High-power LED (light-emitting diode) phase-control constant-current drive circuit

A LED drive and LED circuit technology, applied in the direction of electric lamp circuit layout, electric light source, energy-saving control technology, etc., can solve the problems of complex circuits, easy aging of devices, high damage rate, etc., and achieve a high degree of intelligence, novel control strategies, large The effect of development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

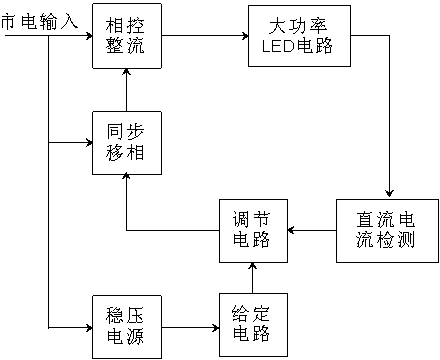

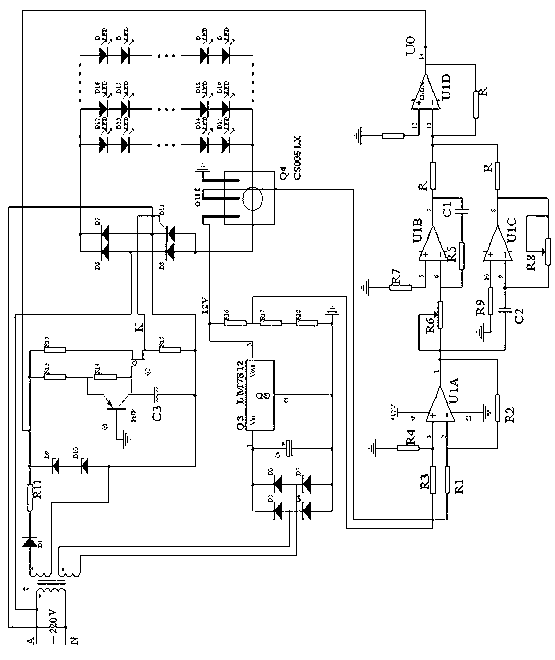

[0011] Such as figure 1 As shown, a phase-controlled constant current high-power LED drive circuit includes a phase-controlled rectification module, a high-power LED circuit module, a synchronous phase-shift module, an adjustment circuit module, a DC current detection module, a regulated power supply module and a given circuit module , which is characterized in that: one way of the mains input is output by the phase-controlled rectifier module to supply power to the high-power LED circuit module, and the other is isolated by the isolation transformer as the synchronization signal of the synchronous phase-shifting circuit and the input of the stabilized power supply, and the DC current detection module detects The output of the high-power LED circuit, its output signal is used as the feedback signal of the regulating circuit, the output of the regulated power supply is connected to the given circuit module, and the output of the given circuit is used as the given signal of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com