Mechanical electric excavation mechanism

A mechanical and electric drive technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of difficult control of excavation speed, high precision requirements, complex structure, etc., to reduce maintenance costs, overcome high precision requirements, Effect of reducing arm weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

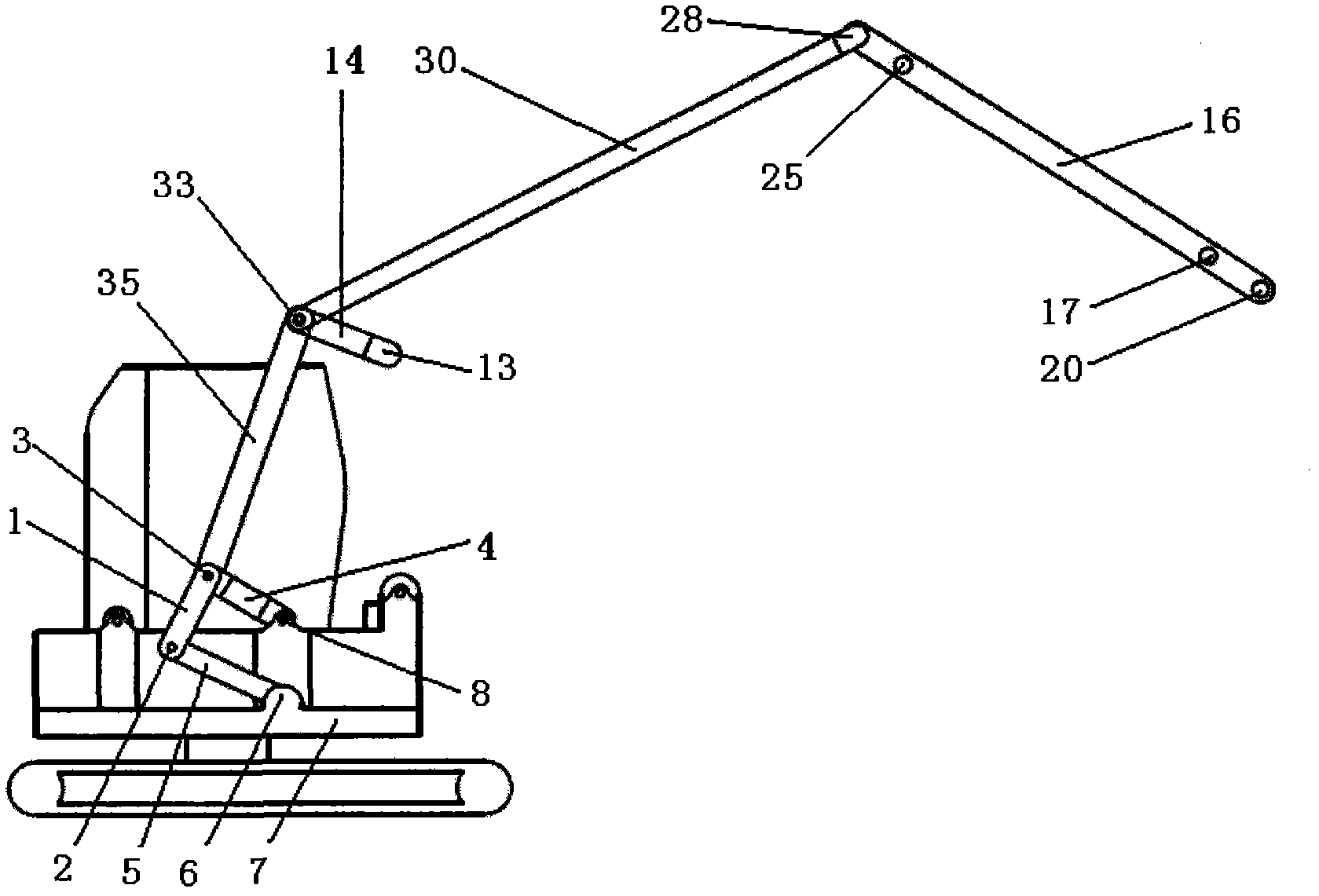

[0022] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

[0023] The mechanical electric excavating mechanism of the present invention includes a boom lifting mechanism, an arm swing mechanism, a bucket reversing mechanism and a frame.

[0024] control figure 1 , figure 2 , the boom lifting mechanism is a planar single-degree-of-freedom controllable mechanism, including a first active rod 10 , a first connecting rod 12 , a boom 15 and a frame 7 . One end of the first active rod 10 is hinged to the frame through the first hinged hole 9 , and the other end is hinged to the first connecting rod 12 through the second hinged hole 11 . The other end of the first connecting rod 12 is hinged to the boom 15 through the third hinge hole 13 . One end of the boom 15 is hinged to the frame 7 through the fourth hinged hole 8 , and the other end is hinged to the arm 16 through the fifth hinged hole 25 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com