Film-feeding and film-cutting mechanisms of film packager

A film feeding and film bag technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of reducing production efficiency, film breaking, affecting production efficiency, etc., to save time for changing film rolls and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings of the description.

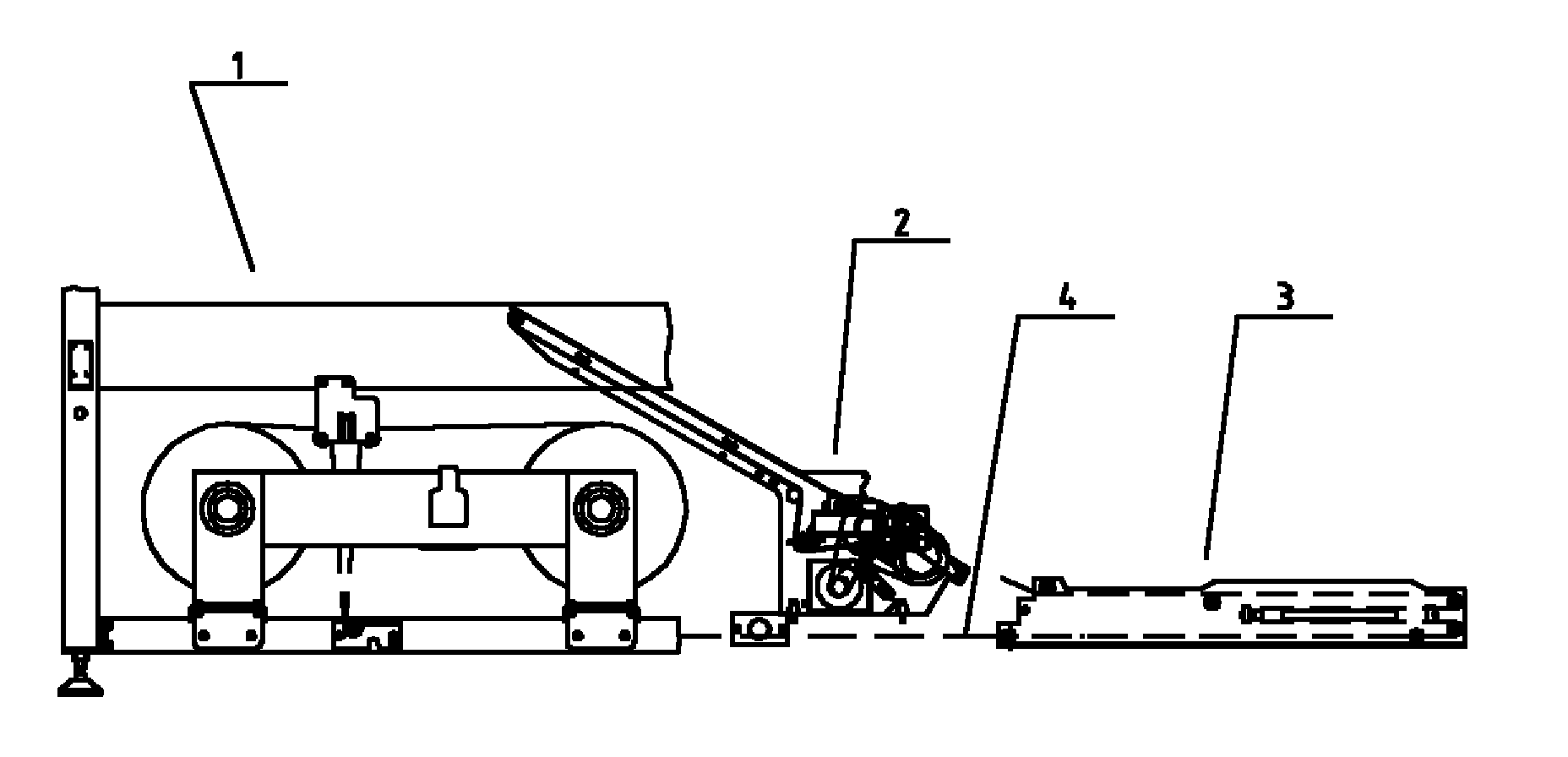

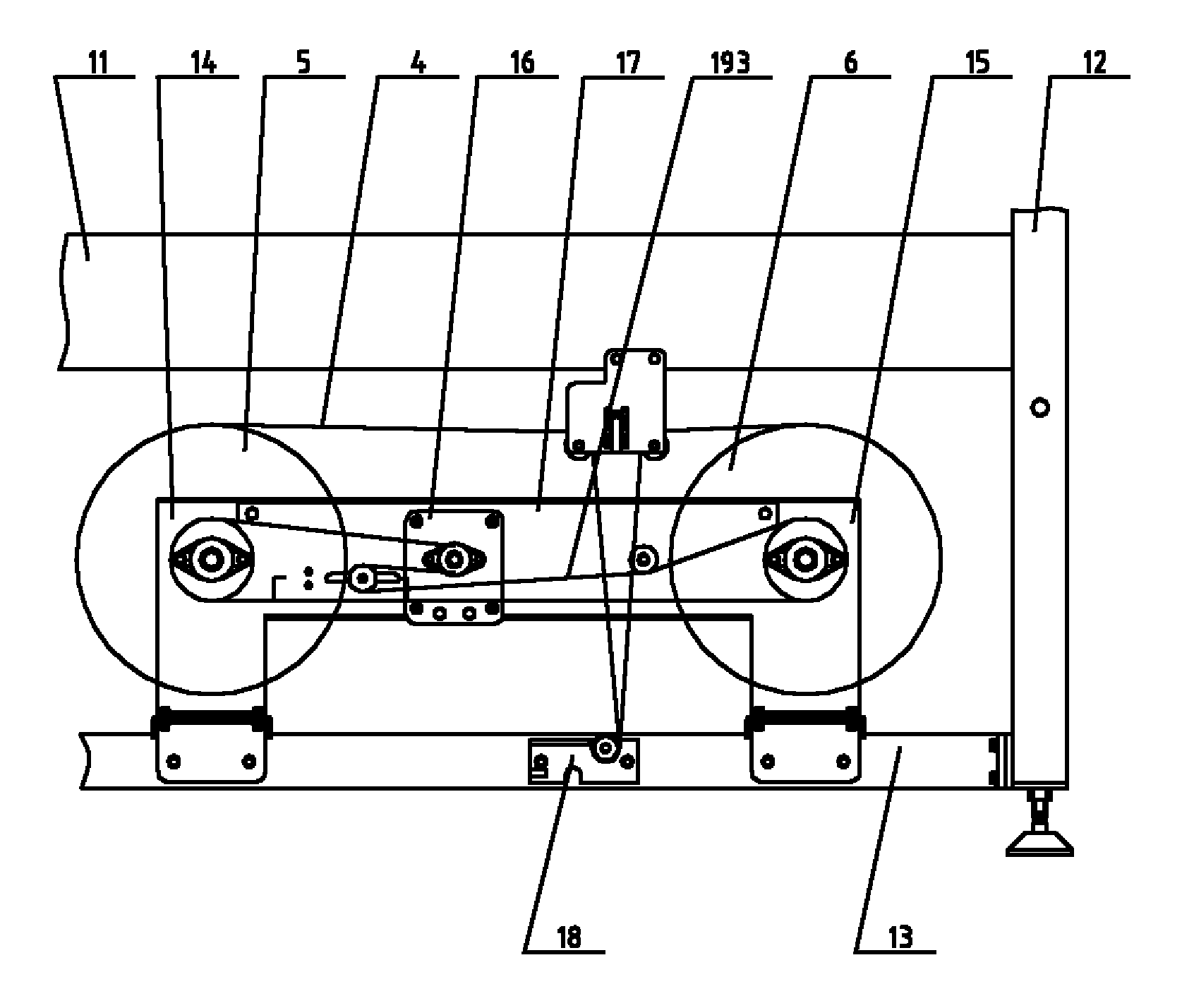

[0036] A film feeding and cutting mechanism for a film packaging machine, which sequentially includes a film roll supporting part 1, a film tensioning part 2, and a film cutting and conveying part 3 according to the material conveying direction.

[0037]Described film roll supporting part 1 comprises the framework that is made of column 12 and crossbeam 11,13, is provided with first film roll supporting seat 14, the second film roll supporting seat 15 on described lower crossbeam 13, the first film roll supporting seat The seat 14 and the second film roll support seat 15 are arranged front and back, with a certain distance between them. The first film roll supporting seat 14 is provided with a first bearing 143, the first bearing 143 is provided with a first rotating shaft 141 for placing the film roll 5, and one end of the first rotating shaft 141 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com