High-speed power-assisting balance electronic jacquard machine

A technology of electronic jacquard and force balance, applied in the direction of jacquard machine, textile, textile and paper making, etc., can solve the problems of limiting the production efficiency and failure of high-speed shuttleless jacquard looms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

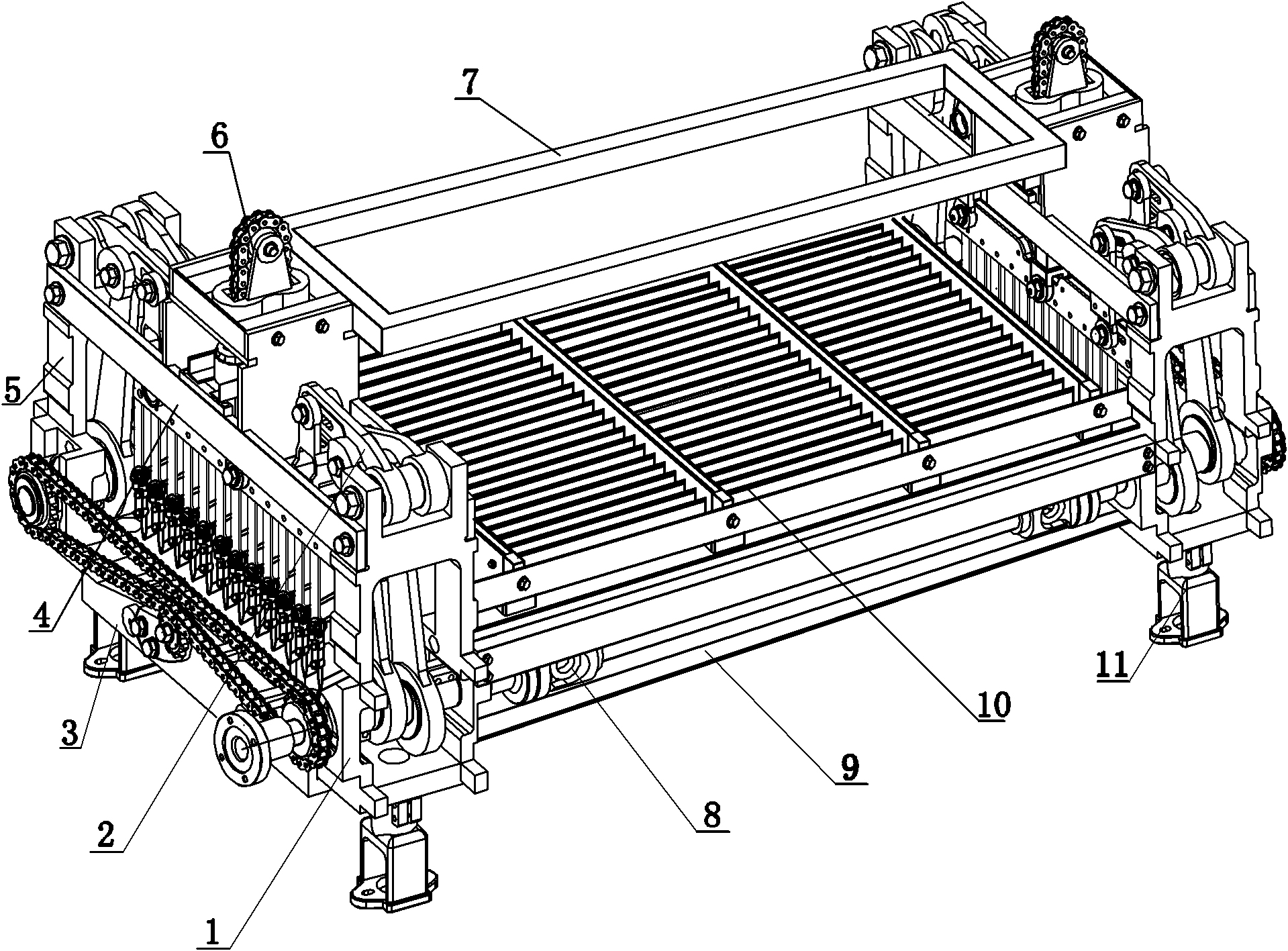

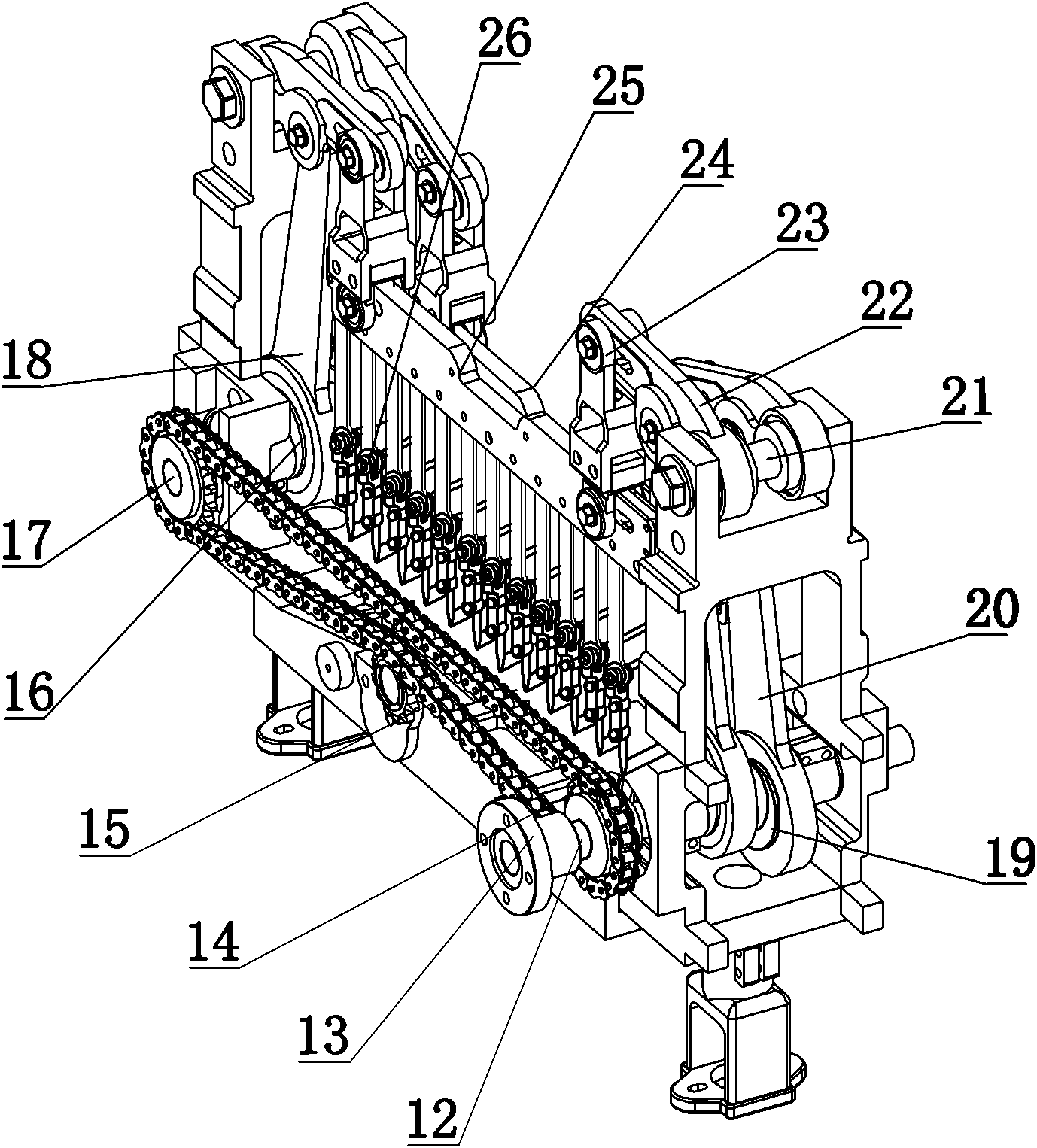

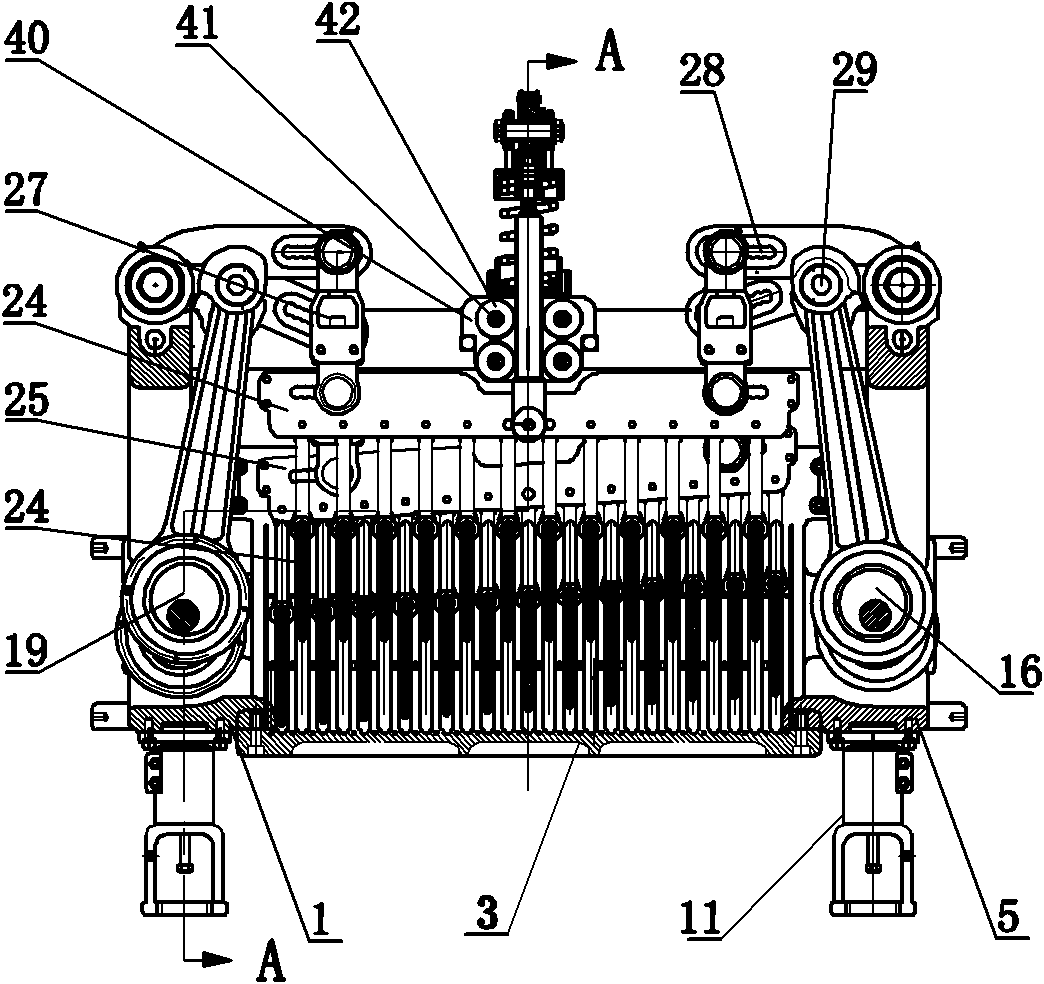

[0025] Such as figure 1 with 2 As shown, a high-speed power-assisted balance electronic jacquard machine includes a front frame 1 and a rear frame 5, and the front frame 1 and the rear frame 5 are fixedly connected by a bottom plate 3 and steel beam plates 4 on both sides. The frame 1 and the rear frame 5 are respectively provided with two sets of eccentric wheel rocker lifting mechanisms 2, and a set is respectively provided between the front frame 1 and the rear frame 5 for the inner lifting frame 24 and the outer lifting frame. 25. Lifting booster buffer mechanism 6 for increasing power and reducing load, a fan frame 7 is connected between the steel beam plates 4 provided on the frames on both sides, and a set of selection box 10 is arranged between the front frame 1 and the rear frame 5 , the bottom of the body is provided with four height adjustment devices 11, the left front frame 1 eccentric wheel rocker lifting mechanism 2 is connected with the right symmetric eccentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com