Circulated stable foams

A technology for stabilizing foam and stabilizer, applied in the foam field, can solve the problems of poor economy and applicability, environmental pollution, non-recyclable foam, etc., and achieve the effects of reducing operating costs, reducing environmental pollution, and strong oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention discloses a recyclable stable foam, which is composed of a base liquid and an antifoaming agent, wherein: the base liquid includes: 0.5-1.5 parts of a foaming agent, 0.1-0.3 parts of a stabilizer, 6- 8 parts of inhibitor, 1-3 parts of wetting reversal agent and 100 parts of water; the defoamer is silicone oil emulsion type defoamer, and the volume percentage of defoamer and base liquid is 0.066-0.068%. In this scheme, said foaming agent, stabilizer, inhibitor, wetting reversal agent and defoamer can adopt the existing products of various models common in the art, and the preparation method can adopt the existing products in the art. Conventional preparation methods in the art.

Embodiment 2

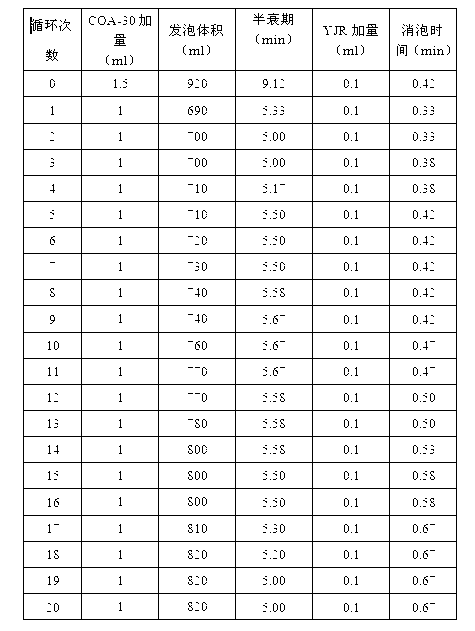

[0029] As a comparatively best embodiment of the present invention, adopt following scheme to have best effect through following test:

[0030] The base liquid includes in parts by weight: 1 part of foaming agent, 0.2 part of stabilizer, 7 parts of inhibitor, 2 parts of wetting reversal agent and 100 parts of water; the defoamer is silicone oil emulsion type defoamer The volume percentage of foaming agent, defoamer and base fluid is 0.067%. The silicone oil emulsion type defoamer refers to the organic emulsion silicon of the commercially available model YJR. Described foaming agent refers to the foaming agent that commercially available model is COA-30. Described stabilizer refers to sodium carboxymethylcellulose CMC. Described inhibitor refers to potassium chloride KCl. The described wetting reversal agent refers to a commercially available model of wetting reversal agent WD-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com