Hot pot base, preparation method thereof and combined hot pot components

A technology of hot pot bottom material and hot pot, which is applied in the field of hot pot bottom material, which can solve the problems of difficult storage, inconvenient cleaning, and fluctuation of the taste of hot pot bottom material, and achieve the effect of small space occupation and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

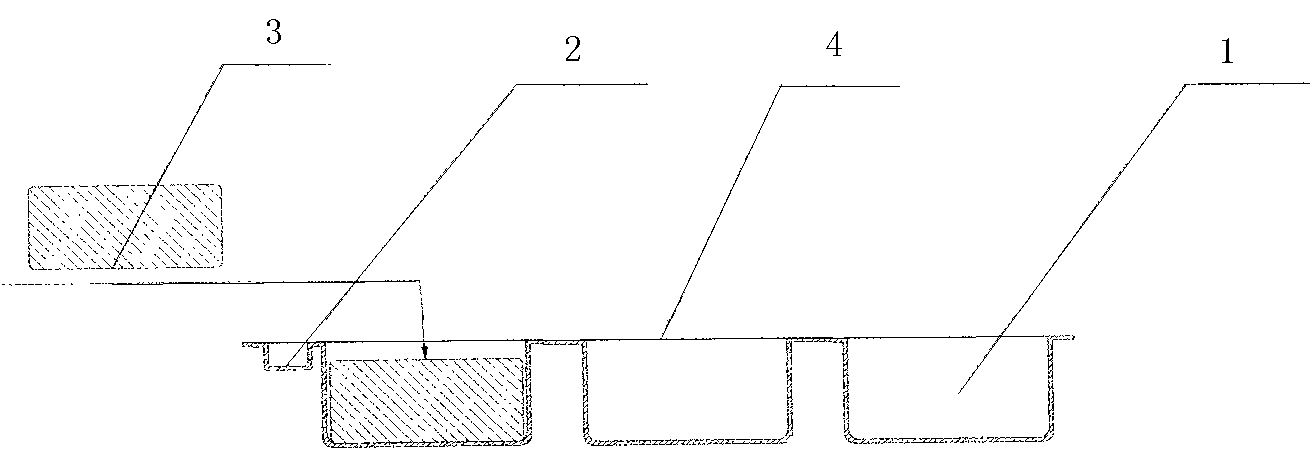

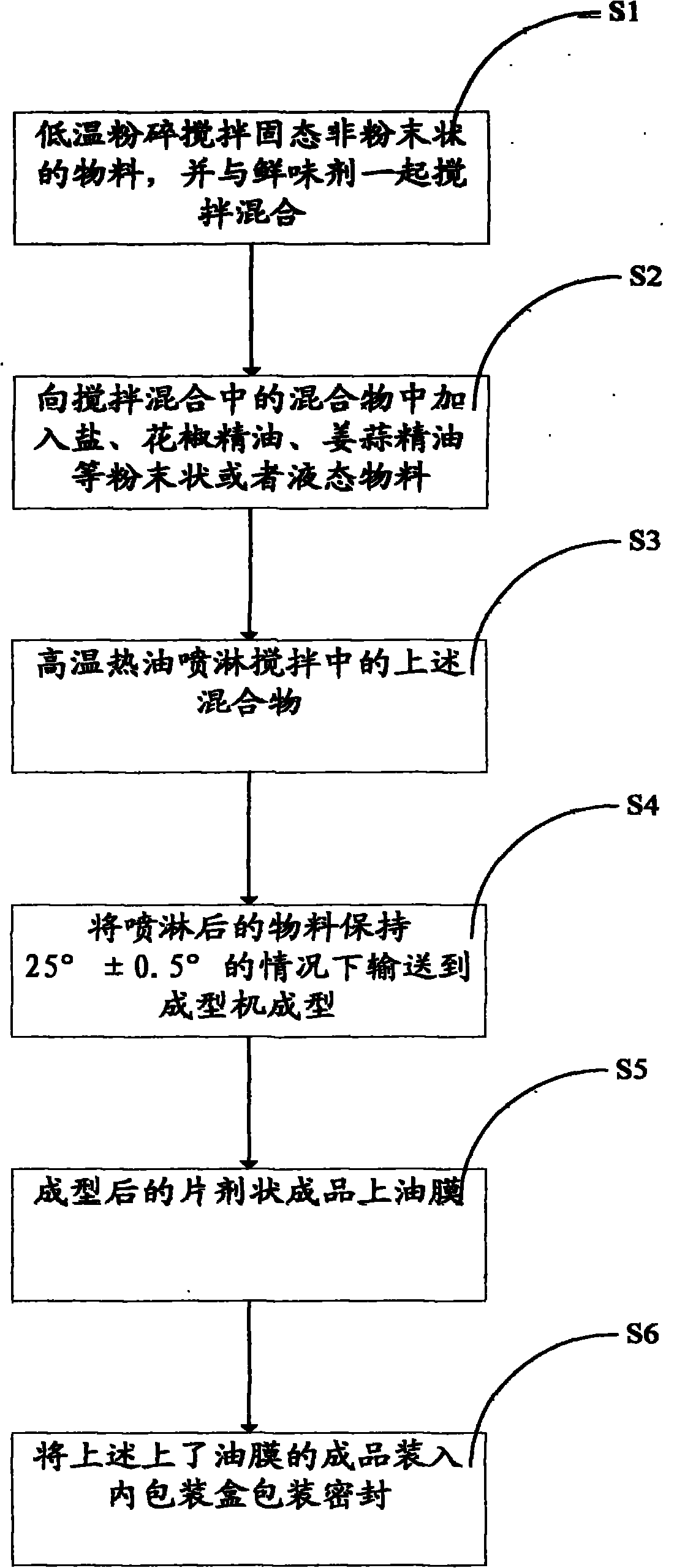

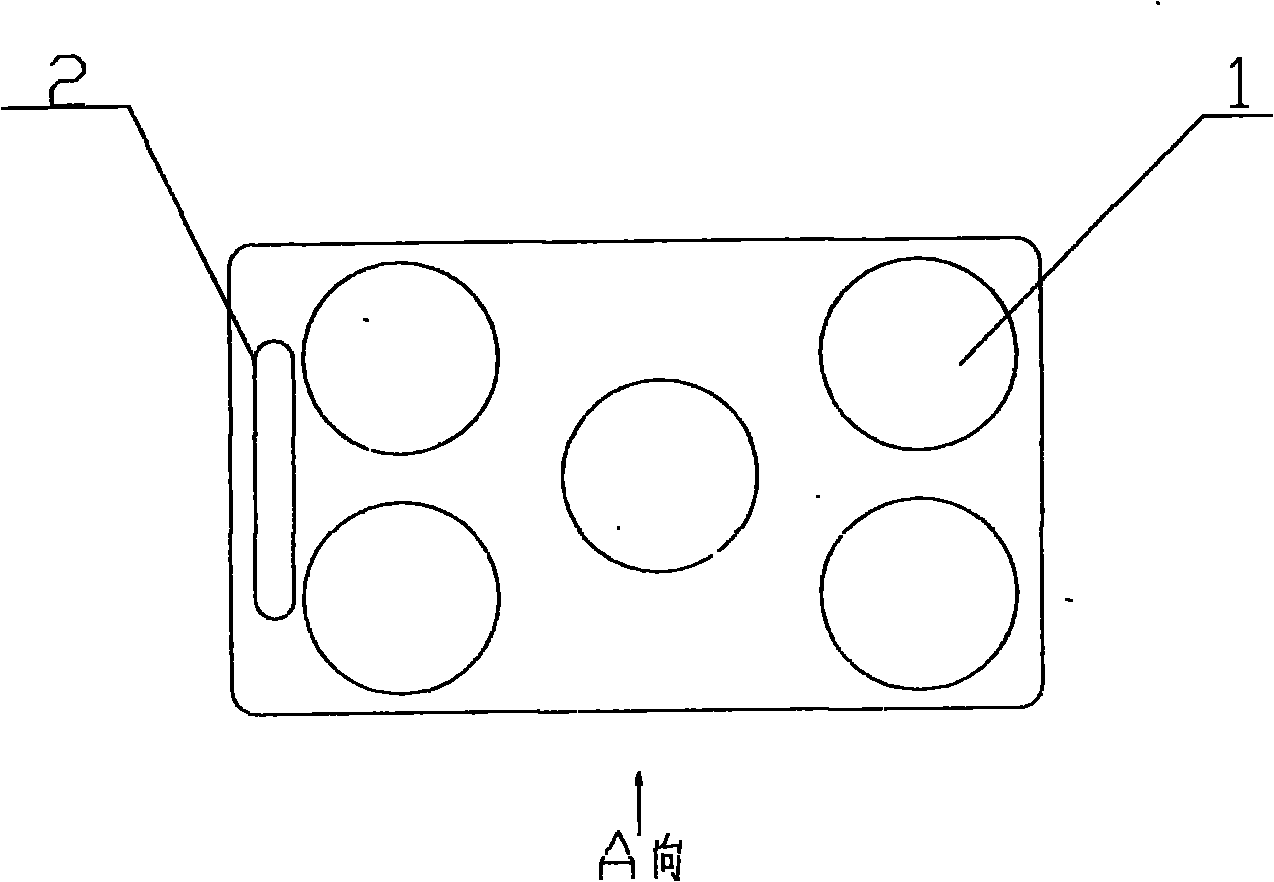

[0057] The first embodiment of the present invention provides a hot pot base material. The hot pot bottom material includes oil, chili, spices, and salt, among which, solid non-powder materials such as pepper and spices are pulverized into powder by a low-temperature pulverization method, and then mixed with other ingredients to form the hot pot bottom material. The proportion of each component needs to be adjusted according to taste. The key is that all solid non-powder materials are pulverized into powder by low-temperature pulverization. According to different requirements, the materials can be pulverized into ultra-fine powders above 300 mesh, or between 200 mesh and 300 mesh. powder.

[0058]The so-called low-temperature pulverization means that the above-mentioned solid non-powder substance is frozen below the embrittlement point, and then pulverized, so that it can be made into powder. The low-temperature crushing technology can not only crush the materials with high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com