Self-adaptive control method of spherical numerical-control precision grinding process

An adaptive control and precision grinding technology, which is applied in the direction of automatic grinding control devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of not involving adaptive control of grinding process, and not realizing grinding process control and other problems, to avoid grinding burns, the method is simple, and the effect is easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

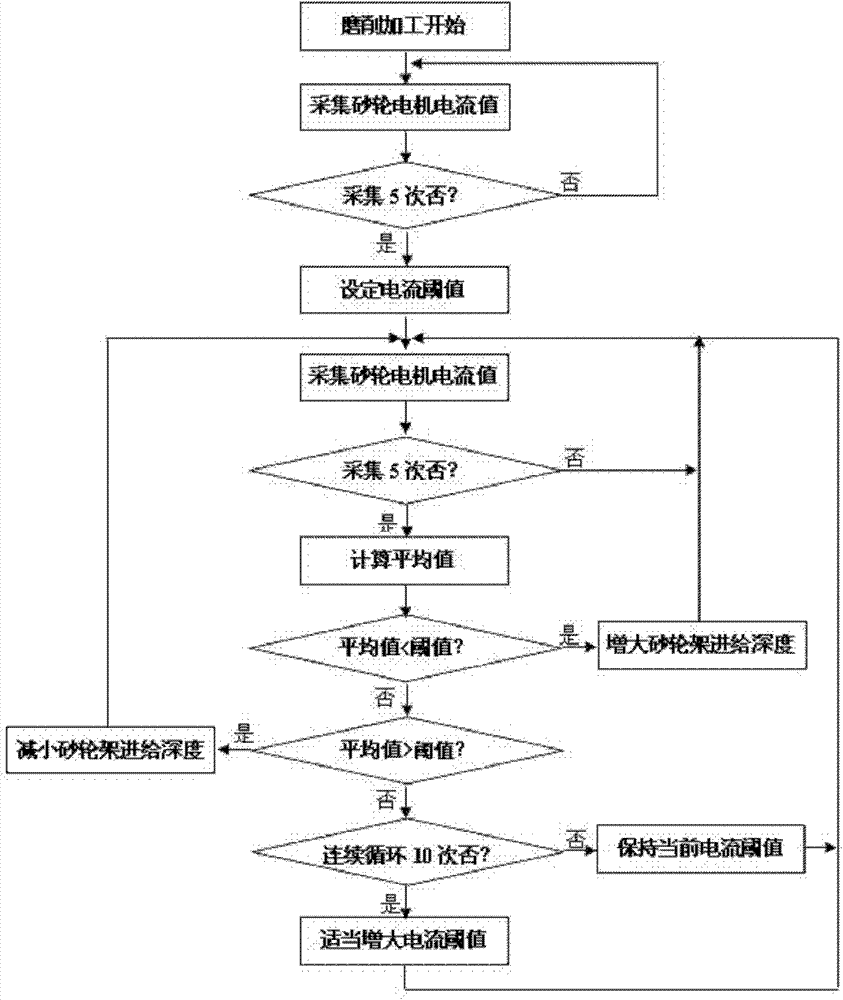

[0016] As shown in the figure, this embodiment specifically includes the following steps:

[0017] The first step is to design the human-machine interface shared by the computer control system and the touch screen on the upper right of the front of the MD6050 CNC precision spherical grinder, and design the grinding wheel speed, feed speed, feed depth (feed amount), and workpiece speed on the interface. The setting, modification and display boxes of various grinding parameters; also designed the dynamic display box of the current value of the grinding wheel drive motor during the grinding process, the display box of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com