Electromagnetic synchronizer actuating system

A synchronizer, actuation technology, applied in the direction of transmission control, elements with teeth, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses.

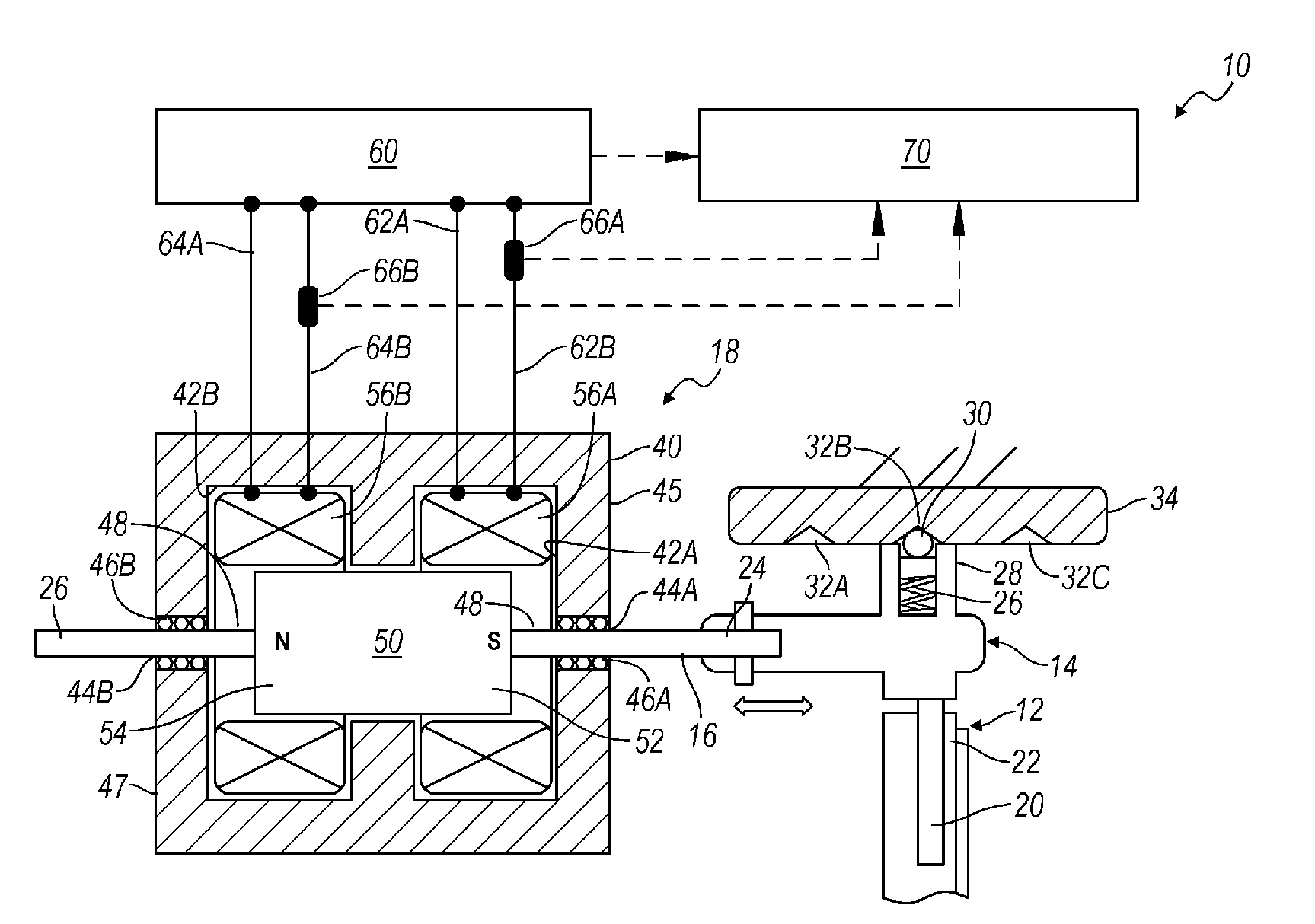

[0054] refer to figure 1 , reference numeral 10 shows and generally indicates a synchronizer actuation assembly. The synchronizer actuation assembly 10 is configured to actuate at least one synchronizer 12 in an automated manual transmission or a dual clutch transmission. The transmission may have any number of synchronizers 12 and any number of synchronizer actuation assemblies 10 without departing from the scope of the present invention. Synchronizer 12 is a bi-directional synchronizer movable between a first engaged position, a second engaged position, and a neutral or disengaged position. In each engaged position, synchronizer 12 is operable to rotationally couple two components, such as shafts and gears, together to transmit torque therebetween. In a neutral position, synchronizer 12 is not engaged with at least one of the components and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com