Automobile windscreen wiper

A technology for wipers and automobiles, which is used in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve problems such as affecting the appearance, excessive components at the connection between the flat blade and the scraper arm, and affecting the driver's field of vision. Achieve the effect of strong practicability, improved front vision, and wide field of vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

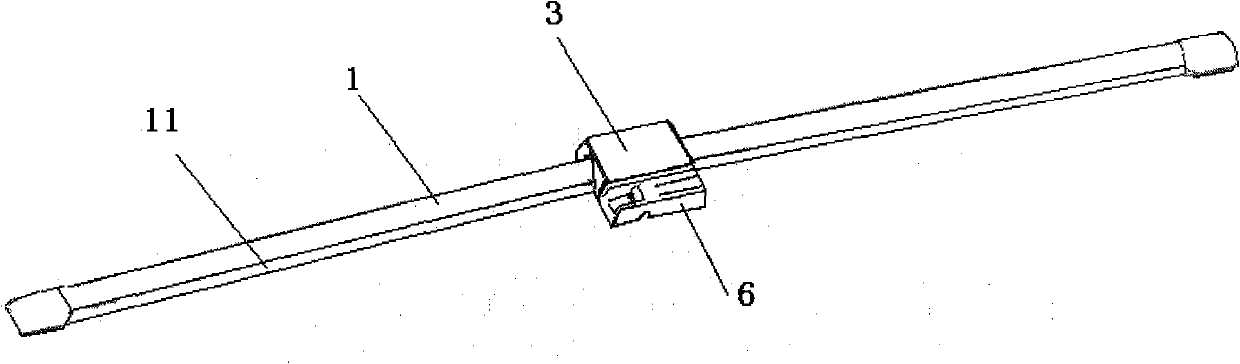

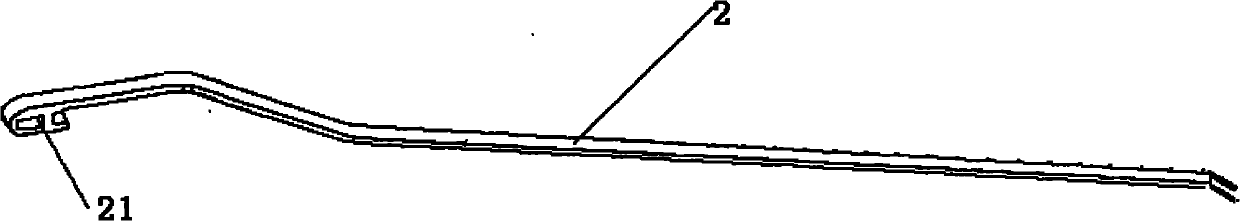

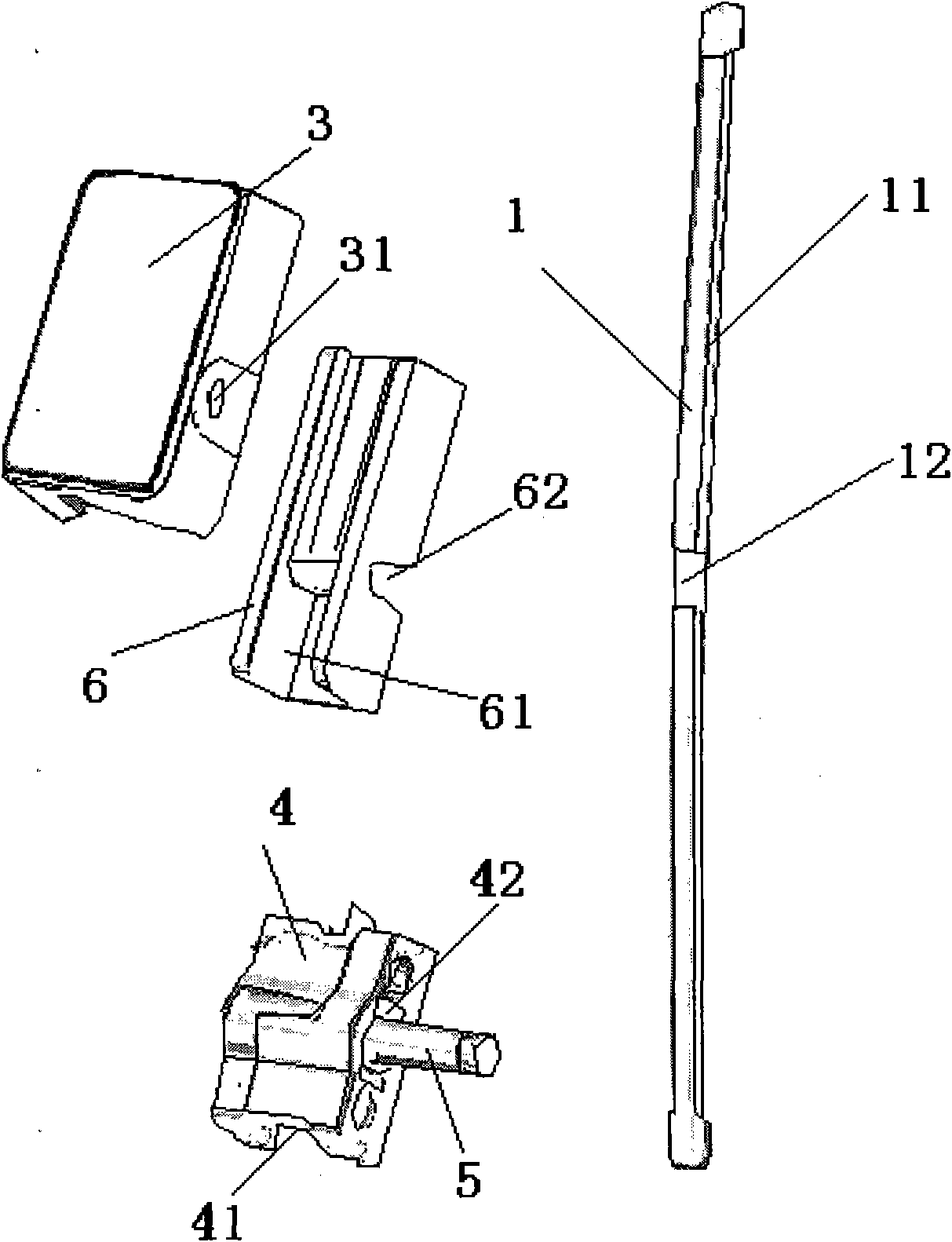

[0021] Combine below Figure 1 to Figure 4 , the present invention is further described:

[0022] A car wiper, comprising a scraper 1 and a scraper rod 2, the scraper 1 is connected with a strip reed 11, the scraper 1 is installed on a metal connector 4, and the scraper 2 is installed on an elastic card 6; the scraper 1 , the metal connector 4, the scraper bar 2 and the elastic card 6 are connected into one piece through a fixed connection device; the overall width of the elastic card 6 and the metal connector 4 after connection is not greater than 20 mm.

[0023] Specifically, the fixed connection device can be a rivet 5, and the first passage hole 21 of the rivet, the third passage hole 41 of the rivet and the fourth passage hole of the rivet are sequentially provided on the scraper bar 2, the metal connector 4 and the elastic card 6. 62. The rivet 5 passes through the first rivet passage hole 21 , the rivet third passage hole 41 and the rivet fourth passage hole 62 sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com