Linear actuator, in particular for adjusting the flaps in motor vehicle turbochargers

A servo drive, linear motion technology, applied in electromechanical devices, machines/engines, mechanical equipment, etc., can solve problems such as hindering the economical utilization of toothed magnetic pole motors under high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

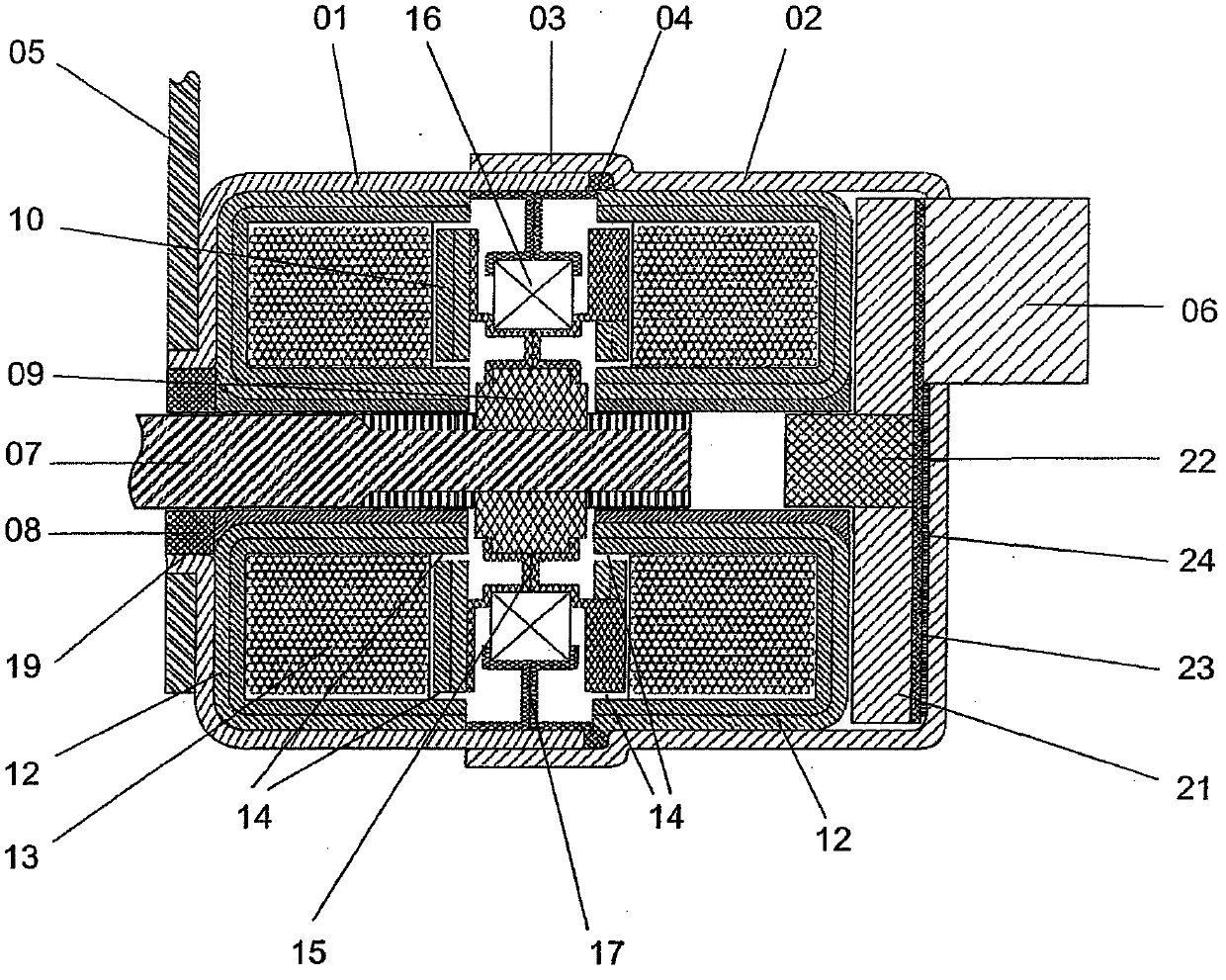

[0030] figure 1 A first embodiment of the linear actuating drive according to the invention is shown in longitudinal section. The linear actuating drive according to the invention comprises a pot-shaped housing formed from a first housing pot part 01 and a second housing pot part 02 . At its open end, the second housing pot 02 has an extension 03 within which the open end of the first housing pot 01 is arranged. For sealing, an O-ring 04 arranged on the first housing pot 01 is used. The first housing pot 01 has a holder 05 for fastening at a connection component. A plug 06 for power supply and signal transmission is arranged on the second housing pot 02 . In modified embodiments, the two housing pots can be connected to each other in different ways. Likewise, the position of the plug is variable.

[0031] Arranged inside the housing is a spindle 07 , one end of which protrudes from the first housing pot 01 . The spindle end can be connected to an element (not shown) to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com