High-order temperature compensation complementary superposition-based high-precision band-gap reference circuit

A high-order temperature compensation and reference circuit technology, applied in the direction of adjusting electrical variables, control/regulation systems, instruments, etc., can solve problems such as increased process sensitivity, increased impact on circuit performance, and increased difficulty, achieving high process stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

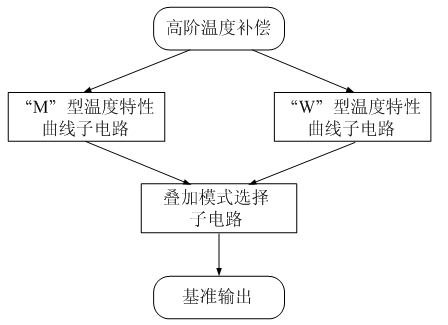

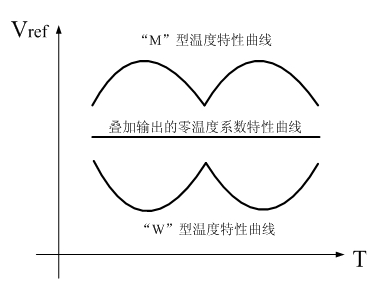

[0016] Such as figure 1 As shown, the present invention is based on a high-precision bandgap reference circuit based on high-order temperature compensation complementary superposition, including "M" type and "W" type temperature characteristic curve subcircuits and superposition mode selection subcircuits, "M" type and "W" type The temperature characteristic curve sub-circuits are complementary and symmetrical, and the "M" and "W" temperature characteristic curve sub-circuits include a feedback control circuit, a current generation circuit and an output circuit. The input end of the sub-circuit and the output end of the output circuit are connected in series with the feedback control circuit and then connected with the input end of the current generation circuit.

[0017] Such as image 3 As shown, the circuit of the present invention includes two sub-circuits for generating complementary temperature characteristic curves and one sub-circuit for superposition selection mode. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com