Diamond lathing cutter track tracing method

A diamond turning and tool path technology, applied in the direction of comprehensive factory control, digital control, electrical program control, etc., can solve the problems of difficult to achieve real-time tracking, large amount of calculation, high dependence, easy application and promotion, and small computing resources. , the effect of high-precision tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

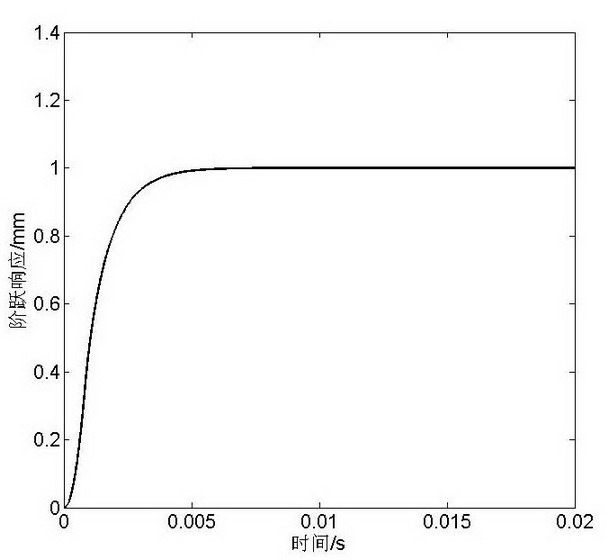

[0044] Example 1. Step Response

[0045] In this example, the trajectory tracking method proposed by the present invention is used to simulate the mechanism model described in formula 9, and the diamond tool trajectory is a step curve with an amplitude of 1 mm. The selected forgetting factor is 0.99, and the unitary operator in operation 3 for:

[0046] (10)

[0047] The tracking effect is attached image 3 As shown, it can be seen from the figure that the response of the tracking method to the step signal has the advantages of no overshoot and fast response time.

example 2

[0048] Example 2. Step tracking

[0049] In this example, the trajectory tracking method proposed by the present invention is used to simulate the mechanism model described in formula 9, and the diamond tool trajectory is a step curve with an amplitude of 0.25 mm. The selected forgetting factor is 0.99, and the unitary operator in operation 3 As shown in formula 10. The tracking effect is attached Figure 4 It can be seen from the figure that the method of the present invention also has a good tracking effect on the step trajectory.

example 3

[0050] Example 3. Sine tracking

[0051] In this example, the trajectory tracking method proposed by the present invention is used to simulate the mechanism model described in formula 9, and the diamond tool trajectory is a sinusoidal curve with an amplitude of 1 mm and a frequency of 200 Hz. The selected forgetting factor is 0.95, and the unitary operator in operation 3 As shown in formula 10. The tracking error curve is attached Figure 5 As shown, it can be seen from the figure that the steady-state tracking error of the method of the present invention for the sinusoidal trajectory is about 0.25%, which can better realize the high-precision tracking of the diamond trajectory.

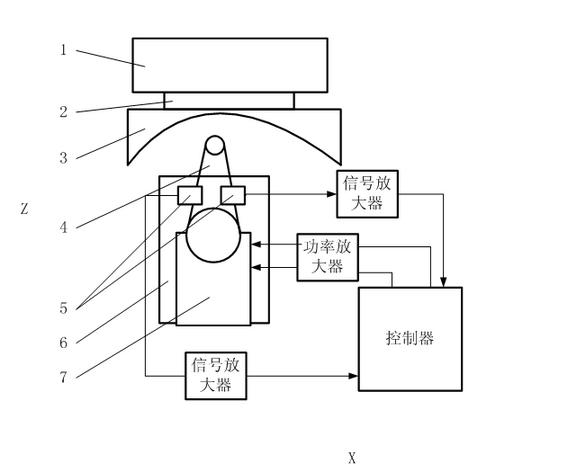

[0052] The system for realizing the method of the present invention is realized through the following technical solutions in specific implementation, combined with the attached figure 1 described as follows:

[0053] The workpiece 3 is clamped on the spindle 1 by the fixture 2 ; the tool 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com