Ironing machine drying drum heated by electromagnetic induction

An electromagnetic induction heating and ironing machine technology, applied in induction heating, induction heating devices, ironing machines, etc., can solve problems such as tripping, low heat transfer efficiency, and low ironing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

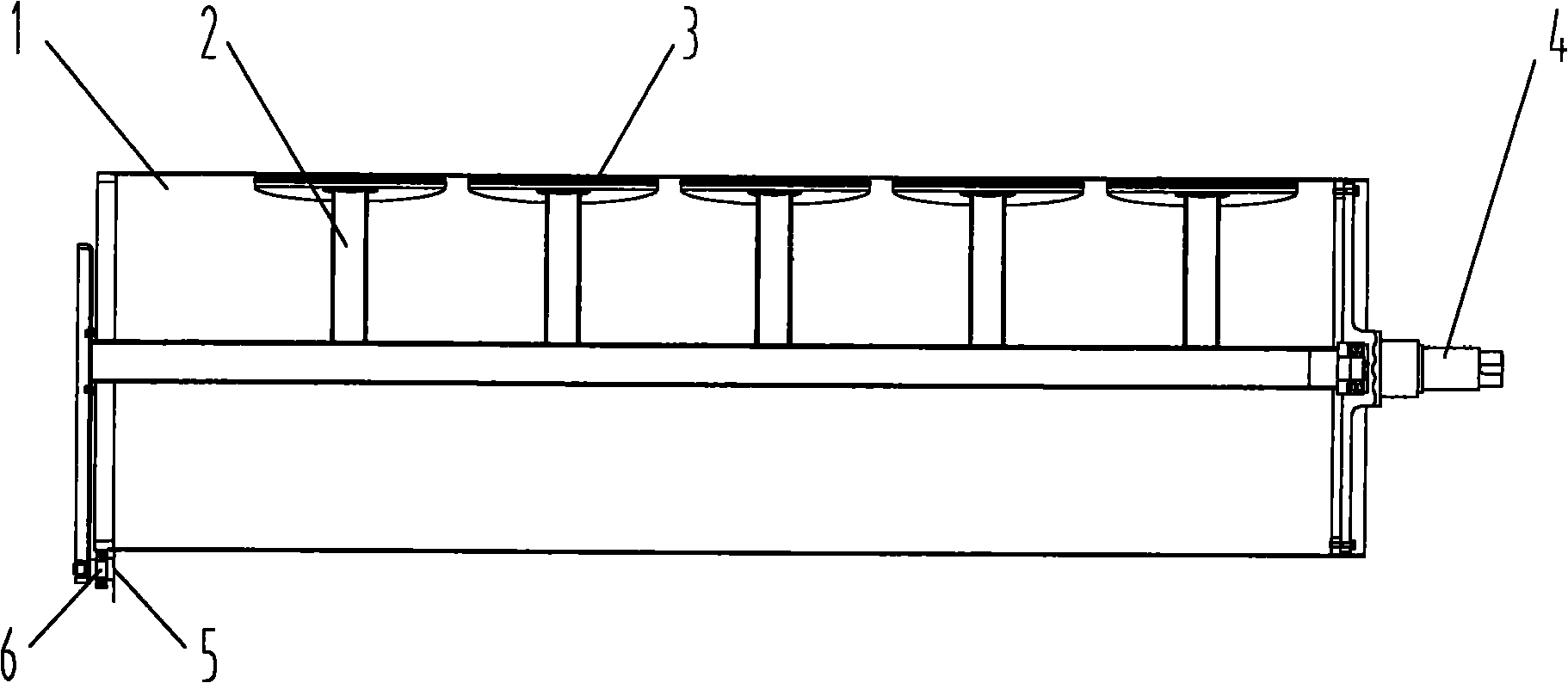

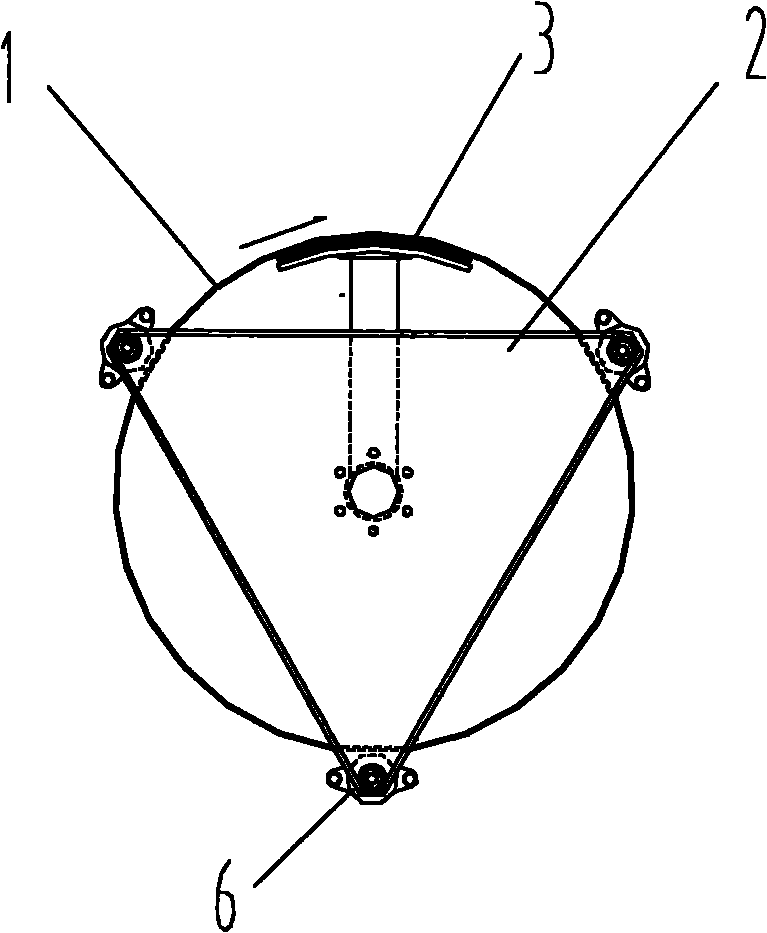

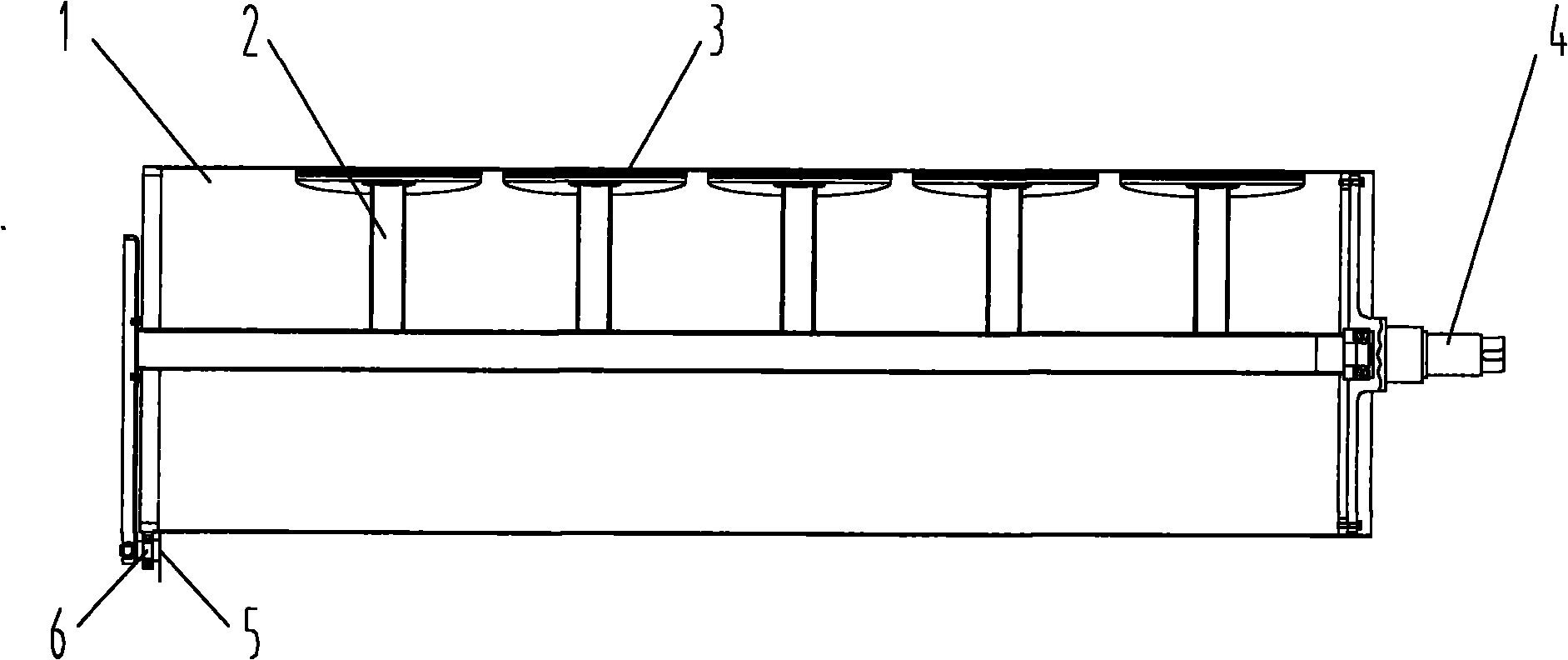

[0010] In the figure, an outer cylinder 1, a rotating shaft 4, a runner 6, an inner support 2, and a frame 5 are included. The edge is supported by at least three runners 6, the inner bracket 2 extends into the outer cylinder 1 through the opening of the outer cylinder 1, the outer side of the inner bracket 2 is fixed on the frame 5, and several inner brackets 2 are fixed on the inner bracket 2. The induction coils 3 are arranged in a line, the convex arc surface of the induction coils 3 coincides with the inner wall of the outer cylinder 1 and there is a gap, and the induction coils are connected to a high-frequency power supply.

[0011] The high-frequency power supply placed in the machine box can convert the industrial frequency power supply into a high-frequency power supply with a frequency up to 20-40kHz. When the current from the high-frequency power supply flows through the induction coil 3, a high-frequency magnetic field is generated. Under the induction of the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com