Push rod type underwater mud scraper

A technology of mud scraper and push rod type, which is applied in the direction of chemical instruments and methods, separation methods, sedimentation separation, etc., can solve the problems of sludge churning, increased energy consumption of devices, and easy breakage of steel wire ropes, etc., and achieves high processing efficiency and conception Sophisticated, high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

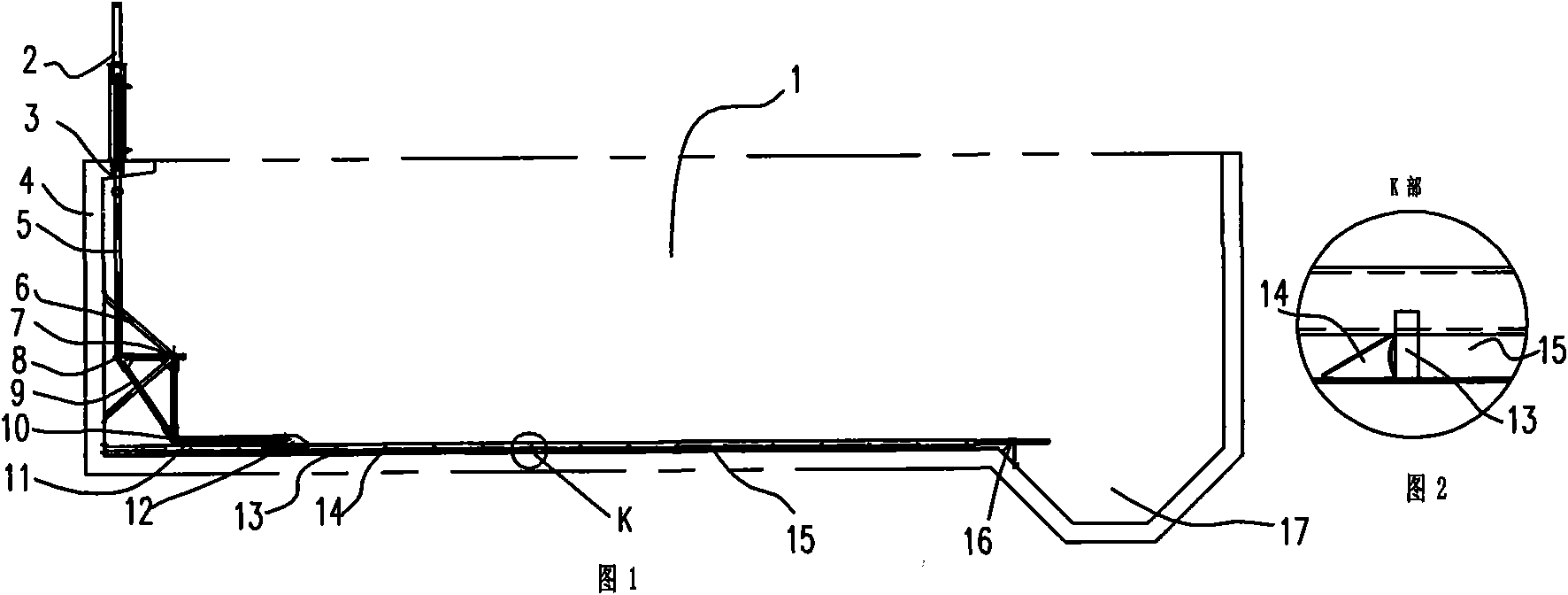

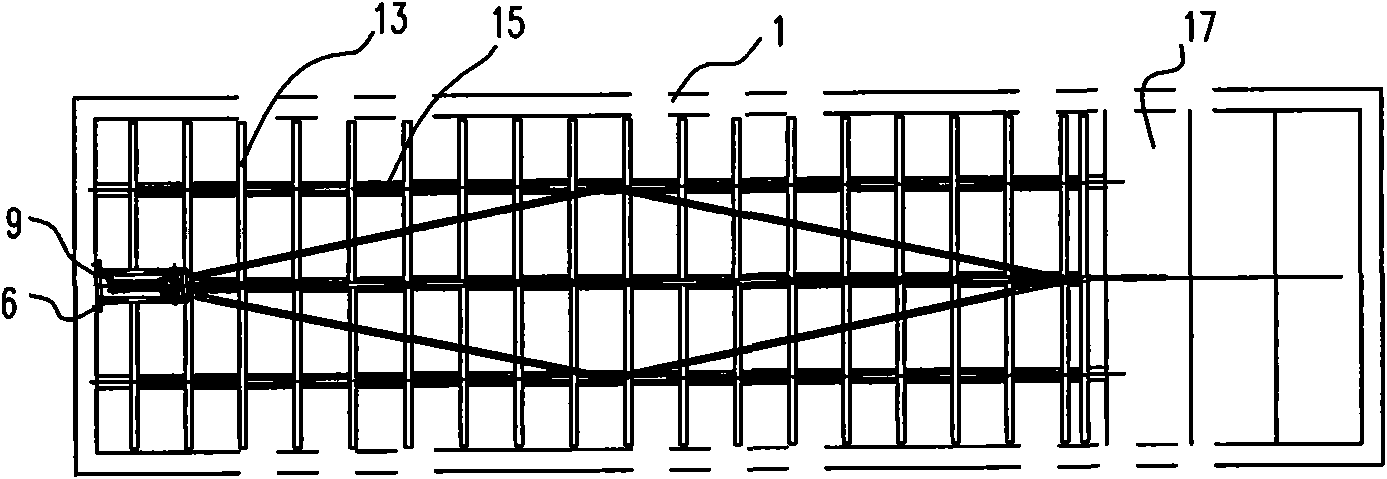

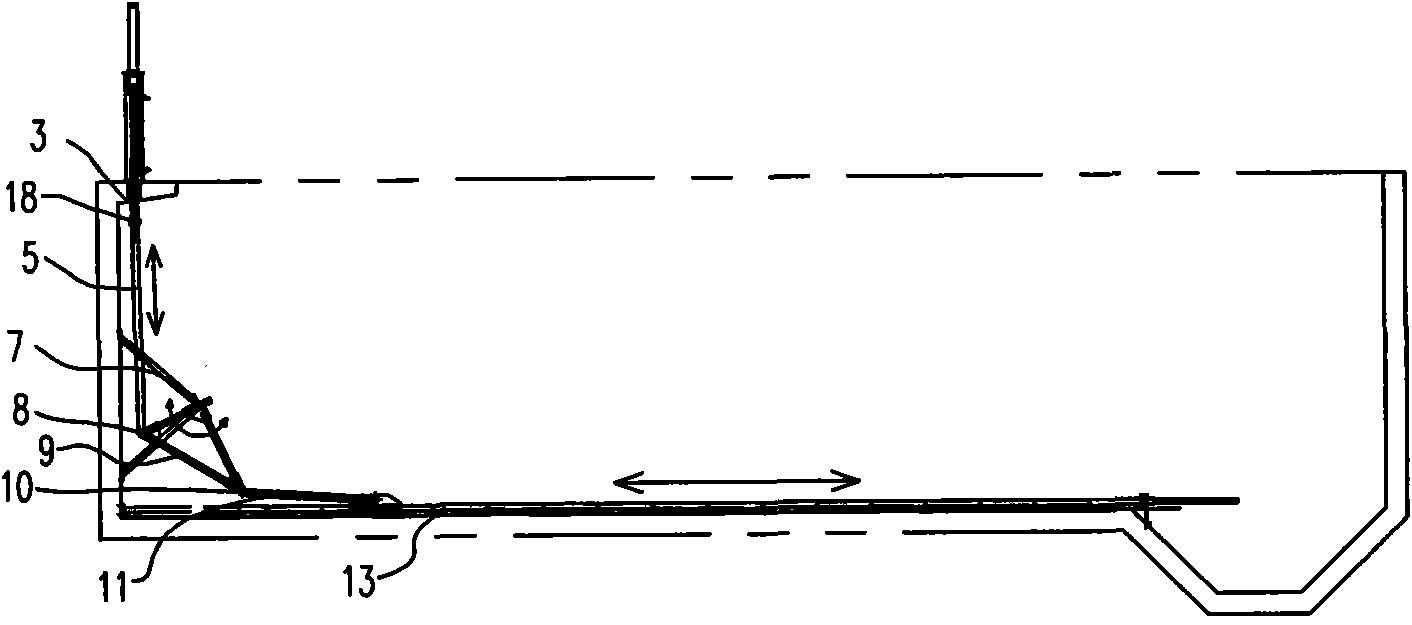

[0016] The present invention as Figure 1-3 As shown, it is set in the sedimentation tank 1 as a whole, and one end of the sedimentation tank 1 is provided with a sludge tank 17. The mud scraper includes a scraper 13, a driving device and a transmission mechanism, and the driving device is fixed on the sedimentation tank 1. On the pool edge at the other end away from the sludge tank 17, the transmission mechanism is provided on the pool wall 4 at this end; the transmission mechanism includes a support 6, a transmission frame 9, a push rod 11, a push rod seat 12, a scraper Plate frame 15 and slat 14 with a wedge-shaped section (scraper 13 and slat 14 can be designed in one, forming a scraper assembly with a wedge surface), and the support 6 is fixedly connected to the end tank The position of the midline in the horizontal direction of the lower part of the wall 4, the transmission frame 9 is triangular, one of the corners of the transmission frame 9 is hinged with the support 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com