirring paddles that are all immersed in the ore pulp are set on the stirring shaft (the number of layers of the stirring paddles According to the depth of the actual leaching tank). When leaching the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B3/02C22B3/04B01F7/18C22B47/00

CPCY02P10/20

Inventor 刘作华宁伟征陶长元孙瑞祥周小霞杜军范兴刘仁龙曾启琴彭浩廖军

Owner CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com