Three-dimensional mixer and three-dimensional mixing method

A mixing machine, three-dimensional technology, applied in the direction of mixers, chemical instruments and methods, mixers with rotating containers, etc., can solve the problems of reduced service life of the main shaft, inapplicability, and far away rotation center of gravity, etc., to achieve mixing effect and Efficiency improvement, convenient hoisting and disassembly, and easy processing to achieve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

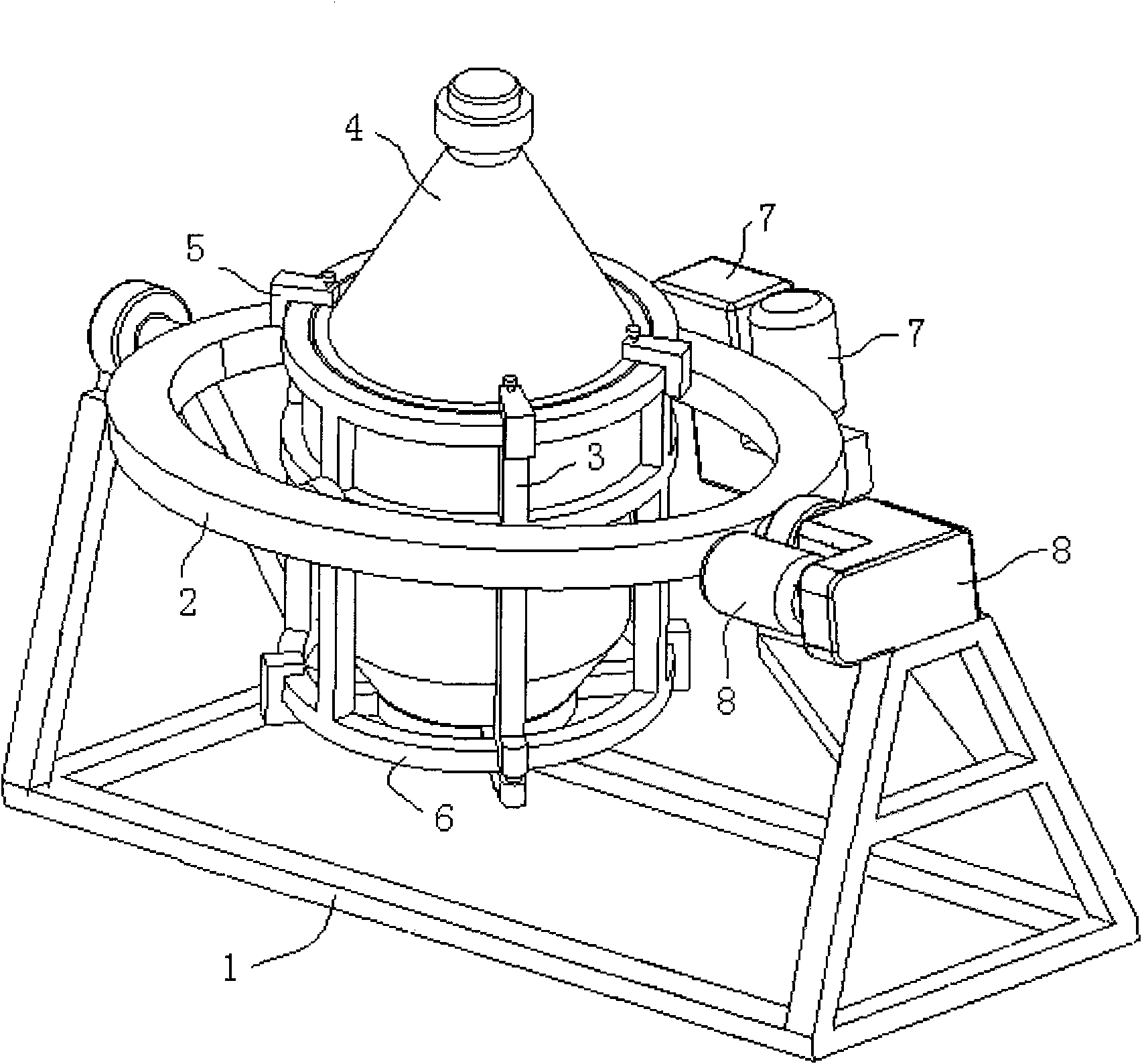

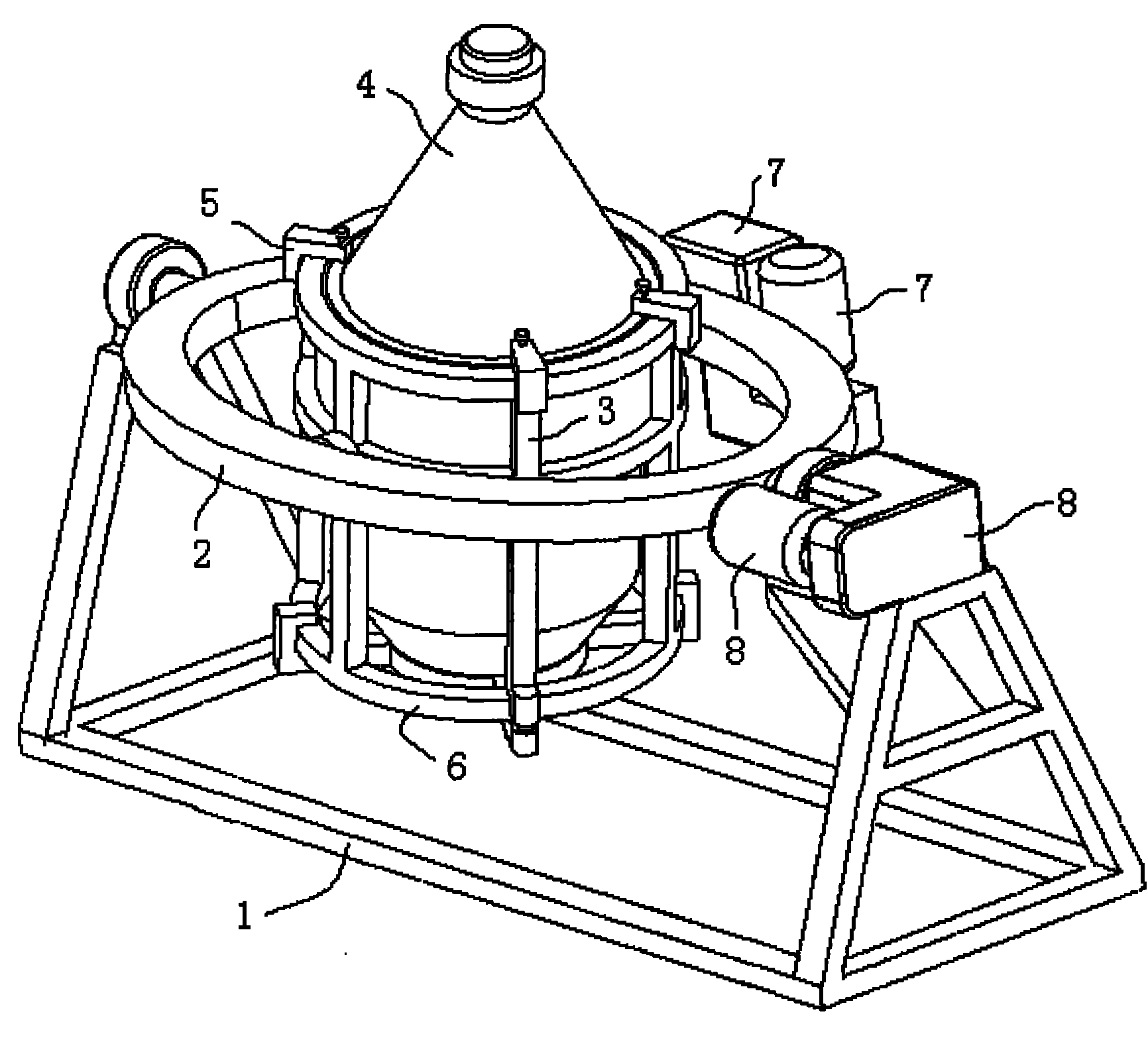

[0012] The specific structure and operation process of the present invention will be described below with reference to the accompanying drawings.

[0013] The three-dimensional mixing machine according to the present invention is mainly composed of: main body support 1; main rotating body 2; auxiliary rotating body 3; mixing tank 4; ; The main rotating body gear box and motor 8 components.

[0014] The connection mode between each part: the main body bracket 1 and the main rotating body 2 are connected by bearings; the main rotating body 2 and the auxiliary rotating body 3 are also connected by bearings; the mixing tank 4 is connected by the upper clamp 5 and the bottom clamp 6 They work together and are fixed on the entire frame, and the upper clamp 5 and the bottom clamp 6 are fixed on the auxiliary rotating body 3 through the pin structure; the auxiliary rotating body reduction box and the motor 7 are fixed on the main rotating body 2, but the deceleration The torque of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com