Device for testing dynamic characteristic parameters of fixed joint surface and testing method thereof

A technology for fixing the joint surface and dynamic characteristics, which is applied in vibration testing, measuring devices, and testing of machine/structural components, etc. It can solve the problem that the normal and tangential dynamic characteristic parameters of the same joint surface cannot be compared, and the mode shape is not considered. Whether it conforms to the basic theory, does not eliminate the influence of the box, etc., and achieves the effect of simple structure, eliminating foundation displacement, and avoiding rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

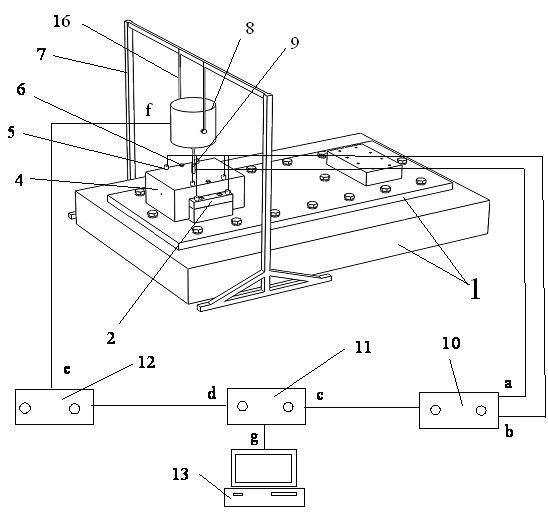

[0028] combine figure 1 , figure 2 , image 3 and Figure 4, a kind of test device of dynamic characteristic parameter of fixed joint surface of the present invention, comprises measurement platform, charge amplifier 10, digital analyzer 11, power amplifier 12, electronic computer 13; Described measurement platform comprises base 1, lower experiment plate 2, Experimental sample 3, upper experimental board 4, several piezoelectric acceleration sensors 5, pressure fastening bolts 6, bracket 7, vibrator 8, impedance head 9 and flexible rope 16, the lower experimental board 2 is fixedly connected to the base 1 The upper and lower experimental plates 2 are provided with an upper experimental plate 4 with a U-shaped structure in which the opening direction is downward. The lower experimental plate 2 is located in the opening of the U-shaped structure of the upper experimental plate 4, and the experimental sample 3 is located between the upper experimental plate 4 and the lower ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com