Special machine tool for rough milling cylinder head end surface

A special machine tool and end face technology, applied in the field of machine tools, can solve the problems of large operator's physical expenditure, complicated positioning and pressing, unfavorable to large-scale production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

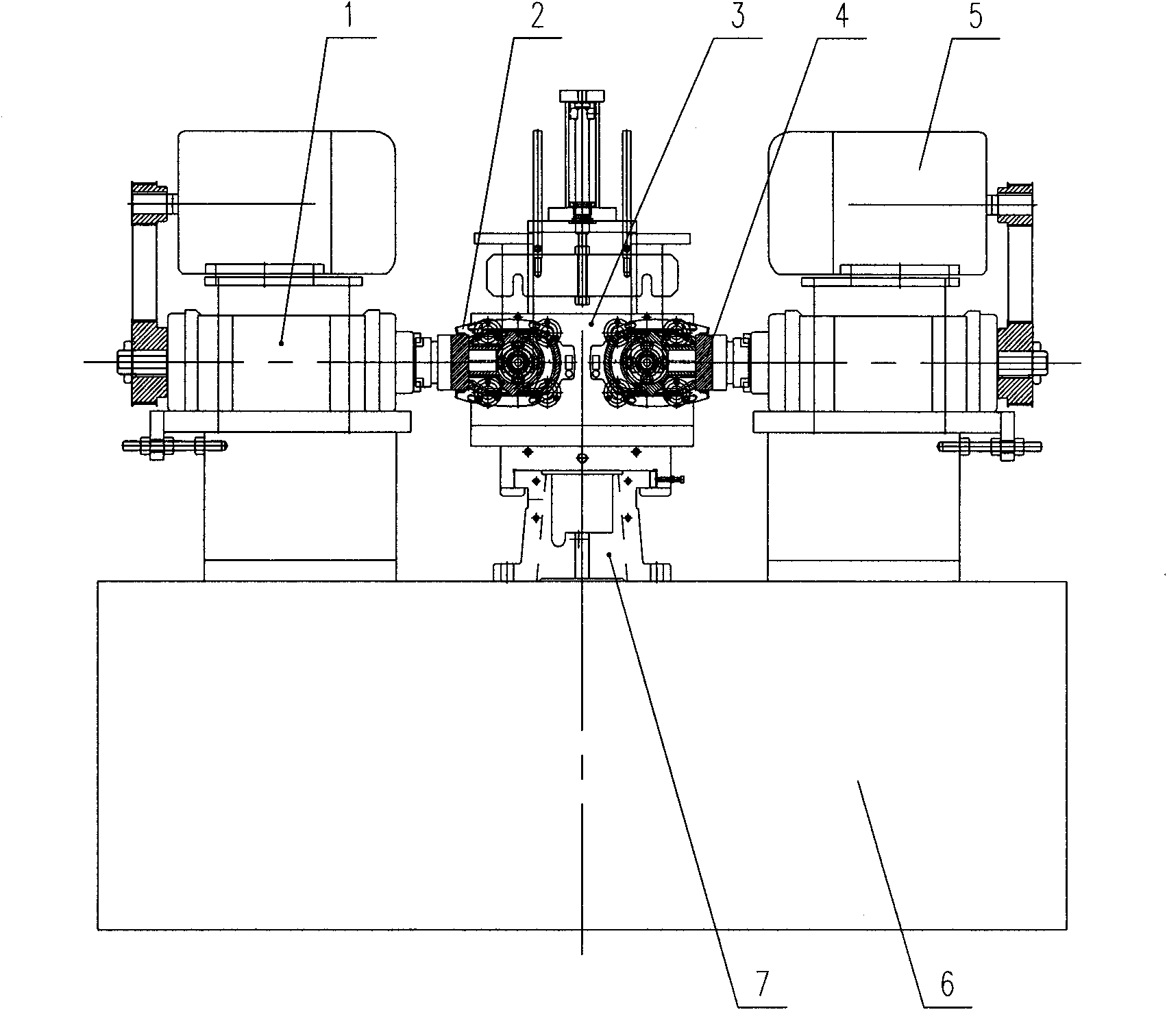

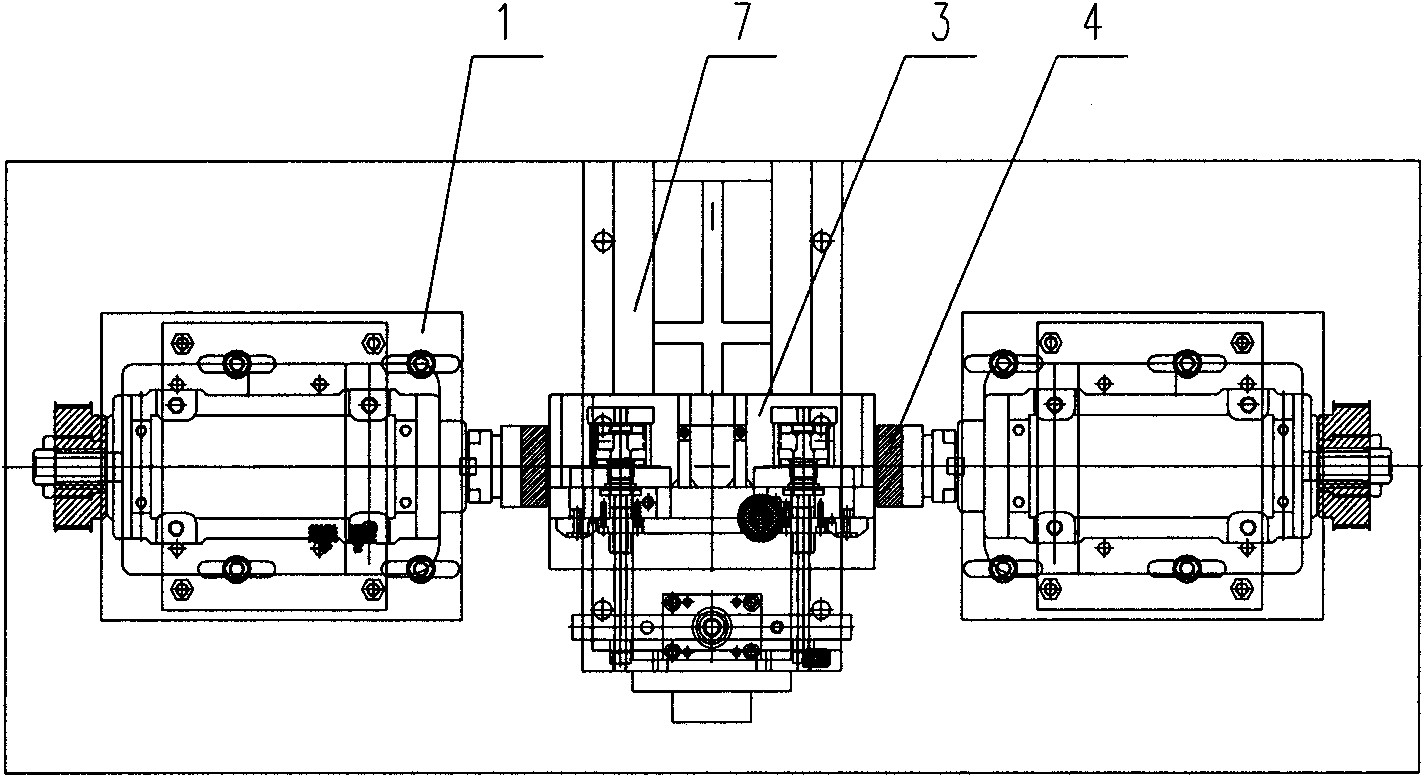

[0024] A special machine tool for rough milling the end face of a cylinder head, including a bed body 6, on which a power head assembly 1 is installed on the upper end face of the bed body. Let me repeat.

[0025] The innovation of the present invention is that: the power head assemblies installed on the upper end surface of the bed body are two coaxial and oppositely arranged, and a slide table 7 is installed on the bed body between the two power head assemblies, and the slide table A clamping body 3 is installed on it, and two workpieces 2 to be processed can be clamped simultaneously on this clamping body.

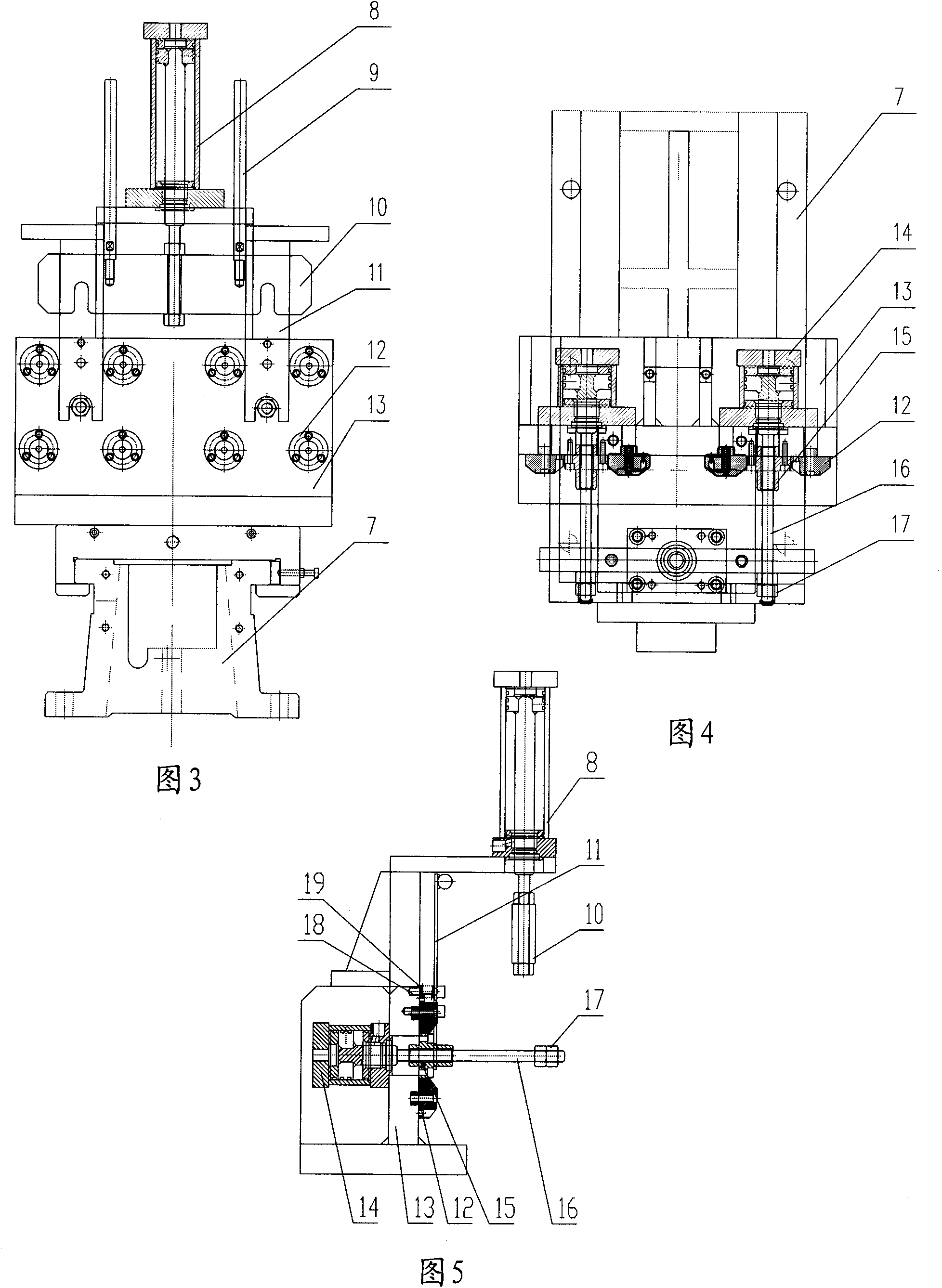

[0026] The clip body includes a frame-type frame 13 and a hydraulic cylinder, and the hydraulic cylinders used in this embodiment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com