Salt mist corrosion test box

A technology of salt spray corrosion and test chamber, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. It can solve the problems of complex test procedures, corrosion of precision instruments and equipment, and long time, so as to achieve smooth and smooth surface, Prevent the leakage of salt mist and the effect of precise distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

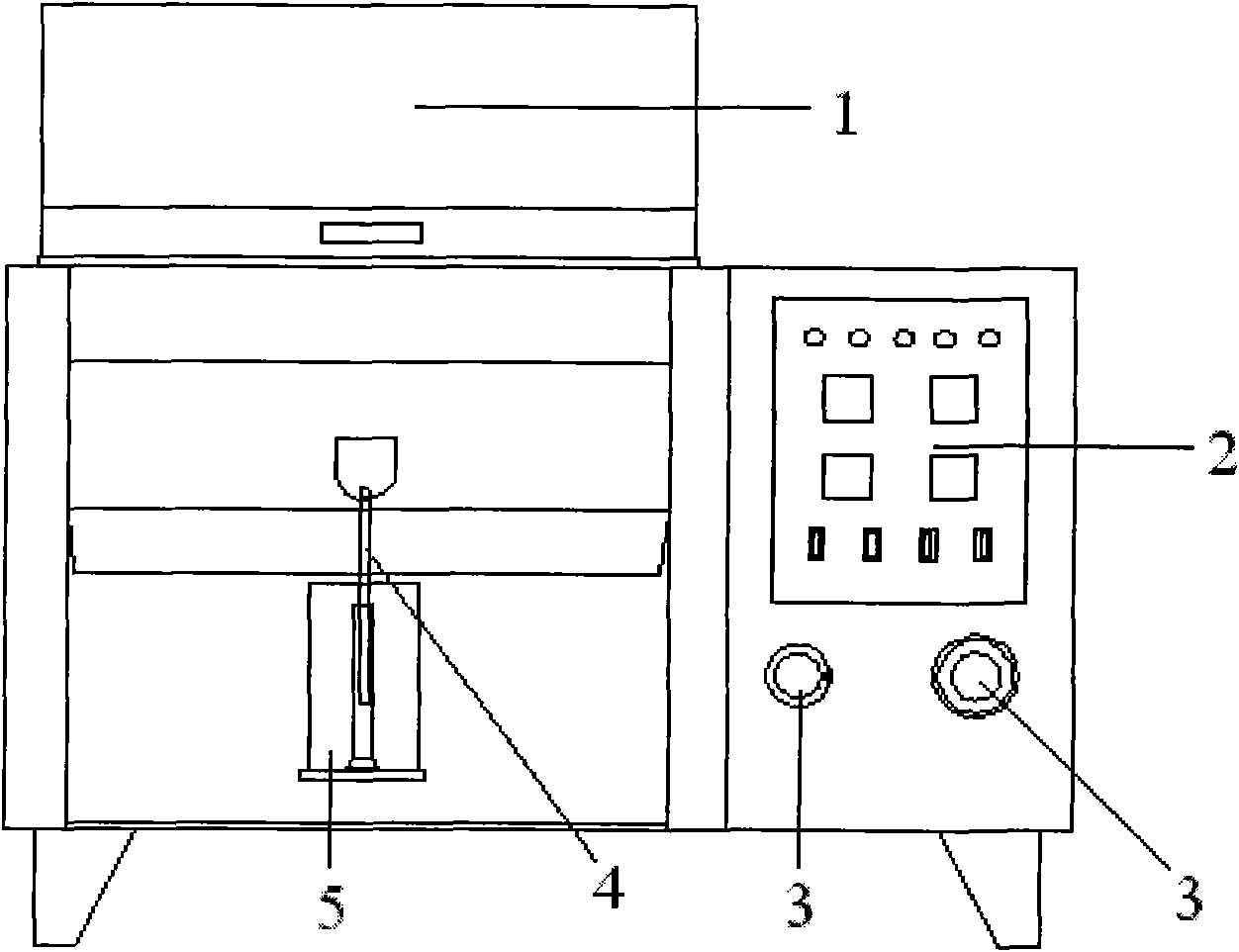

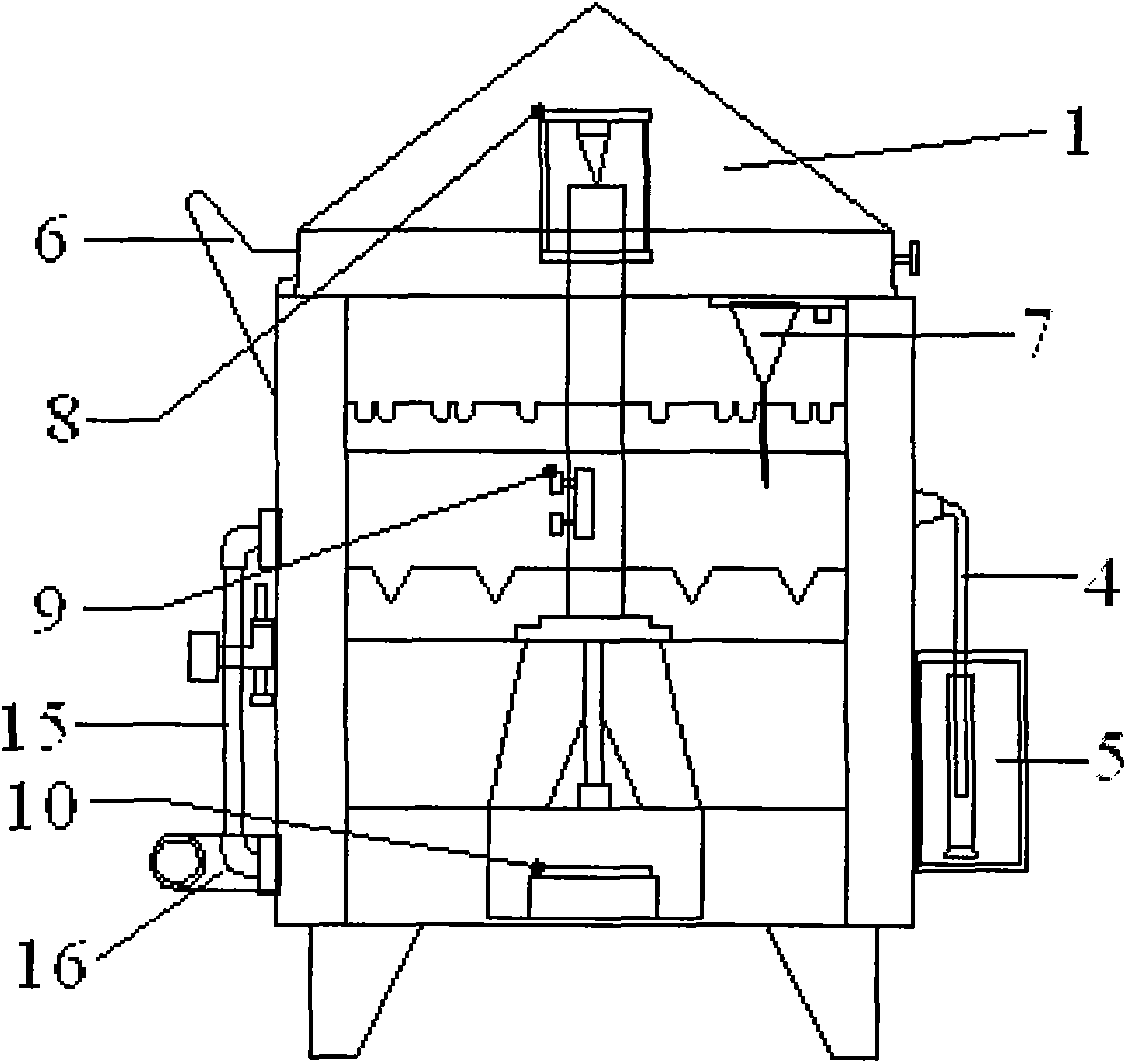

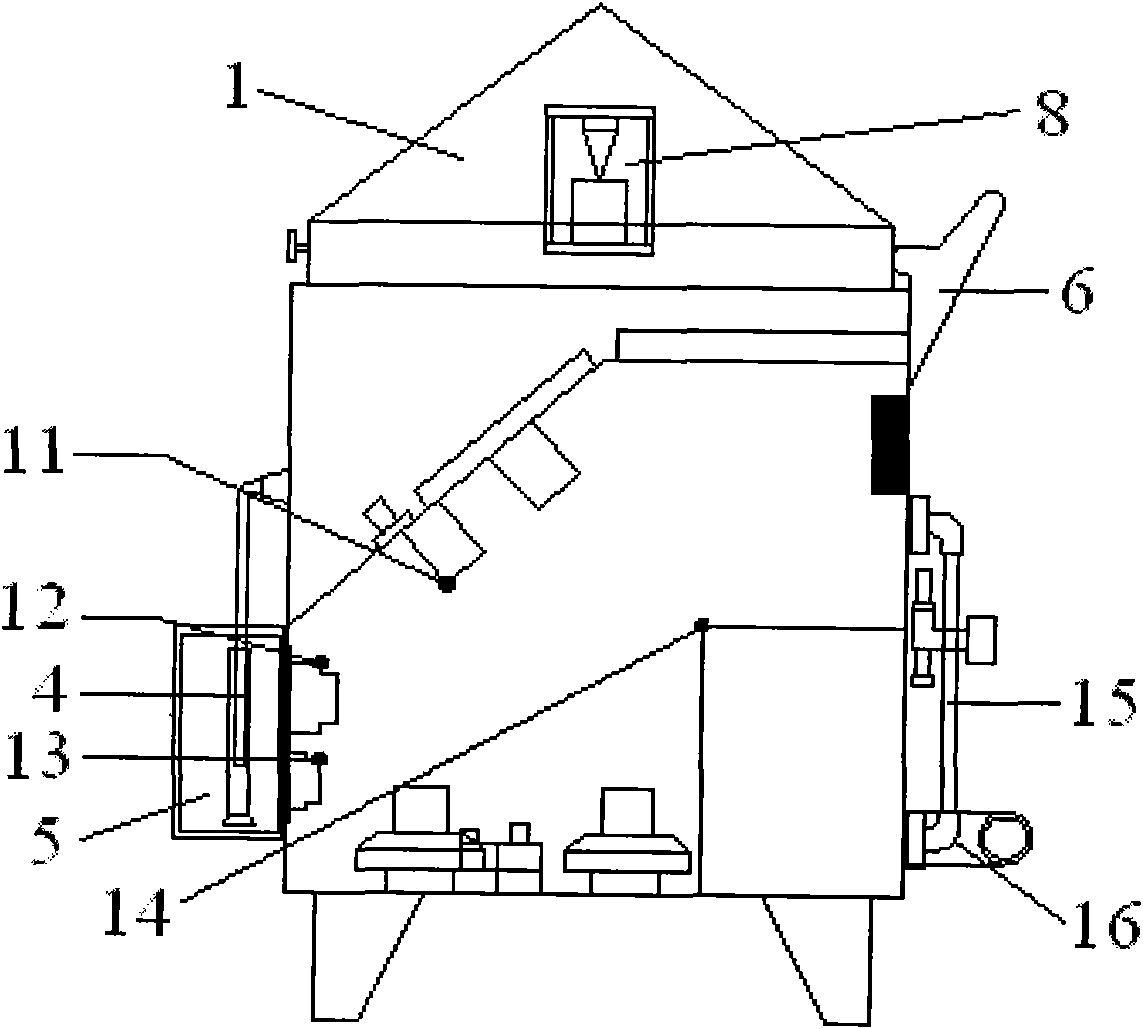

[0022] A salt spray corrosion test chamber, its front view is as follows figure 1 As shown, the internal structure diagram is shown in figure 2 As shown, the test chamber includes a control panel 2, a measuring cylinder 4, a heating pipe 10, a drainage pipe 15, a spray system and an electrical system. The body of the fog corrosion test chamber is made of polyvinyl chloride (PCV) imported from Germany. The top of the salt spray corrosion test chamber is provided with a transparent case cover 1, one side of the case cover 1 is provided with a support rod 6, the lower part of the case cover 1 is provided with a triangular funnel 7, the control panel 2 is provided on the right side of the front of the test chamber, and the measuring cylinder 4 is covered A measuring cylinder sheath 5 is arranged in the middle of the front of the test box, and a drain pipe 15 is arranged at the back of the test box and is connected with a saturated container 14 in the test box, and the saturated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com