Multi-stage and multi-pipe efficient jet pump

A high-efficiency jet and jet technology, applied in the field of jet pumps, can solve problems such as difficult to meet output pressure and delivery efficiency, abrasion of jet tubes, and reduced service life of jet pumps, so as to improve the flow state of the medium, increase the suction capacity, and reduce pressure. head effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

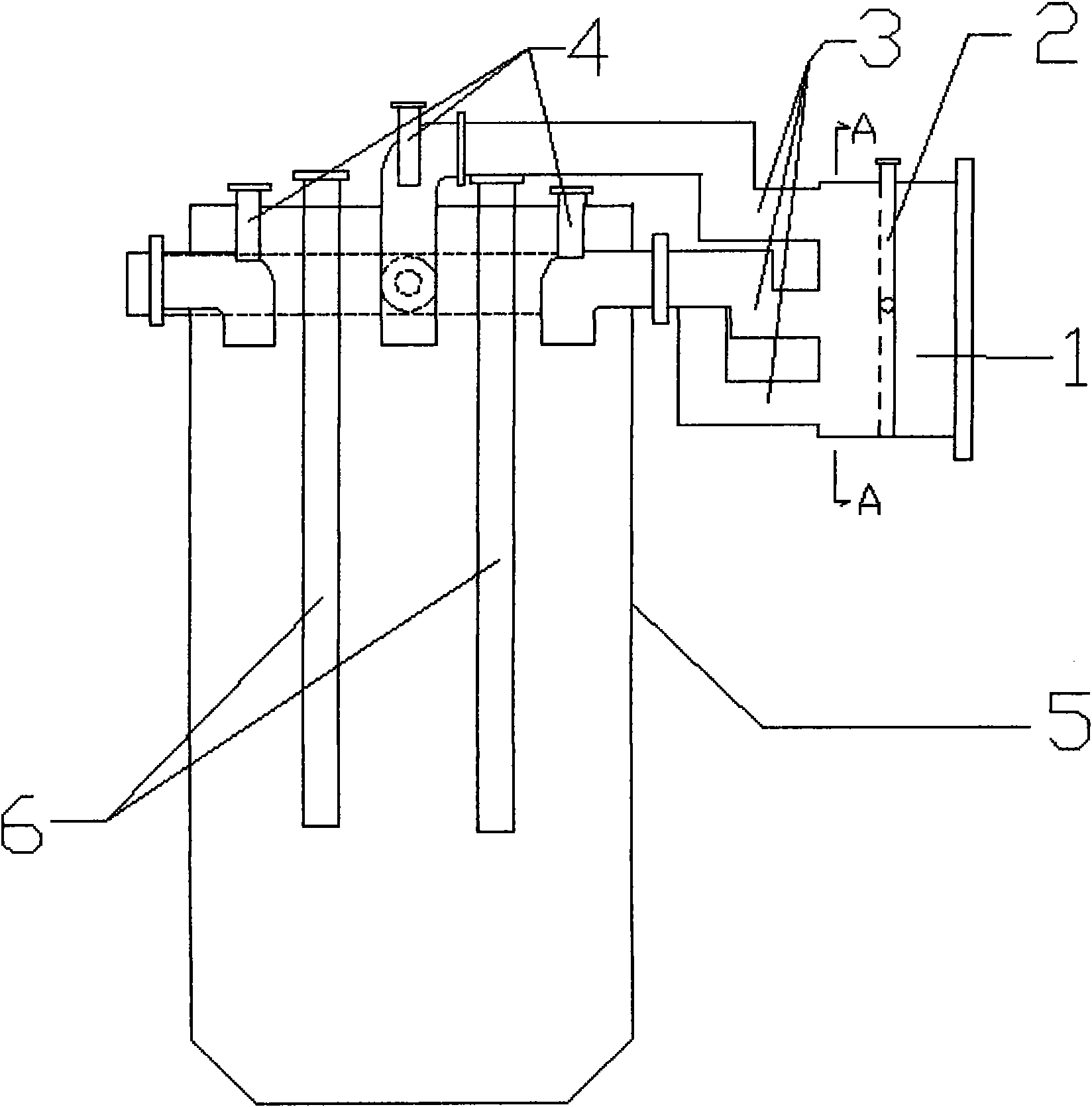

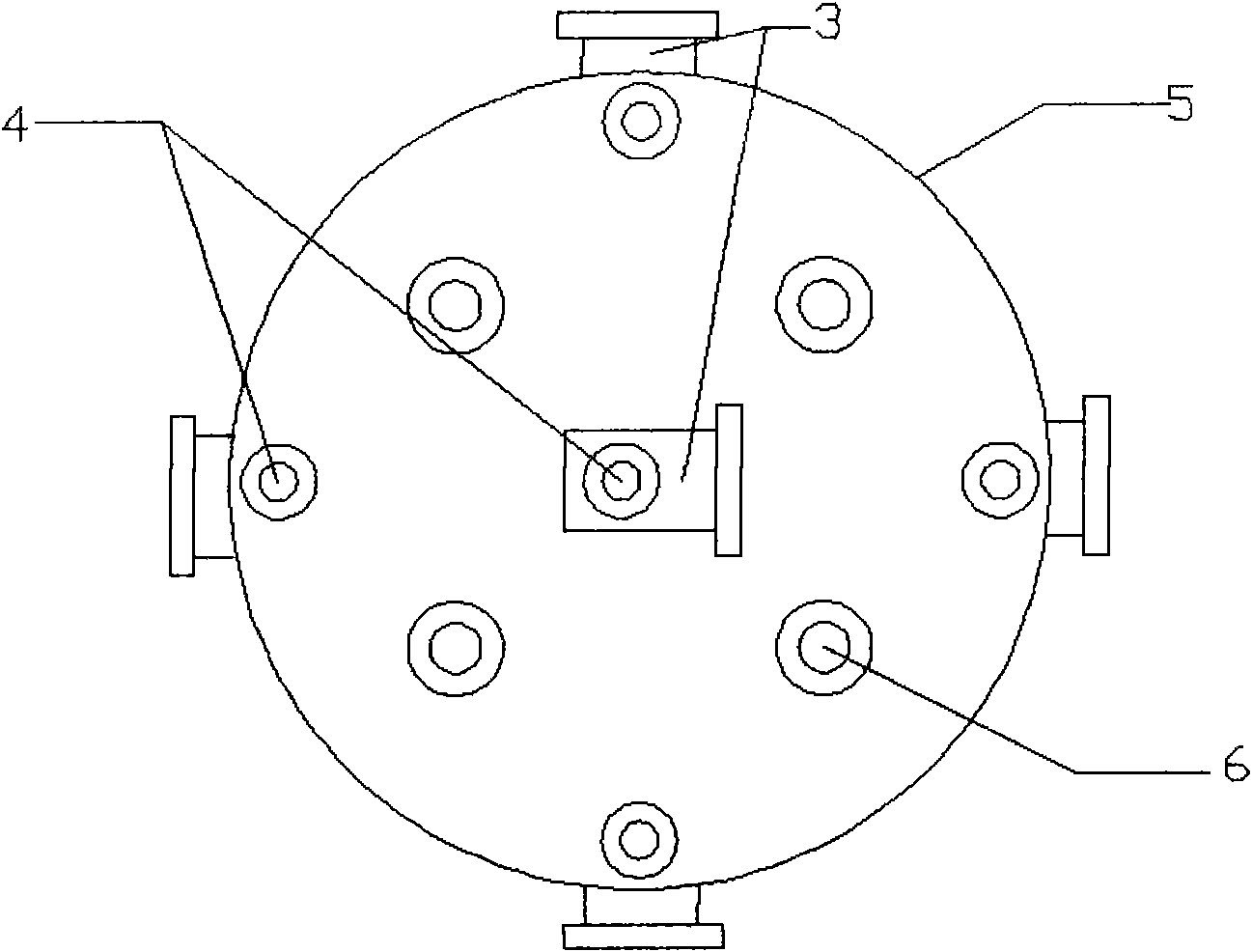

[0019] see figure 1 , 2 And 3, the present invention provides a kind of multi-stage multi-tube high-efficiency jet pump, comprising a pump body 5, the pump body is provided with a pump body inlet and an outlet, and the outlet of the pump body can be set to a tapered mouth to facilitate Connection with next-level equipment or forming a jet.

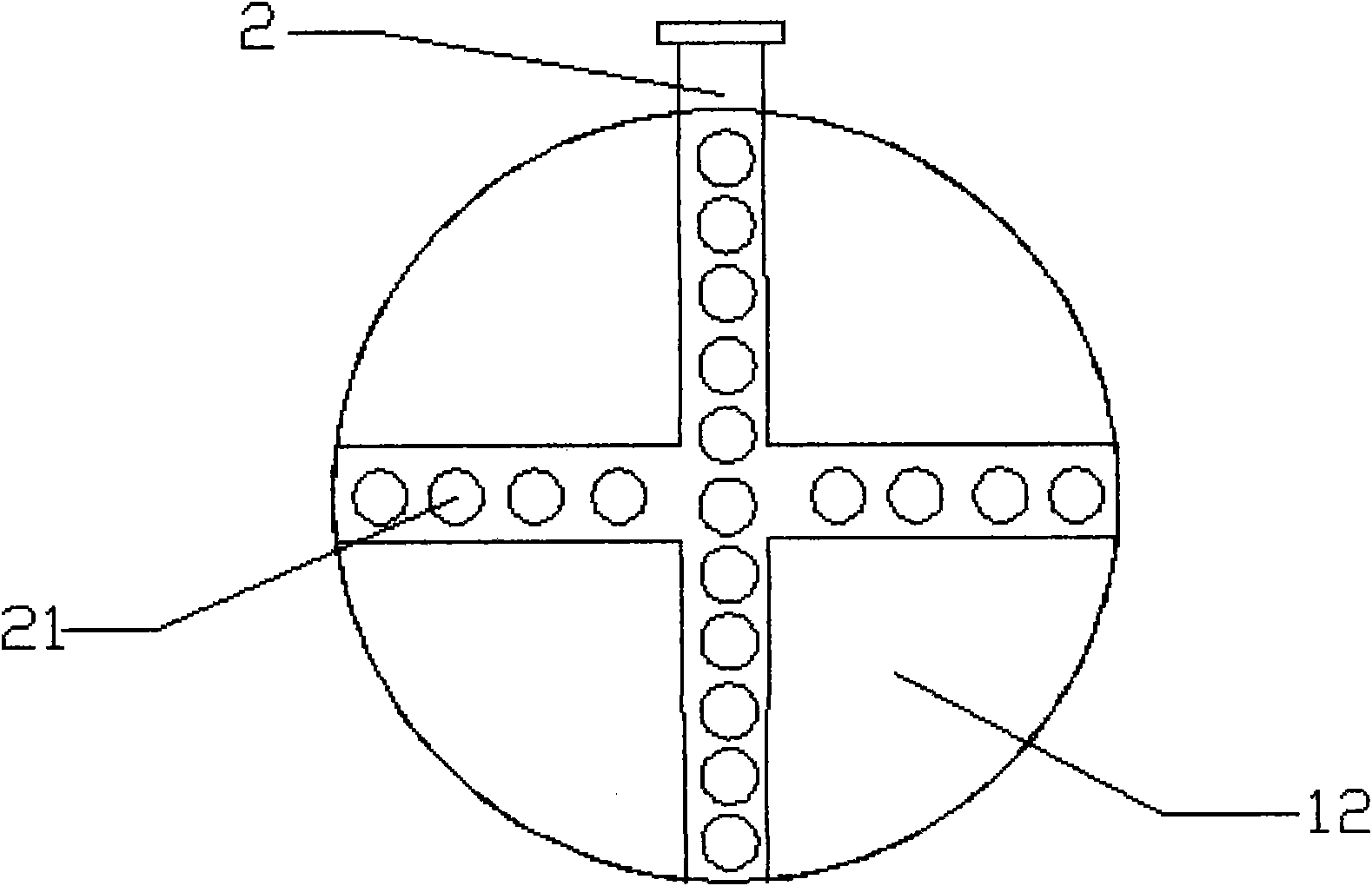

[0020] The multi-stage multi-tube high-efficiency jet pump also includes a suction pipe, a primary jet pipe 6, a secondary jet pipe 2 and a tertiary jet pipe 4, the suction pipe is connected to the pump body and communicated with the pump body, The inlet of the suction pipe can be connected to the source of the pumped medium for delivering the medium in the suction pipe to the pump body; the secondary jet pipe penetrates into the suction pipe from the outside of the suction pipe, and is connected with the The suction pipe is connected to the inner cavity of the suction pipe, and its outlet 21 faces the medium flow direction in the suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com