Manipulator of stacker crane

A technology of manipulators and palletizers, which is applied in the direction of manipulators, program-controlled manipulators, ceramic molding machines, etc., can solve the problems of cleaning the surface of brick adobes, etc., and achieve the effects of easy operation and adjustment, improved cleaning effect, and improved clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

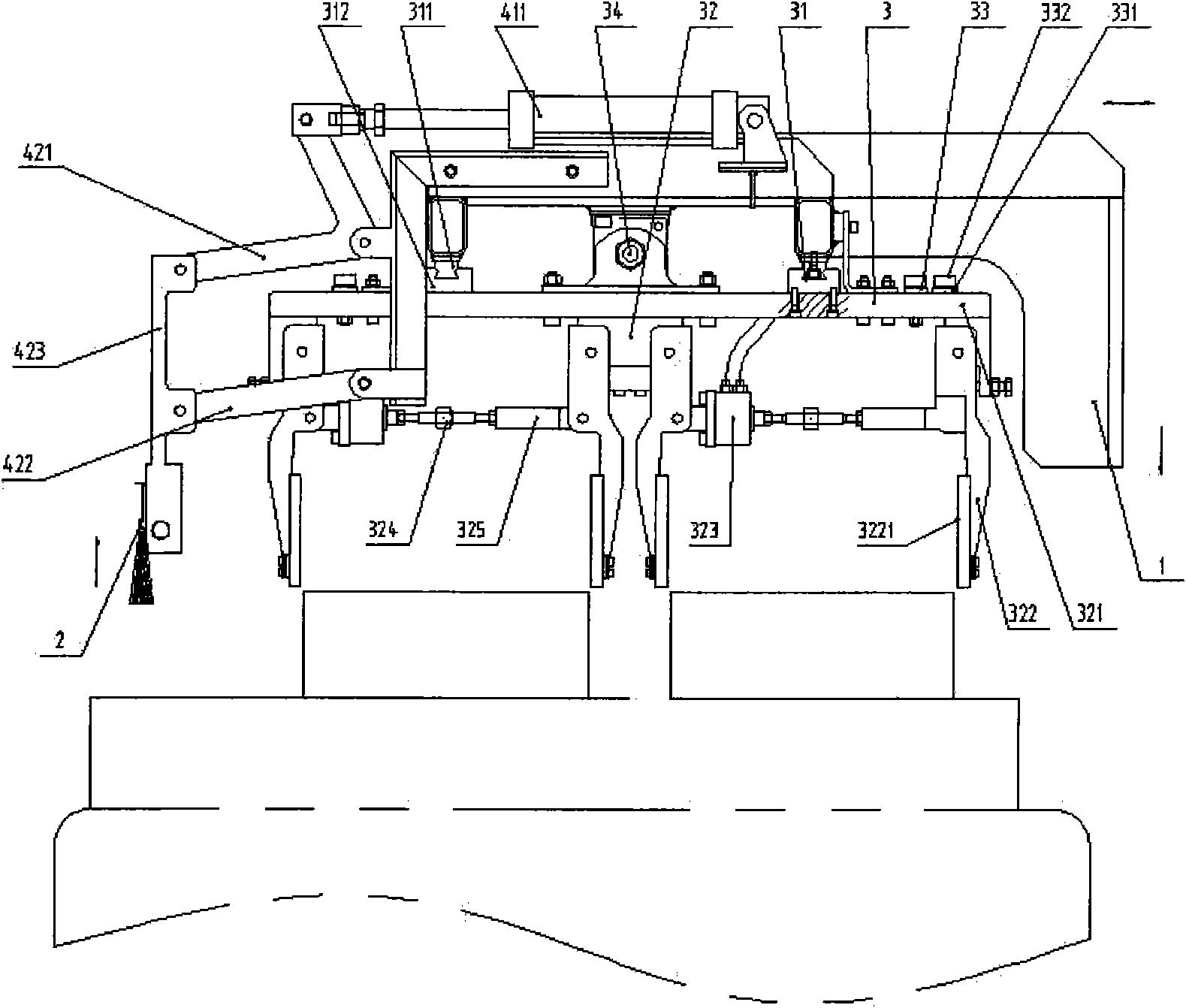

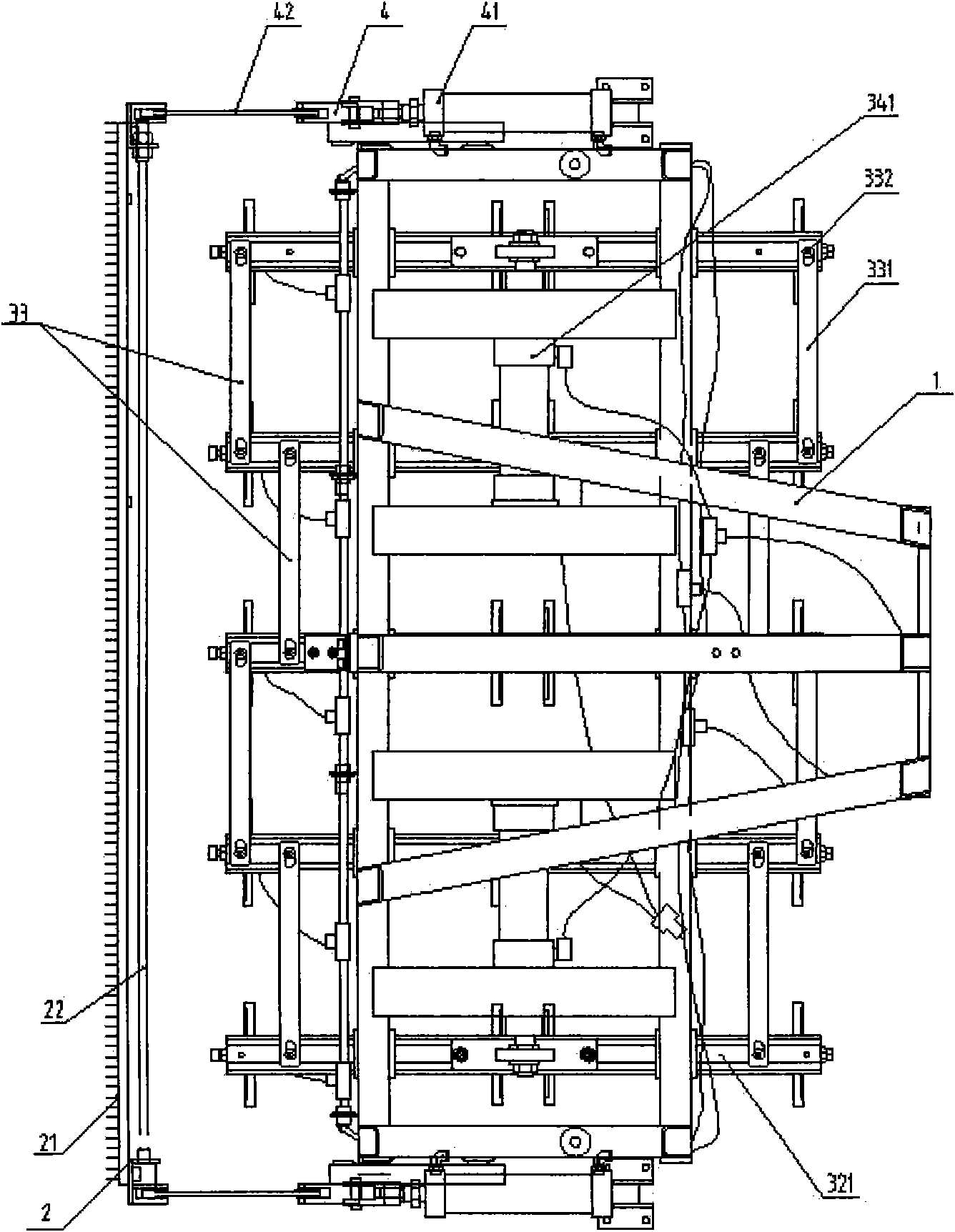

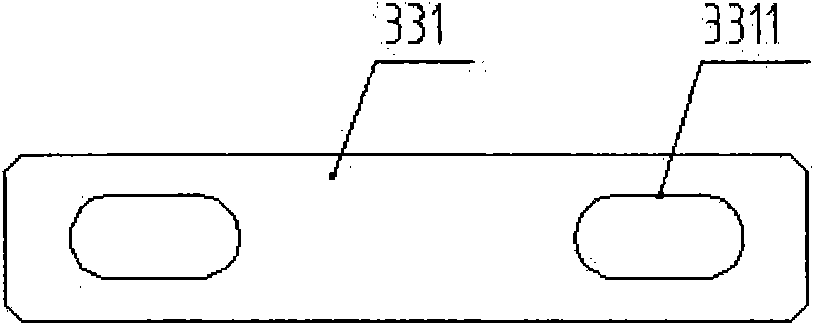

[0019] refer to figure 1 and figure 2 , The manipulator of the palletizer includes a frame 1 , a cleaning mechanism 2 and a clamping mechanism 3 , and the cleaning mechanism 2 has a brush 21 and an air pipe 22 . Also comprise swing lift mechanism 4, swing lift mechanism 4 comprises swing drive mechanism 41 and swing mechanism 42, swing drive mechanism 41 is hinged with swing mechanism 42, swing drive mechanism 41 and swing mechanism 42 are hinged with frame 1 respectively, and cleaning mechanism 2 and swing mechanism 42 are hinged with frame 1 respectively. The swing mechanism 42 is fixedly connected, and the swing drive mechanism 41 drives the swing mechanism 42 to swing up and down, thereby driving the cleaning mechanism 2 to move up and down. When the cleaning mechanism 2 moves to the lower limit position, the lower end surface of the brush 21 is lower than the lower end surface of the clamping unit 32 , when the cleaning mechanism 2 moves to the upper limit position, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com