Cylinder diameter measurement

A cylinder, measuring machine technology, applied in the direction of mechanical diameter measurement, measuring device, mechanical measuring device, etc., can solve problems such as non-satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

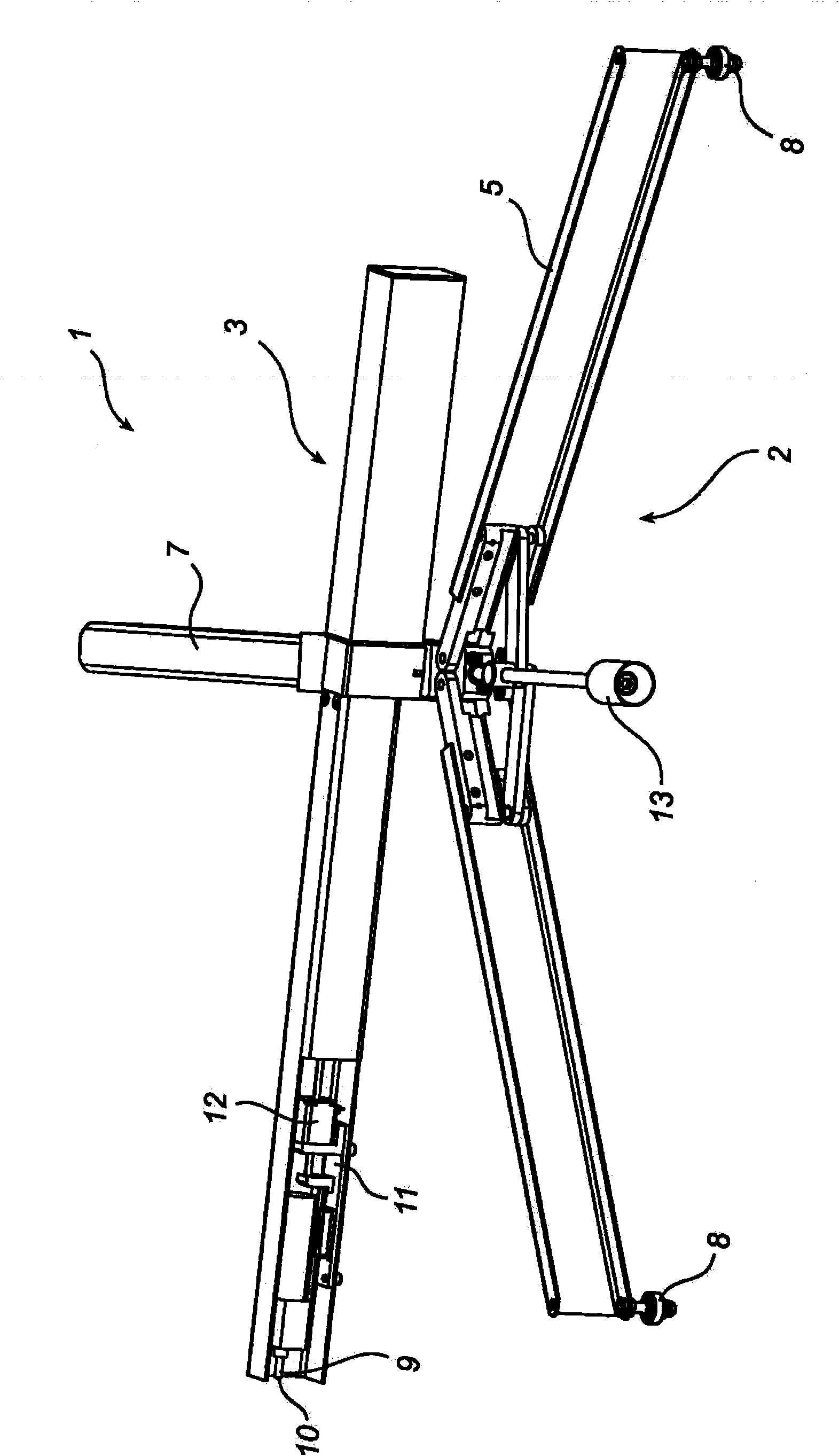

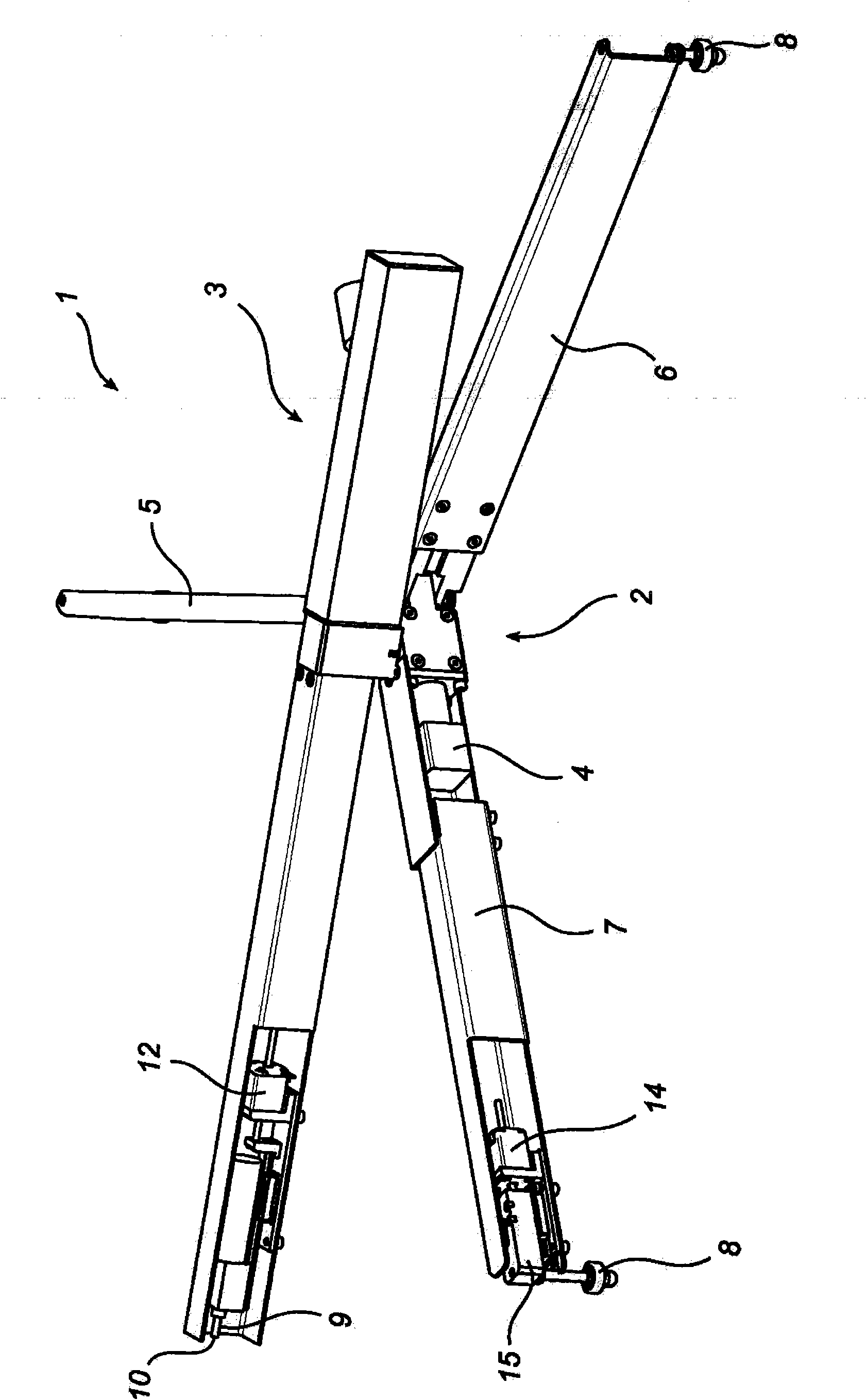

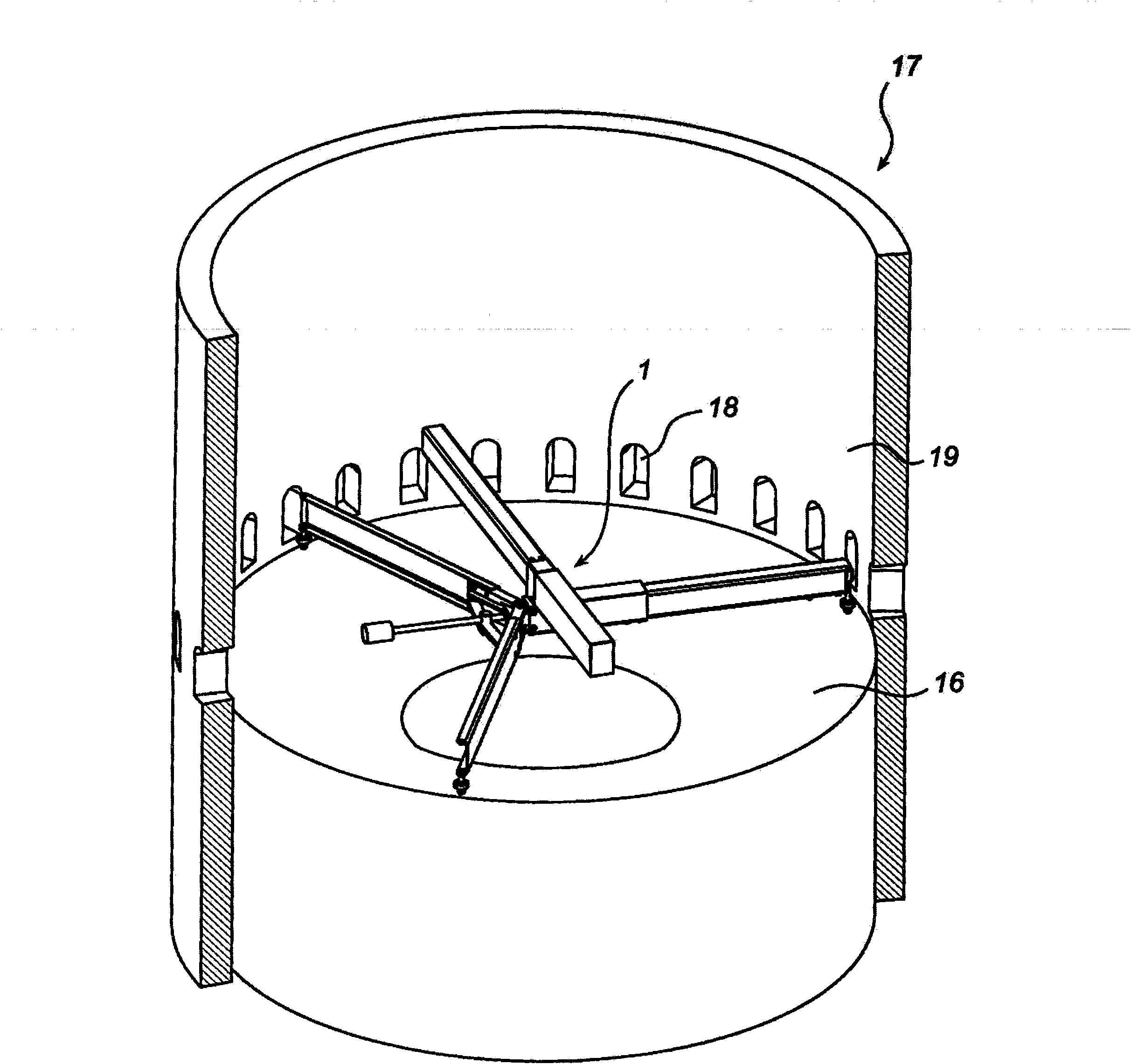

[0046] figure 1 Shown is a measuring device 1 for measuring the diameter of an engine cylinder. The measuring device 1 includes: a measuring frame 2 , a rotatable measuring holder 3 and a rotating motor 4 . The measuring frame 2 and the rotatable measuring holder 3 are detachably connected to each other. The measuring frame 2 has three frame supports 5 , 6 , 7 , wherein the inner ends of the respective frame supports 5 , 6 , 7 are connected to each other. Sliding bearings 8 are mounted on the outer ends of each frame support 5 , 6 , 7 . The rotatable measuring holder 3 is rotatable in a plane perpendicular to the central axis of the cylinder to be measured by the measuring device 1 . The rotatable measuring holder 3 has a probe 9 with a spring tip 10 , a sled 11 and a measuring motor 12 arranged in the measuring holder 3 . The sled 11 and the probe 9 are connected to each other and can be moved substantially radially in said plane relative to the cylinder by means of a mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com