Battery tag, battery base and battery

A battery bottom and face sheet technology, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as poor battery cells, limited liquid injection volume, and difficulty in dispensing alkali, so as to improve service life, improve battery performance, The effect of solving the difficulty of injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The battery surface sheet and the battery bottom pad are made of one or more polyolefin materials such as polyethylene and polypropylene, either alone or in combination, and are formed by surface hydrophilic treatment. The material can absorb lye, has liquid retention capacity and is alkali-resistant and insulating, and does not deform at 150 degrees Celsius, so that the battery surface and battery bottom pad can absorb lye, has liquid retention capacity, and is alkali-resistant and insulating.

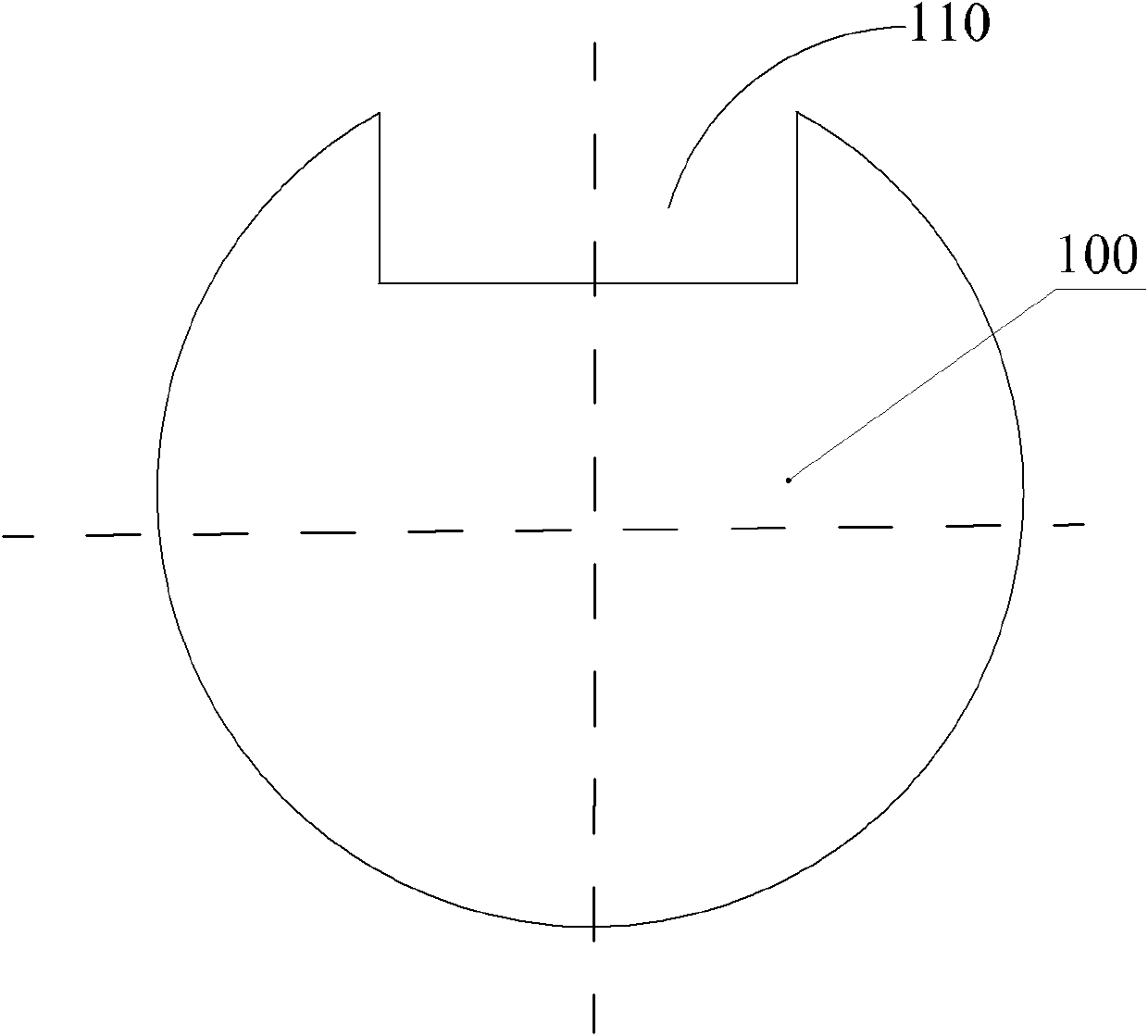

[0021] figure 1 is a schematic diagram of the battery patch structure in one embodiment. The battery face sheet 100 is in the shape of a disc, and a notch 110 is provided on the circumference by cutting or punching. The gap 110 allows the current collector to pass through the surface sheet 100 and connect with the positive elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com