Mixed steel and wood floor for railway flatcars

A steel floor and wooden floor technology, applied in the direction of railway car body, railway car body parts, axle box lubrication, etc., can solve the problem of affecting the performance of railway flat cars, low rolling strength of wooden floor, and easy damage of floor layering, etc. problems, to achieve the effect of convenient local maintenance, easy replacement, and reduced use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

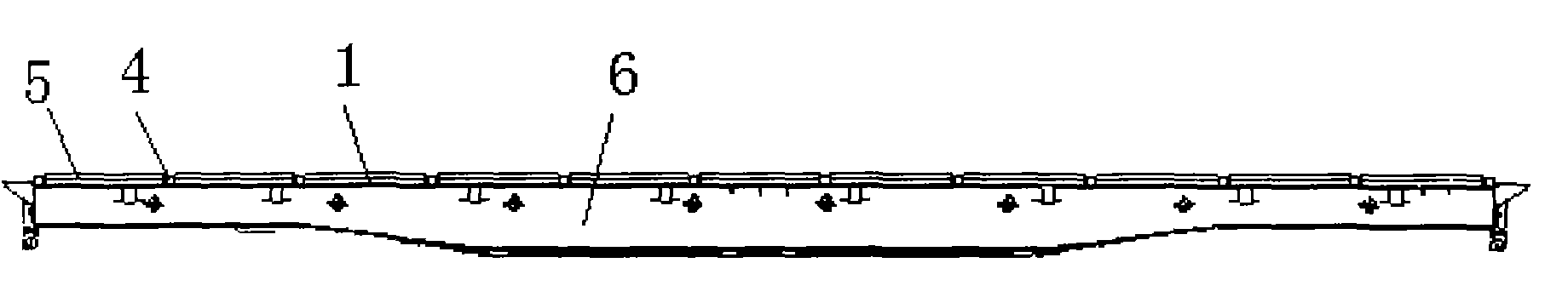

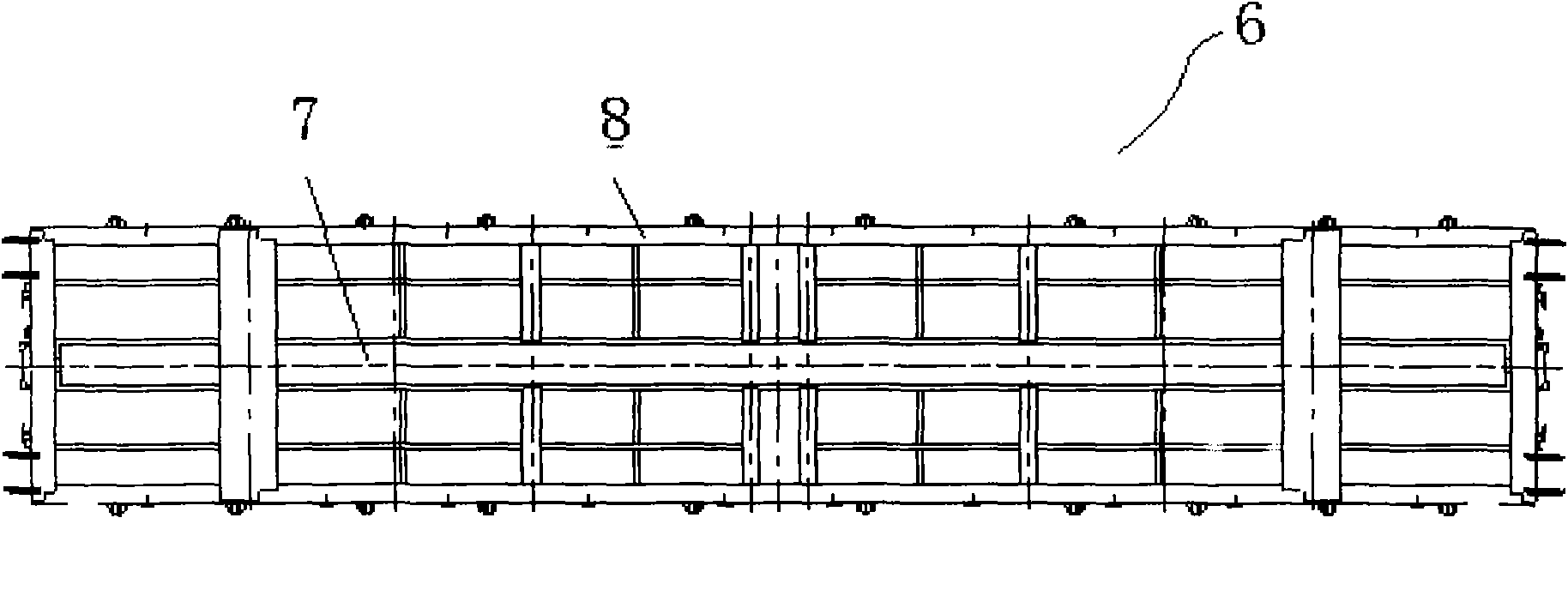

[0014] Such as figure 1 , figure 2 As shown, the present invention includes four rows of side weight irons 1 arranged side by side at intervals, and each row of side weight irons 1 is composed of several side weight irons 1 connected end to end. The two ends of the four rows of side weights 1 are fixedly connected with a steel floor 2 respectively, and a central steel floor 3 is arranged between the two rows of side weights 1 in the middle, and the two rows of side weights 1 on each side of the central steel floor 3 Several side steel floors 4 are arranged at intervals, and each side steel floor 4 is arranged perpendicular to the side weight iron 1, and a wooden floor 5 is arranged between every two adjacent side steel floors 4. The upper surfaces of the side pressure iron 1, the steel floor 2, the central steel floor 3 and the side steel floor 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com