Fully prestressed concrete solidly hammered picket-free square pile

A prestressing and concrete technology, applied in the direction of sheet pile walls, structural elements, building components, etc., can solve the problems of affecting construction and easy fracture, and achieve the effect of improving vertical bearing capacity, good construction stability and high end resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

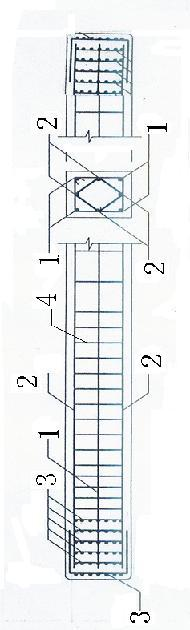

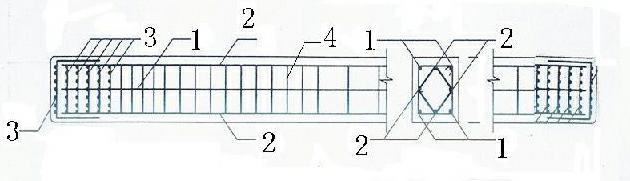

[0013] Such as figure 1 As shown, a fully prestressed concrete solid hammered non-pile point square pile, the fully prestressed concrete solid hammered non-pile point square pile includes a pile body; Stirrups 4 and prestressed main reinforcements 1 and 2 are bound and connected at fixed distances; the ends of fully prestressed concrete solid hammered square piles without pile points are provided with reinforcing ribs 3; fully prestressed concrete solid hammered square piles without pile points Concrete as a whole.

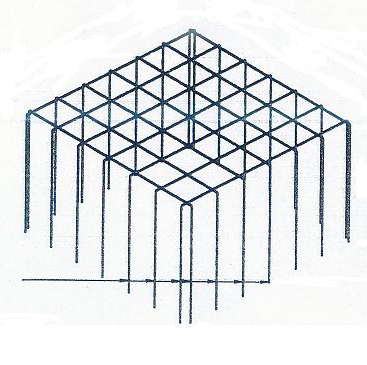

[0014] Such as figure 2 As shown, the reinforcing rib 3 has a hat-shaped structure. The reinforcing rib 3 is bound and connected with the intersection of the prestressed main rib and the spiral stirrup. A steel cap is arranged outside the end of the square pile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com