Turning dumper of smoke box

A technology of refilling machine and smoke box, which is used in packaging, liquid handling, emptying containers, etc., can solve the problem that the equipment cannot be installed in place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

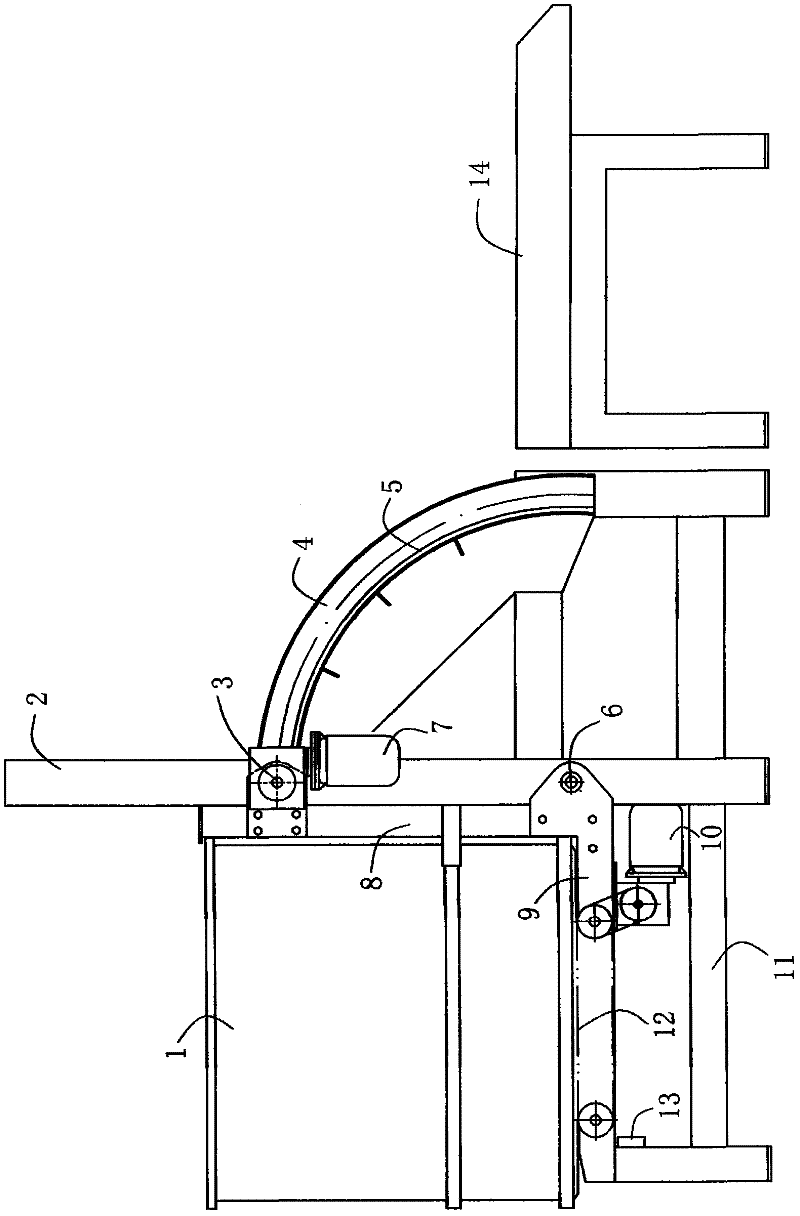

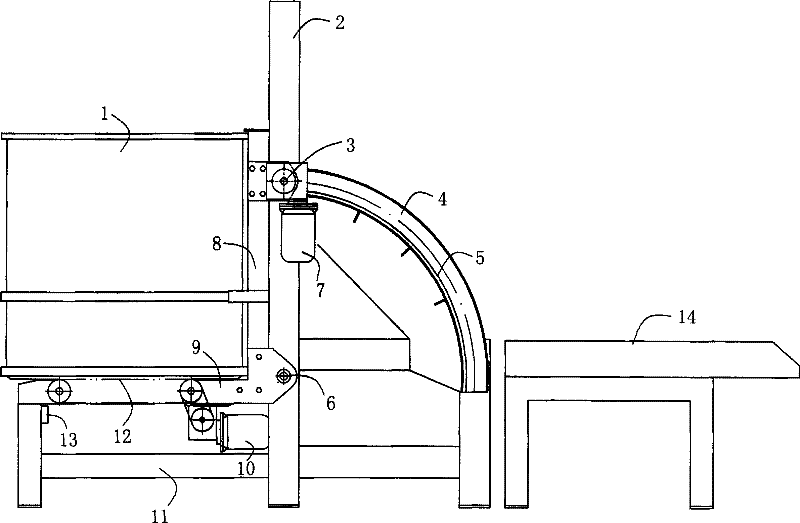

[0014] As shown in the accompanying drawings, the cigarette box turning and unloading machine includes a frame, and the frame includes a cigarette box inlet and outlet frame 11 and a cigarette box turning frame 2 arranged in sequence; a cigarette box holder for receiving the cigarette box 1 frame, the smoke box bracket includes a fixedly connected cross arm 9 and a vertical arm 8, the connection between the cross arm 9 and the vertical arm 8 of the smoke box bracket runs through a turning shaft 6, and the turning shaft 6 is installed on the The lower part of the cigarette box overturn frame 2; the cigarette box in and out drive device, the cigarette box in and out drive device is arranged on the said cigarette box in and out frame 11, and is used to send the cigarette box filled with shredded tobacco into the cigarette box Bracket and the empty smoke box after turning over the box and dumping and resetting are sent out of the smoke box bracket; the turning guide rail 4 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com