Method and apparatus to suppress vibrations in a rolling mill

A technology for rolling equipment and vibration suppression, which is applied in the direction of rolling mill control devices, metal rolling, vibration control, etc., can solve problems such as high energy content, unstable vibration state, etc., and achieve the effect of reducing phase drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

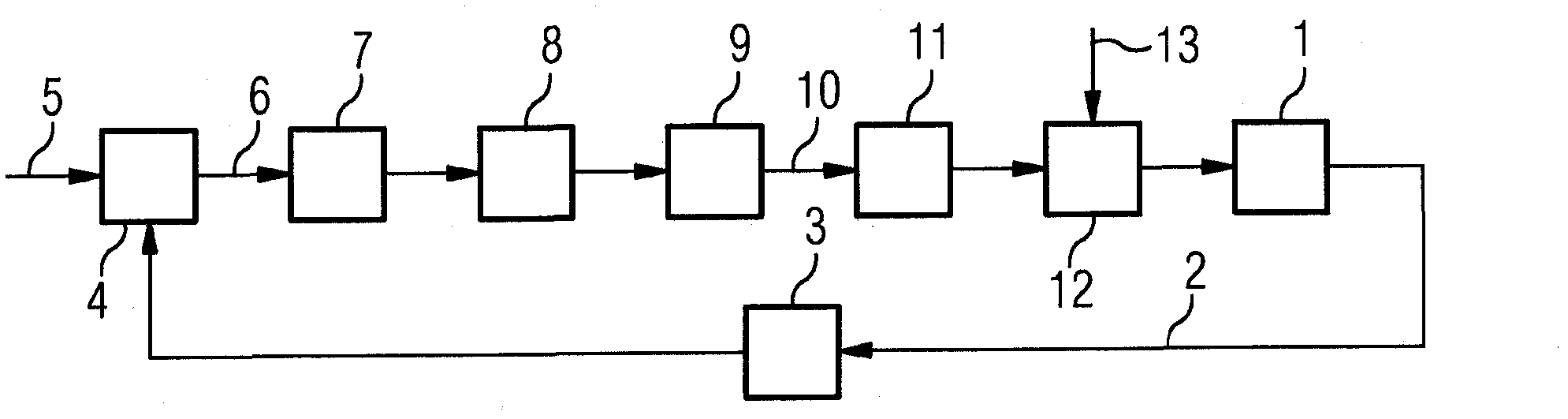

[0034] figure 1 The basic structure of the adjustment object for damping vibrations is shown. The measured variable 2 is supplied via the acceleration sensor 1 connected to the rolls of the rolling stand 12 to a bandpass filter 3 designed as a fourth-order bandpass, which then passes the measured variable, ie The frequency portion of the acceleration signal which is relevant for chatter vibrations is supplied to the regulator 4 . This controller 4 contains a control algorithm and a sub-model characterizing the state of the plant, which calculates in real time at least one time-varying control variable 6 taking into account the filtered measured variable 2 and setpoint variable 5 , which Control variable 6 is supplied to lead / lag element 7 and subsequently to non-linear compensating element 8 . The phase of the signal can be changed by means of the lead / lag element 7 in the particular case of using the manipulated variable 6 . Such a change in phase is particularly advantage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com