Six-gear directly selecting structure for automobile speed changer

A technology for automobile transmission and gear selection, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc., and can solve problems such as potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

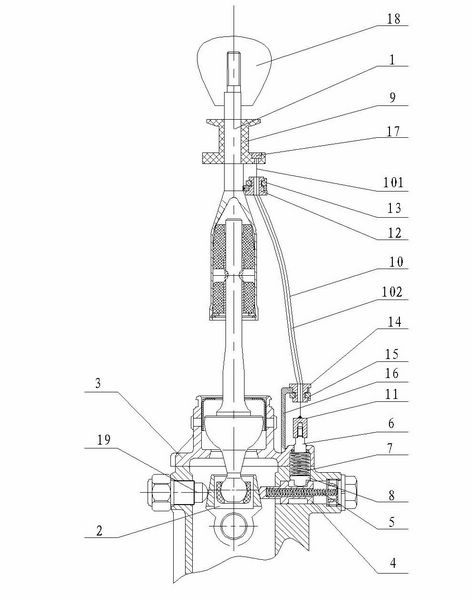

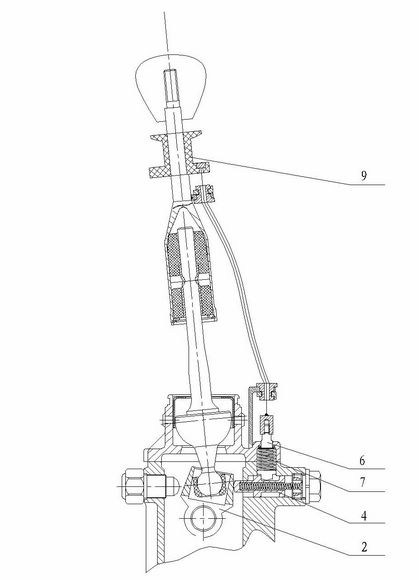

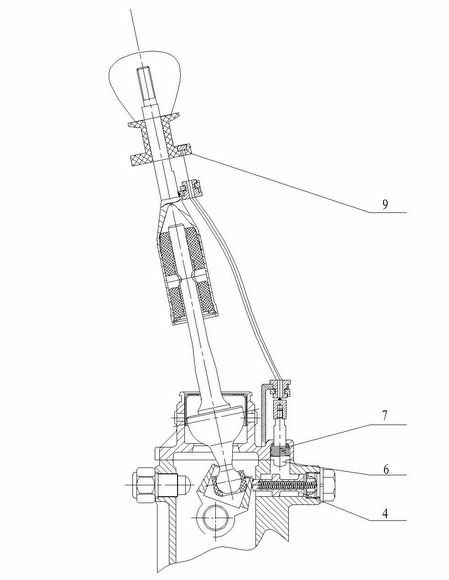

[0022] Depend on figure 1 It can be seen that the gear selection structure of the direct-operated six-speed automobile transmission of the present invention limits the reverse gear of the gear position structure provided by the existing six-speed layout. The reverse gear shown in this embodiment is located at the first and second gear selection The position is on the same side, and the shifting block 2 is selected through the shift lever 1. As shown in the figure, it mainly includes the positioning pin 4 of the first and second gears and the vertical pin 19 of the fifth and sixth gears. This structure is mainly included in the shift dial The first and second gear positioning pins 4 that can slide along the cavity below the control cover 3 under the block 2 are moved, and the elastic elements 5 that are installed in cooperation with the first and second gear positioning pins 4 to return the first and second gear positioning pins 4, and the first and second gear positioning pins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com