Temperature controller assembly structure and temperature controller using same

A technology for assembling structure and thermostat, applied in the direction of thermal switch parts, etc., can solve the problems that the conductive column 05 cannot be pre-installed, it is difficult to ensure the qualified rate of assembly quality, and the automation of product assembly cannot be realized, so as to achieve stable structure and production. High efficiency and large overcurrent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

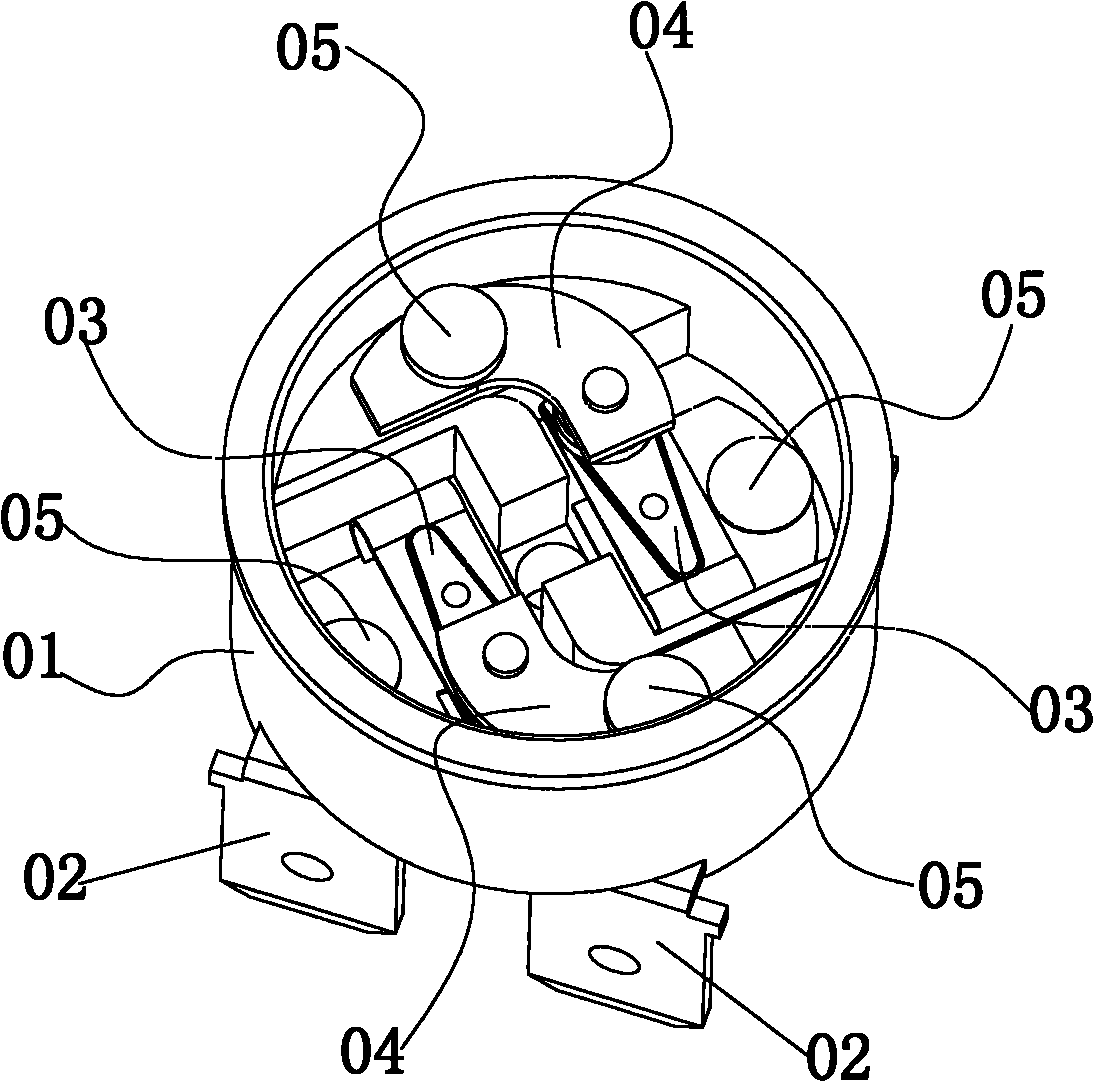

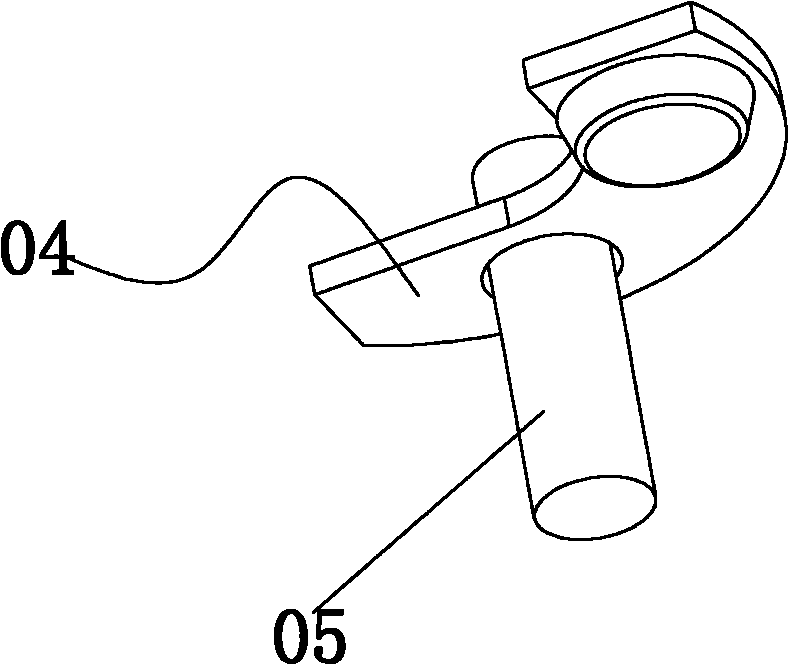

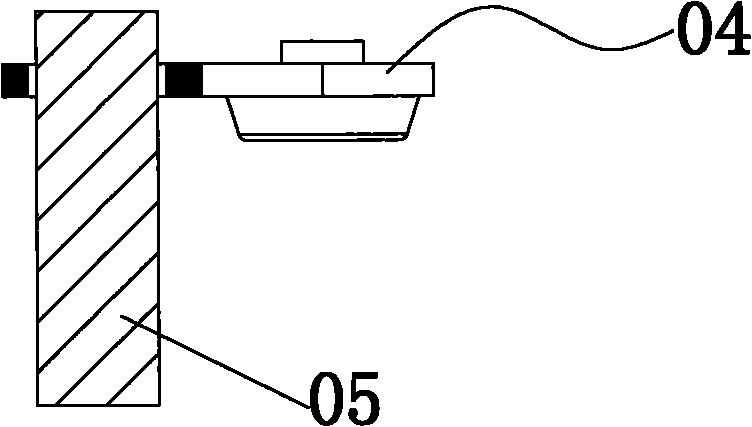

[0037] like Figure 6 to Figure 15 As shown, a thermostat assembly structure includes a base 1, two pairs of power terminals arranged at the bottom of the base 1, and two movable contact pieces and two static contact pieces arranged in the base 1. The said The power terminal includes a first power input terminal 21 , a first power output terminal 22 , a second power input terminal 23 and a second power output terminal 24 , and the moving contact piece includes a first moving contact piece 31 and a second moving contact piece 32 , the static contact piece includes a first static contact piece 41 and a second static contact piece 42, wherein, the first movable contact piece 31 is connected with the first power input terminal 21 by riveting to achieve electrical connection after interference fit with the screw 5, The first static contact piece 41 is riveted to the first power output terminal 22 after interference fit with the screw 5 to realize electrical connection, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com