Mechanical guyed automatic transmission clutch execution mechanism

A technology for automatic transmissions and actuators, applied to clutches, mechanical equipment, transmission devices, etc., can solve the problems of many parts in the transmission structure, poor transmission stability, complex transmission structure, etc., and achieve simple structure, precise control, and stable power transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

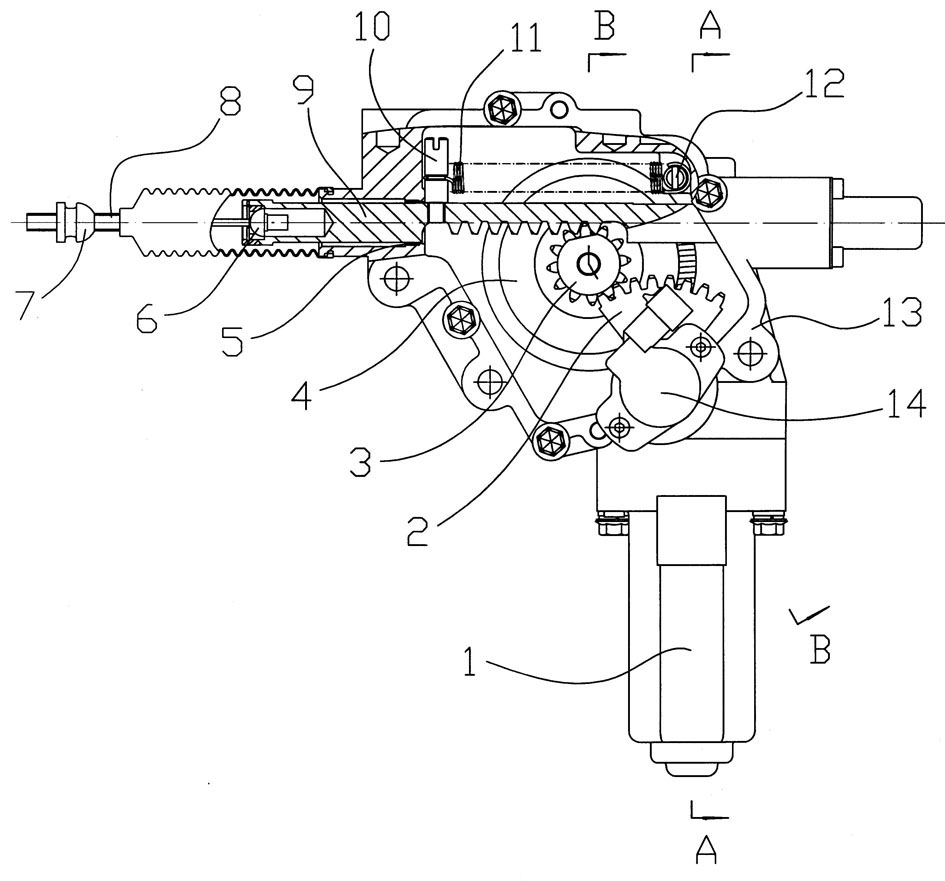

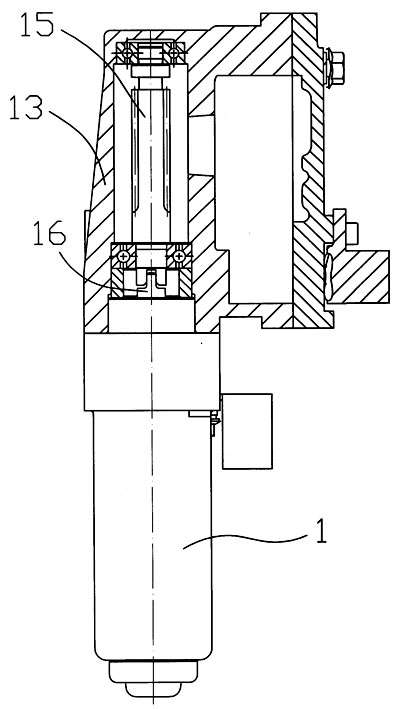

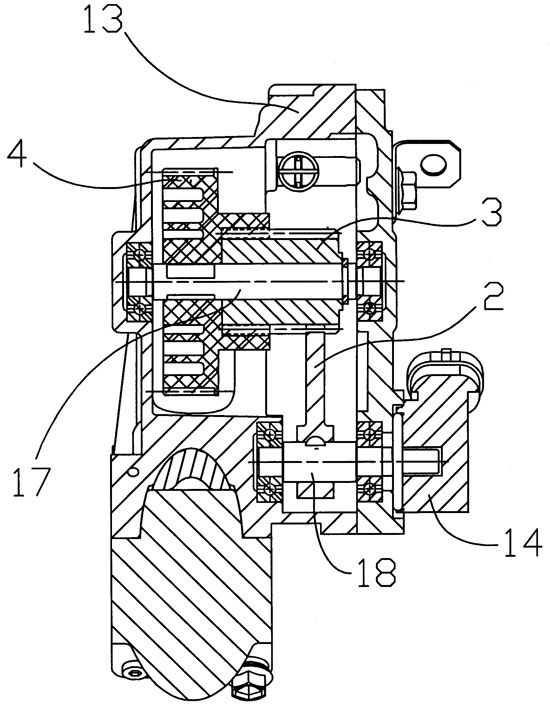

[0018] Such as Figure 1 to Figure 5 As shown, the mechanical cable type automatic transmission clutch actuator includes a housing 13, a driving mechanism installed on the housing 13, and an angle sensor 14. The driving mechanism includes a motor 1, a worm gear 4, a worm rod 15, a transition gear 3, and a gear Bar 9 and dragline 8, worm rod 15 are installed on the housing 13 by two rolling bearings, and one end of worm rod 15 is connected with motor shaft 16. The turbine 4 and the transition gear 3 are installed on the rotating shaft 17 through key connection, and the rotating shaft 17 is installed on the housing 13 through two rolling bearings, so that the turbine 4 and the transition gear 3 are installed on the housing 13 . The worm wheel 4 meshes with the worm rod 15 , and one end of the worm wheel 4 is provided with internal teeth, and meshes with the transition gear 3 through the internal teeth. The rack 9 is installed on the housing 13 through the linear bearing 5, mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com