Flat wagon center sill

A flat car and draw beam technology, which is applied to railway car body components, chassis, transportation and packaging, etc., can solve the problems of unreasonable stress distribution of draw beams, difficult manufacturing process, low fatigue life level, etc., and achieve improved stress Distributed state, ease of mass production, and the effect of improving the fatigue life level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

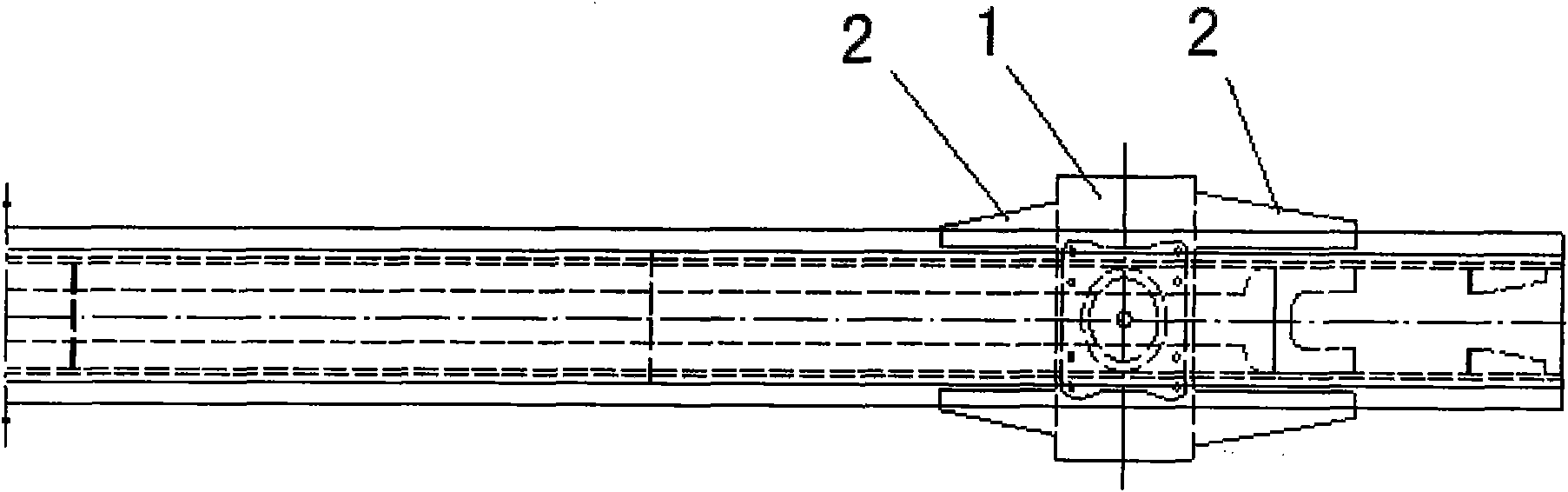

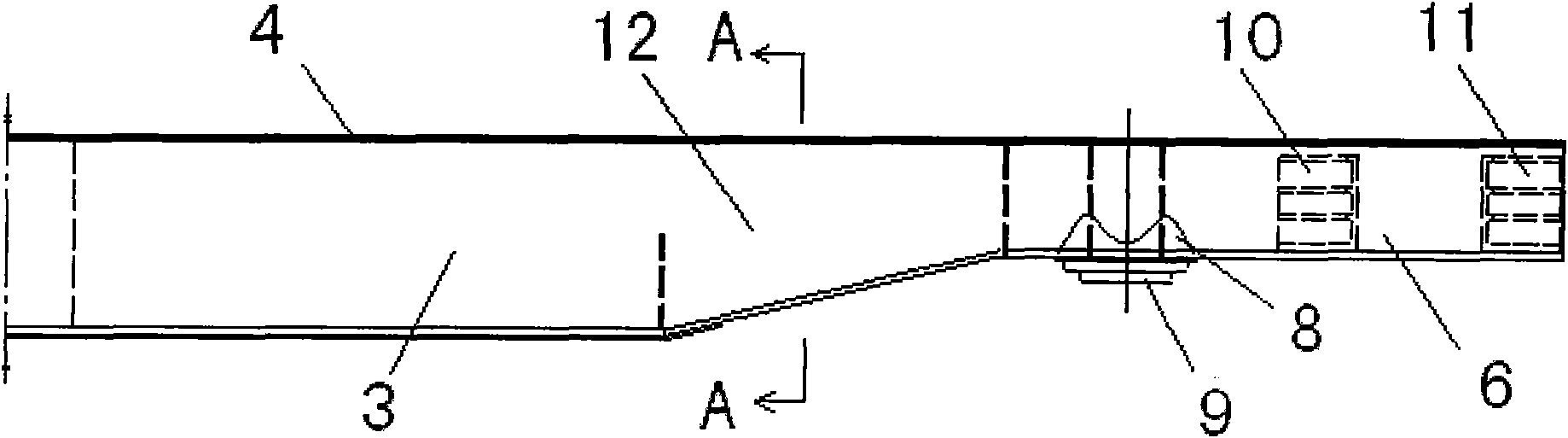

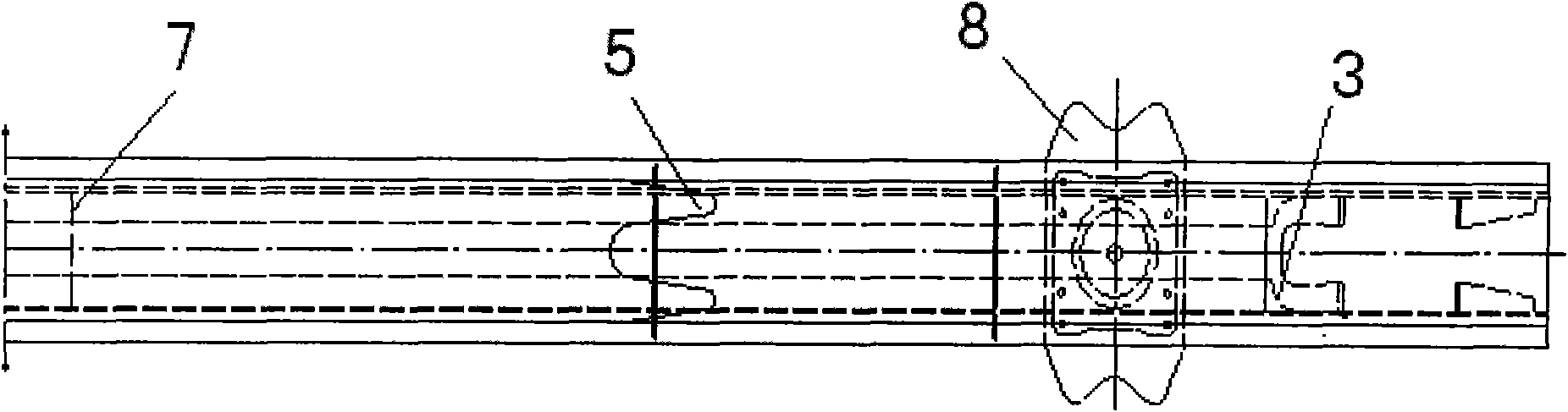

[0016] Such as Figure 2 ~ Figure 4 As shown, the present invention includes two support plates 3, a continuous upper cover plate 4 and a dovetail-shaped lower cover plate 5, and the upper cover plate 4 and the lower cover plate 5 are respectively welded on the upper and lower ends of the two support plates 3. On the lower end face, a box body is formed, and the two ends of the box body form two draw beams 6 of the middle beam of the flat car of the present invention. In the box body, several inner partitions 7 are welded between the upper cover plate 4 and the lower cover plate 5 to divide the box body into several small boxes, thereby enhancing the force strength coefficient of the middle beam of the flat car of the present invention. At the center disk installation place of each draw beam 6, a butterfly connecting plate 8 is assembled and welded s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com