Adjustable installation mechanism of exhaust system of light truck

A technology of exhaust system and installation mechanism, which is applied in the direction of power plant, vehicle parts, transportation and packaging, etc., which can solve the problems of troublesome installation and scrapping, and achieve the effects of simple structure, overcoming manufacturing errors and assembly errors, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

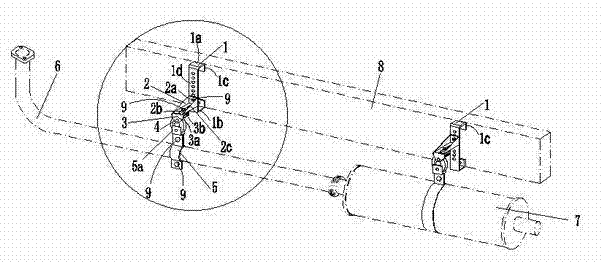

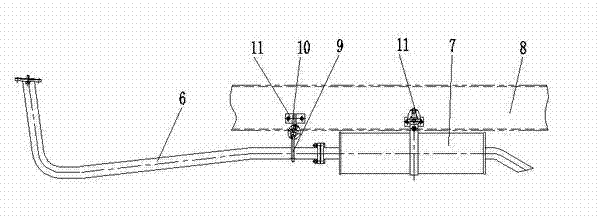

[0021] Such as figure 1 A light truck exhaust system shown (indicated by a dotted line in the figure) is composed of an exhaust pipe 6 and a muffler 7, and the tail end of the exhaust pipe 6 and the front end of the muffler 7 are connected together by bolts. The adjustable installation mechanism of the light truck exhaust system (indicated by the solid line in the figure) consists of the installation support 1, the first adjustment bracket 2, the second adjustment bracket 3, the shock-absorbing rubber pad 4, the hoop 5, the bolt 9 and Cotter pin shaft, cotter pin (not shown in the figure) etc. are formed.

[0022] Such as figure 1 , figure 2 As shown, the mounting support 1 is C-shaped as a whole, and is composed of an upper plane 1a, a lower plane 1b, a front plane 1c and a rear plane 1d. A transverse gap is opened on the front plane 1c, which divides t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com