High-carbon and low-sulfur type gold ore floating agent and floating method thereof

A flotation agent and gold ore technology, applied in the field of gold separation, can solve the problems of difficult control and complex process, and achieve the effects of high recovery rate, simple separation process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

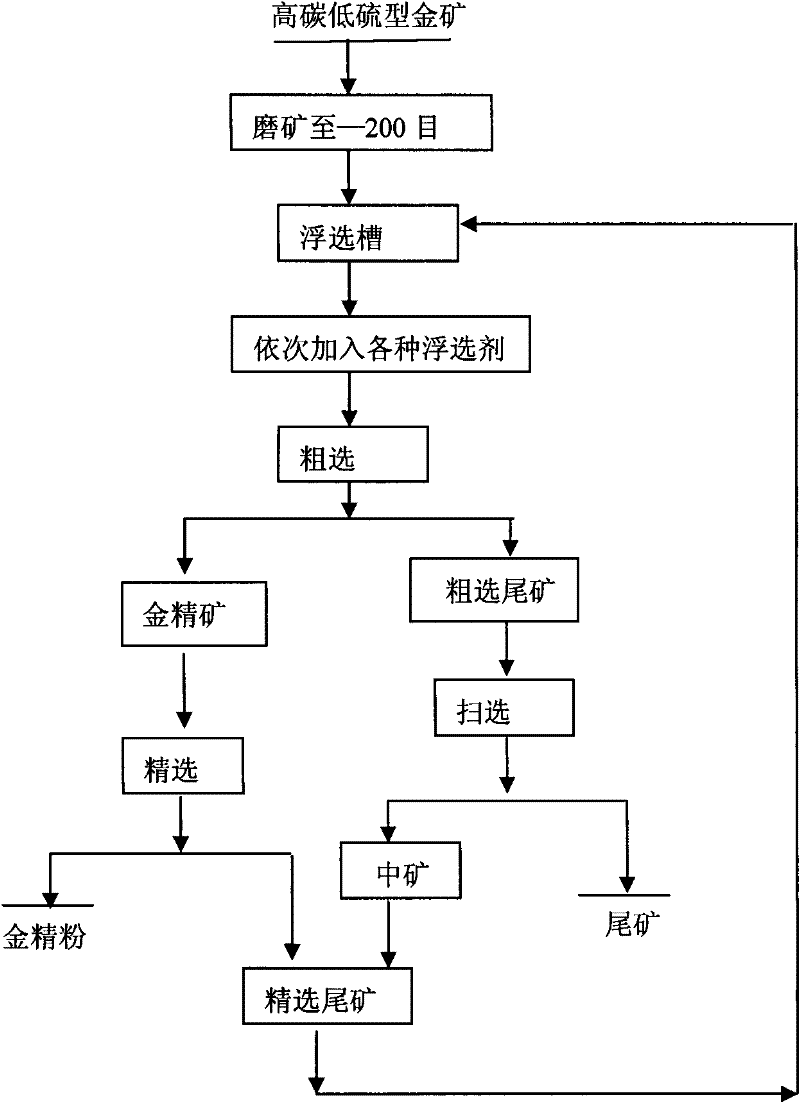

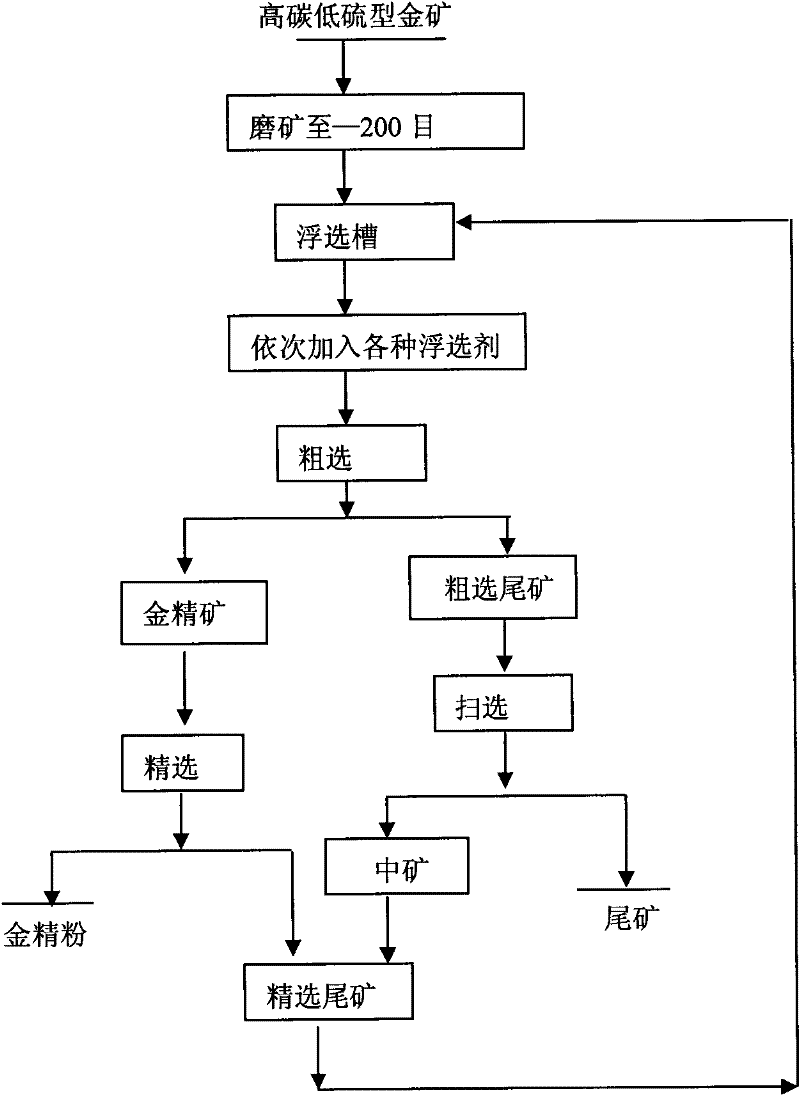

Method used

Image

Examples

Embodiment 1

[0045] a. Take 1000g of a high-carbon and low-sulfur gold ore in Jilin, pulverize it, and grind it to -200 mesh;

[0046] b. Put the high-carbon gold ore powder ground to -200 mesh in the sorting tank, and adjust the slurry to a concentration of 40% according to the mass percentage;

[0047] c. According to the mass ratio of high-carbon and low-sulfur gold ore powder before pulping, 2.0ml concentration of 98% H 2 SO 4 , 0.16g Na 2 S and 1.8gNa 2 SO 3 , stir and activate for 2 minutes;

[0048] d. Add 0.1g NaCl and 0.9g CaO in sequence according to the mass ratio of high-carbon gold ore powder before pulping 2 , 0.06g No. 2 oil, 0.2g butyl xanthate and 0.08g butylamine black medicine, stir well;

[0049] e, roughing for 8 minutes to obtain gold concentrate and roughing tailings;

[0050] f, the gold concentrate is selected for 3 minutes to obtain gold concentrate powder, and the tailings are discarded;

[0051] g. After scavenging the roughing tailings for 10 minutes, t...

Embodiment 2

[0055] a. Take 2000g of a high-carbon and low-sulfur gold ore in Liaoning, crush it, and grind it to -200 mesh;

[0056] b. Put the high-carbon gold ore powder ground to -200 mesh in the sorting tank, and adjust the slurry to a concentration of 40% according to the mass percentage;

[0057] c. According to the mass ratio of the high-carbon gold ore powder before pulping, add 2.0ml of 98% H 2 SO 4, 0.5g Na 2 S and 2.0gNa 2 SO 3 , stir and activate for 3 minutes;

[0058] d. Add 0.9g NaCl and 1.8gCaO, 0.06g No. 2 oil, 0.18g isoamyl xanthate and 0.09g butylamine black medicine in sequence according to the mass ratio of the high-carbon and low-sulfur gold ore powder before mixing, and stir evenly ;

[0059] e, roughing for 10 minutes to obtain gold concentrate and roughing tailings;

[0060] f, the gold concentrate was selected for 5 minutes to obtain gold concentrate powder, and the tailings were discarded;

[0061] g. The roughing tailings are swept for 11 minutes to obt...

Embodiment 3

[0065] a. Take 2000g of a high-carbon and low-sulfur gold ore in Guizhou, crush it, and grind it to -200 mesh;

[0066] b. Put the high-carbon and low-sulfur gold ore powder ground to -200 mesh in the sorting tank, and adjust the slurry to a concentration of 40% according to the mass percentage;

[0067] c. According to the mass ratio of the high-carbon gold ore powder before pulping, add 1.5ml of 98% H 2 SO 4 , 2.2g Na 2 S and 1.08gNa 2 SO 3 , stir and activate for 4 minutes;

[0068] d. Add 0.8g NaCl and 1.2g CaO in sequence according to the mass ratio of high-carbon gold ore powder before pulping 2 , 0.048g No. 2 oil, 0.19g butyl xanthate, 0.02g isopentyl xanthate and 0.04g butylamine black medicine, stir well;

[0069] e. Rough selection for 11 minutes;

[0070] f. Select for 5 minutes, discard the tailings, and obtain gold concentrate;

[0071] g. Sweeping for 10 minutes to obtain middle ore and tailings;

[0072] h. The selected tailings and middle ore return to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com