Front dielectric paste and preparation method thereof

A medium slurry and slurry technology, applied in the manufacture of ships or lead wires, etc., can solve the problems of poor acid etching, no acid etching, increasing the difficulty of bonding process, etc., and achieve the effect of moderate etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention discloses a method for preparing a pre-medium slurry, including:

[0026] a) Preparation of carrier

[0027] After the acrylic resin and terpineol are evenly mixed, the first filtration is carried out, the mixing ratio of the acrylic resin and the terpineol is 1:4.5-6 by weight, and the carrier is obtained after the first filtration;

[0028] b) Preparation of slurry

[0029] The second filtration is performed after the carrier is mixed with glass powder, and the glass powder includes: 30wt%-40wt% of B 2 o 3 , 40wt% to 50wt% of ZnO and 10wt% to 20wt% of SiO 2 , the mixing ratio of the carrier and the glass powder is 1:1-2 by weight, and the first slurry is obtained after the second filtration;

[0030] c) Vacuum defoaming

[0031] The first slurry is subjected to vacuum defoaming to obtain a pre-medium slurry.

[0032] Step a is the process of preparing the carrier. The reason why the present invention uses acrylic resin as ...

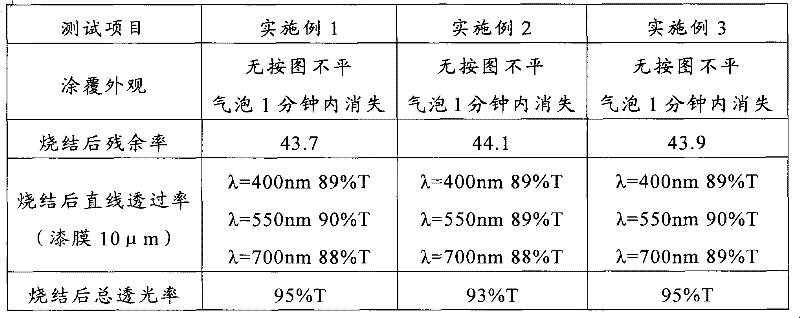

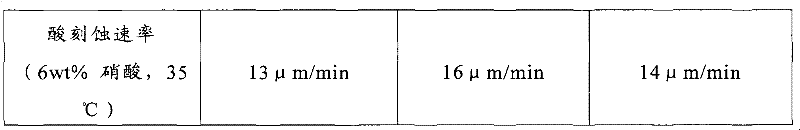

Embodiment 1

[0045] 1. Use acetone to clean the slurry tank at 50°C to 55°C for 2 hours.

[0046] 2. After adding terpineol to the slurry tank, add acrylic resin, wherein the weight ratio of acrylic resin to terpineol is 1:4.928, the total amount of the two is 1000l, and the mixed solution is heated to 120°C and kept for 3min. Fill the slurry tank with nitrogen, then lower the temperature of the mixed liquid in the slurry tank to 70°C, filter the solution in the slurry tank with a filter element with a filtration accuracy of 10 μm, and obtain the carrier after filtration. After testing, the viscosity is 3400mPa·s.

[0047] 3. Add the carrier prepared in step 2 into the mixer, add glass powder and stir for 30 minutes during the stirring process, wherein the glass powder includes: 35wt% B 2 o 3 , 45wt% ZnO and 20wt% SiO 2 , the particle size is 3.0 μm, the weight ratio of the glass powder and the carrier is 1:1.2794, the total amount is 25l, then the slurry is added to the dispersant, the...

Embodiment 2

[0051] 1. Use acetone to clean the slurry tank at 50°C to 55°C for 2 hours.

[0052] 2. After adding terpineol to the slurry tank, add acrylic resin, wherein the weight ratio of acrylic resin to terpineol is 1:4.55, the total amount of the two is 1000l, and the mixed solution is heated to 115°C and kept for 3min. Fill the slurry tank with nitrogen, then lower the temperature of the mixed liquid in the slurry tank to 70°C, filter the solution in the slurry tank with a filter element with a filtration accuracy of 8 μm, and obtain the carrier after filtration. After testing, the viscosity is 3760mPa·s.

[0053] 3. Add the carrier prepared in step 2 into the mixer, add glass powder and stir for 30 minutes during the stirring process, wherein the glass powder includes: 32wt% B 2 o 3 , 48wt% ZnO and 20wt% SiO 2 , the particle size is 2.0 μm, the weight ratio of the glass powder and the carrier is 1:1.1647, the total amount is 25l, then the slurry is added to the dispersant, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com