Plane cross slip ring for scroll compressor

A scroll compressor, a cross slip ring technology, applied in the components of the pumping device for elastic fluid, the rotary piston type machinery, the rotary piston type/swing piston type pump components, etc., can solve the problem of the scroll compressor. Increased noise and vibration, shortened compressor life, harmful vibration and noise, etc., to eliminate noise, extend working life, and improve working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

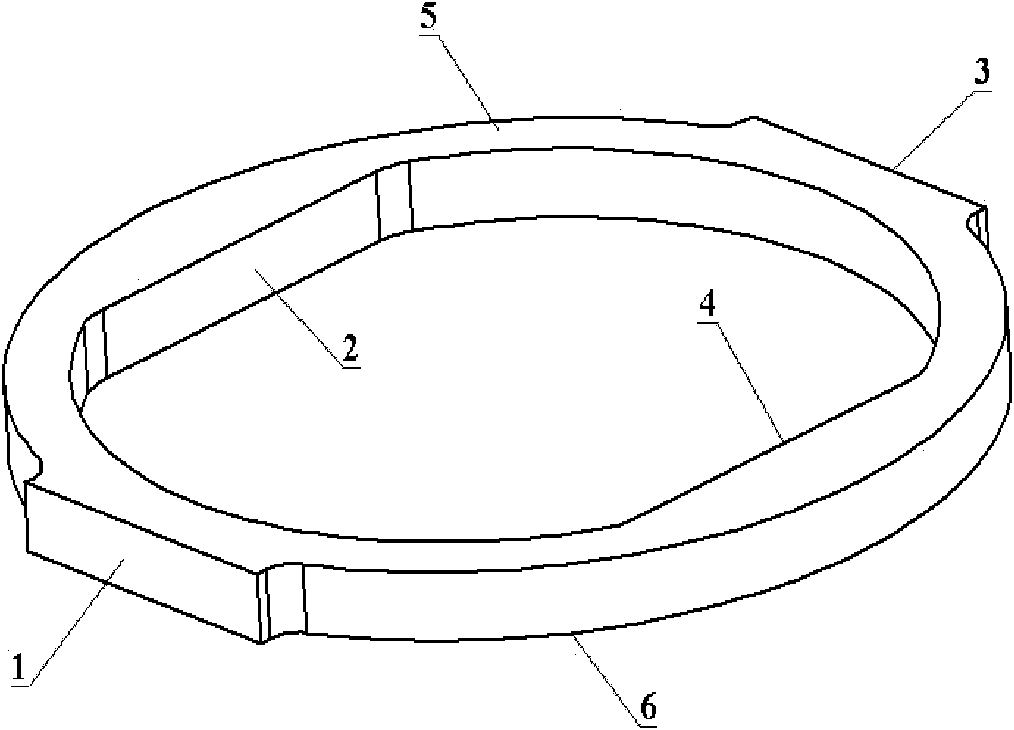

[0031] see Figure 1-12 , although the principles of the present invention can be applied to many different types of scroll machines, but for the sake of illustration, a hermetic scroll compressor is described here.

[0032] Referring to the drawings below, in all the drawings, the same reference numerals represent the same components or faces of the components in all the drawings. Figure 7 A schematic cross-sectional view of a scroll compressor is shown in , which includes a unique planar Oldham slip ring according to the present invention, and is indicated by reference numeral 14 . The scroll compressor includes a compressor middle casing 22, a lower casing 24, an upper casing 26, a bracket 17, and the bracket is fixed in the compressor middle casing 22; the fixed scroll 15 is fixed in the compressor casing; the moving scroll The turntable 13 cooperates with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com