Precise control device for rolling force of lower fillet of high-strength bolt head

A high-strength bolt and precise control technology, applied in the field of control, can solve the problems of unguaranteed product quality consistency, no automatic compensation adjustment function, affecting product processing quality, etc., and achieves easy implementation, simple structure, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

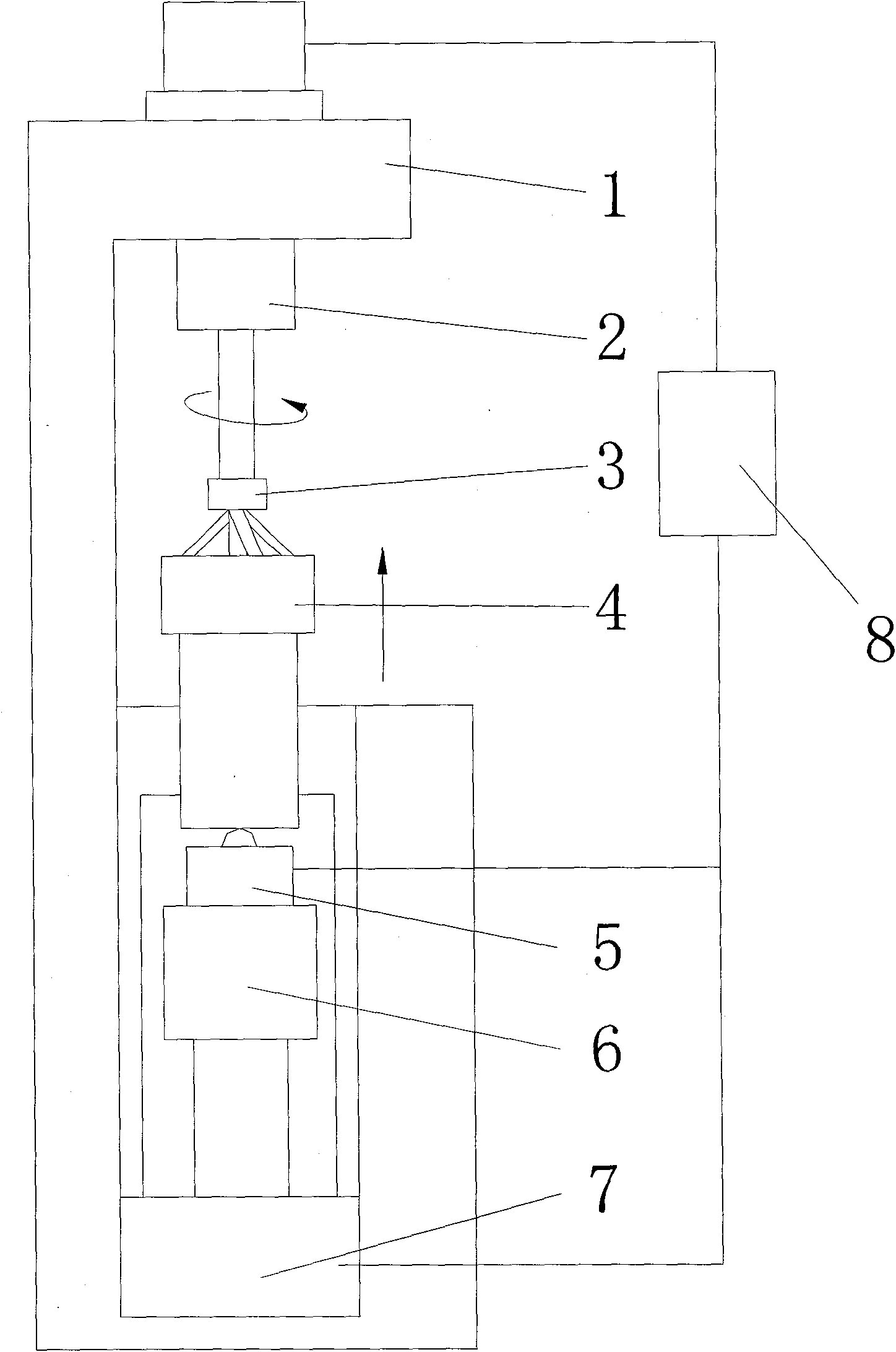

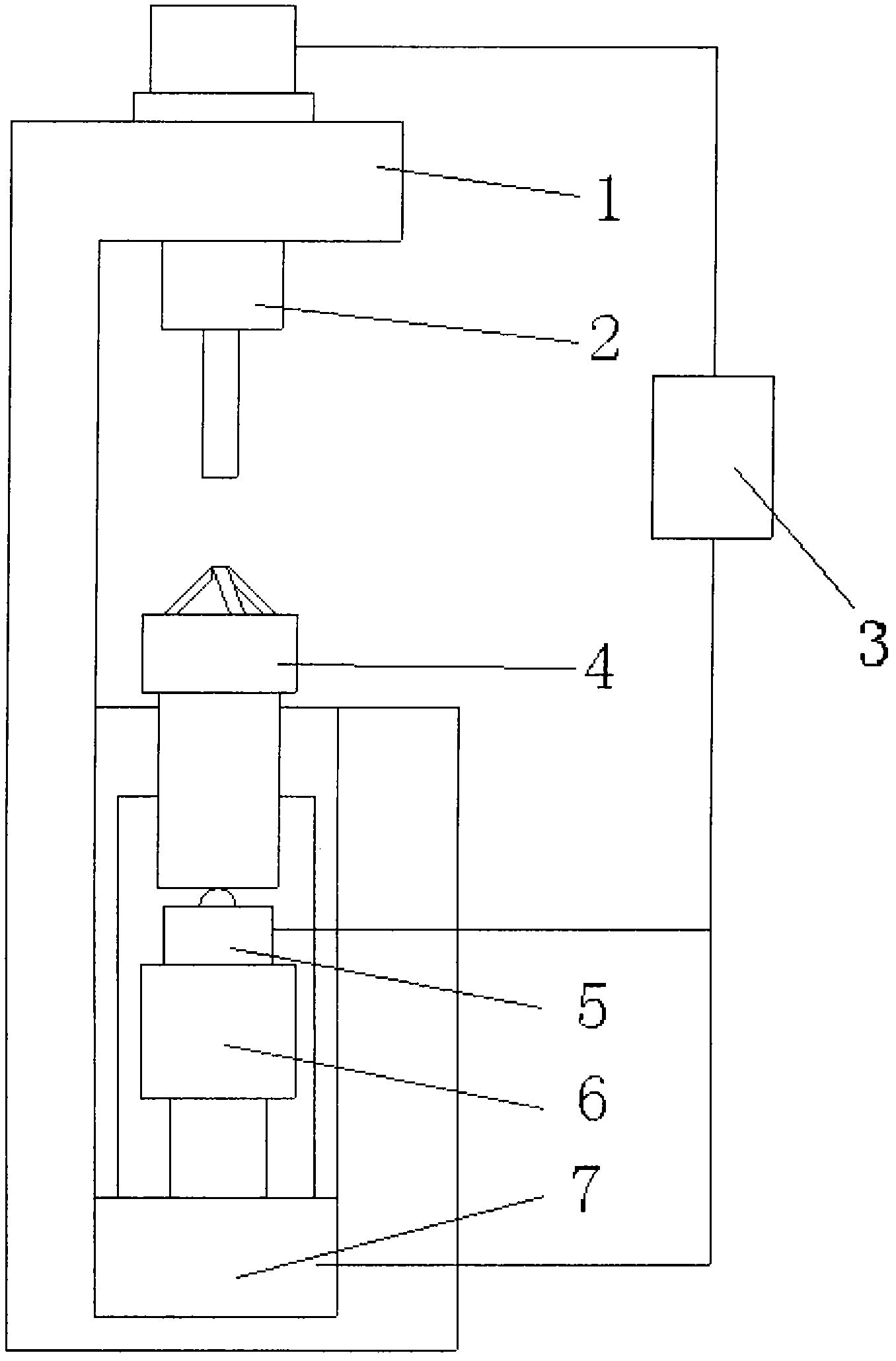

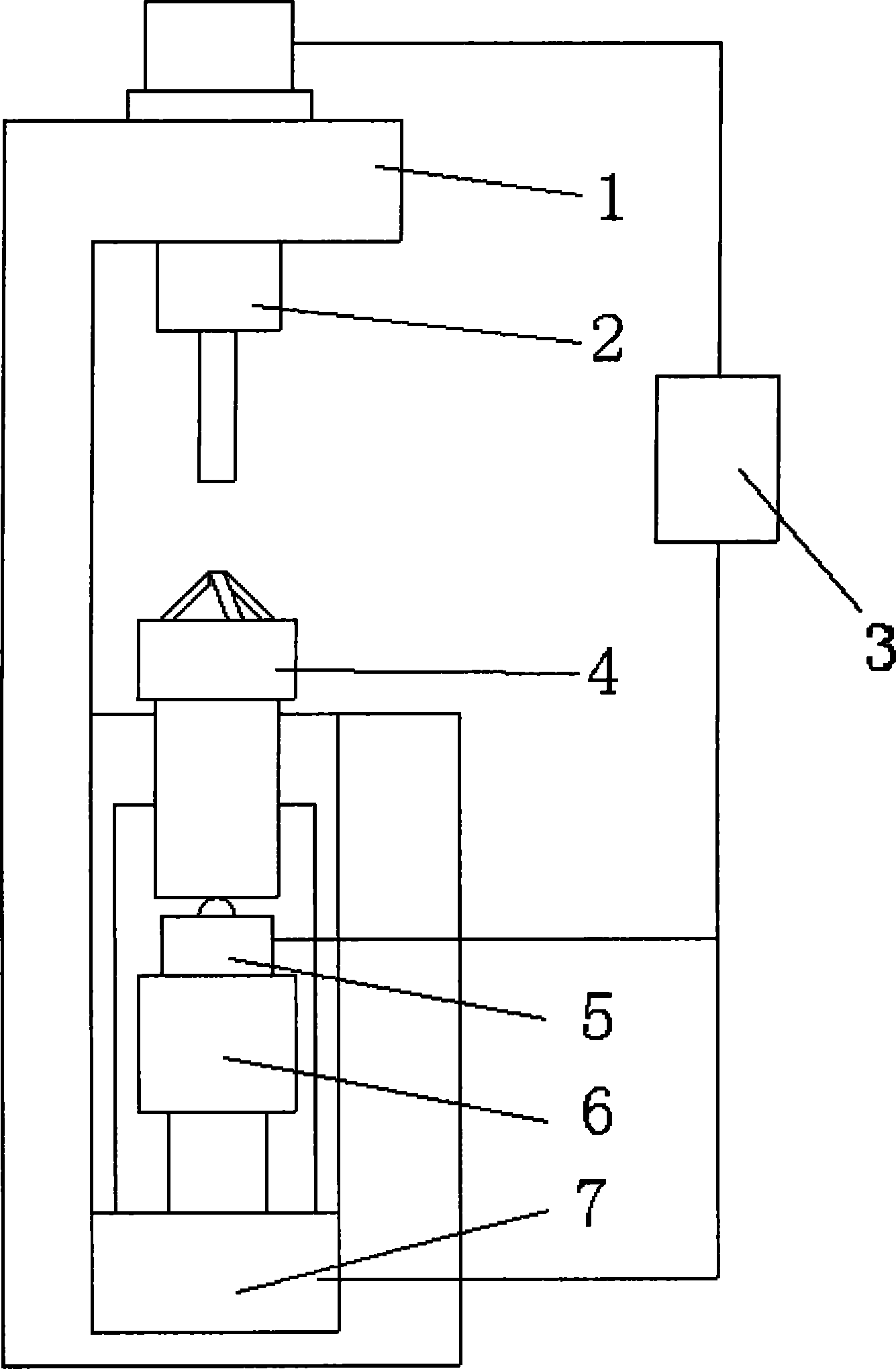

[0010] The specific implementation, structure, features and effects of the precise control device for the lower fillet rolling pressure of the high-strength bolt head according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments:

[0011] See figure 1 , The precise control device for the round corner rolling pressure of the high-strength bolt head, including the servo drive device 7, the elastic compensation system 6, the force sensor 5, the bolt rolling device 4, the spindle system 2, the control system 3. The spindle system 2 is fixed on the upper part of the frame 1 through bearings, the housing of the servo drive device 7 is fixed on the lower part of the frame 1, the elastic compensation system 6 is fixed on the servo drive device 7, and the bolt rolling device 4 is installed on the elastic compensation system 6 Above, the control system 3 is connected with the spindle system 2, the servo drive devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com