String-type wind wheels and magnetic levitation string-type windmill

A technology of magnetic levitation and wind wheel, which is applied in the direction of wind power generators, wind power generation, wind power generators, etc. at right angles to the wind direction, can solve problems such as the contradiction between efficiency and startability, the impact on aerodynamic efficiency, and the increase in cost, so as to reduce the installed cost and increase the cost. Sweeping area, good benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

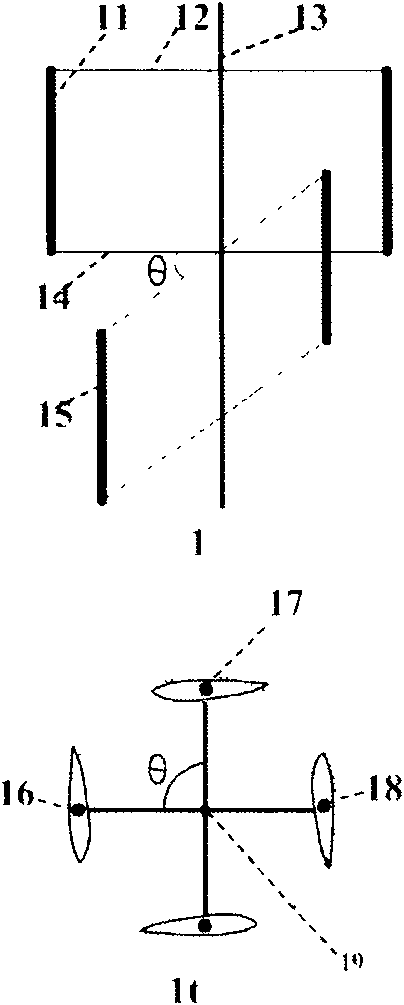

[0039] Example 1: A series of wind rotors composed of two H-type 2-blade wind rotors.

[0040] as attached figure 1 shown. In the figure: 11 is the blade of the upper single wind rotor, 12 is the upper horizontal support arm of the upper single wind rotor blade, 13 is the hub or rotating shaft of the string type wind rotor, and 14 is the lower part of the upper single wind rotor blade. Horizontal support arm, 15 is the fan blade of lower layer single wind wheel.

[0041] The string type wind wheel is composed of two single wind wheels up and down. Each single wind rotor is in the shape of "middle", each has 2 straight blades, the blade support arm is horizontally supported, the lower horizontal support arm of the upper single wind rotor and the upper horizontal support arm of the lower single wind rotor form a Cross-shaped, they are on the same horizontal plane, and the θ angle in the vertical projection of the preferred configuration is 360 / (2+2)=90 degrees.

example 2

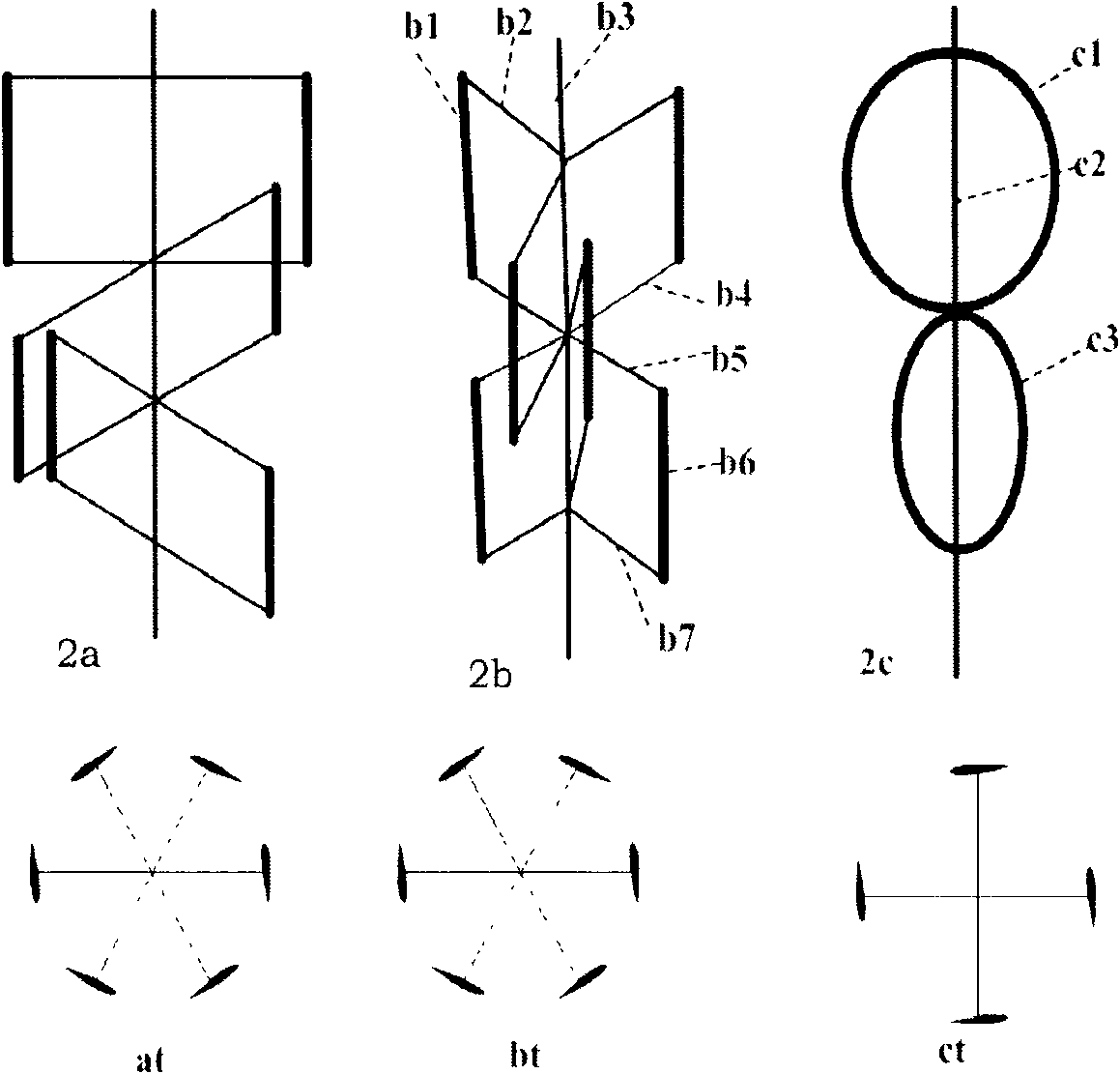

[0042] Example 2 is a series wind rotor composed of two three-bladed H-type wind rotors.

[0043] as attached figure 2 Shown in 2b. In the picture:

[0044] b1. The blades of the upper single wind rotor, b2: the upper horizontal support arm of the upper single wind rotor, b3: the central axis of the wind rotor, b4: the lower horizontal support arm of the upper single wind rotor, b5: the upper horizontal support of the lower single wind rotor Arm, b6: the blades of the lower single wind rotor, b7: the lower horizontal support arm of the lower single wind rotor

[0045] Each layer of single wind rotor is composed of a 3-blade H-shaped turbine, the blade support arm adopts horizontal support, the lower horizontal support arm of the upper unit and the upper horizontal support arm of the lower unit constitute type, they are in the same horizontal plane, and the θ angle of the vertical projection of the preferred configuration is 360 / (3+3)=60 degrees.

[0046] The above exampl...

example 3

[0047] Example 3 adopts a triangular-supported string wind rotor composed of two H-shaped 2-blade single wind rotors.

[0048] as attached Figure 7 shown. In the picture:

[0049] 71 is the blade of the upper single wind rotor, 72 is the oblique support arm, 73 is the central axis of the wind rotor, 74 is the horizontal beam, 75 is the horizontal support arm, 76 is the blade of the lower single wind rotor, 77 is the horizontal support arm, 78 is a horizontal beam, and 79 is a generator.

[0050] Its oblique arm 72 is connected with horizontal crossbeam 74, adopts horizontal arms 75, 77 to support at the intersection of upper floor wind wheel and lower floor wind wheel, 75 and 77 form a cross shape, and they are in the same horizontal plane altogether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com