Method for processing small red bean

A processing method and technology for adzuki bean, which are applied in the fields of application, food preparation, food science, etc., can solve the problems that the adzuki bean product cannot be used as the raw material of bean rice or bean porridge, the appearance and flavor of the adzuki bean product are reduced, and the appearance of the adzuki bean processed product is affected. The appearance and shape are well maintained, suitable for large-scale promotion and application, and the processing cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Cooking

[0048] Add red bean into water, heat, add edible white vinegar when the temperature rises to 96°C, mix with red bean and water, adjust the pH of the red bean aqueous solution to 4.08, keep the temperature at 96°C and cook for 39 minutes, then cool, wash and filter , to obtain boiled red beans, wherein the weight ratio of red beans and water is 100:600.

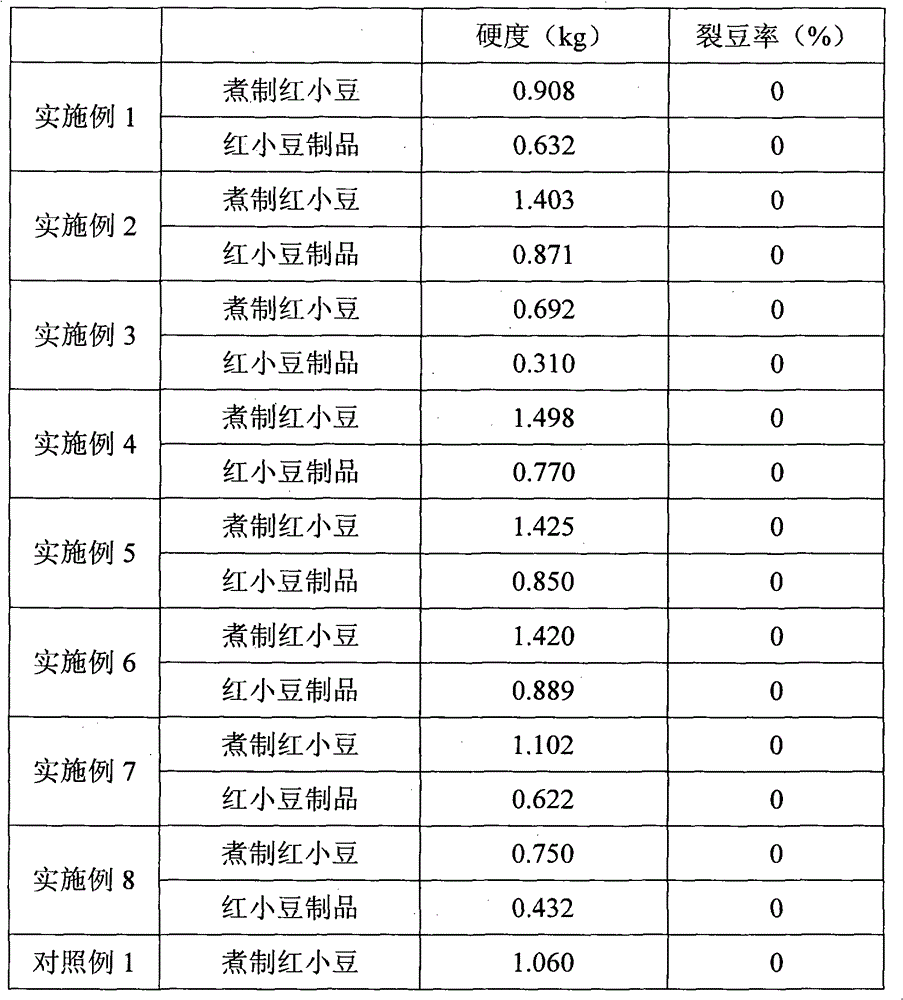

[0049] The hardness of the boiled red bean was adopted GWJ-1 type grain hardness meter, and the measurement results are shown in Table 1.

[0050] 2. Vacuum treatment

[0051] The boiled red bean is placed in a vacuum packaging bag, vacuumized, then sealed, and packaged, wherein the absolute pressure during the vacuumization process is 1.0kPa, and the vacuumization treatment time is 30s.

[0052] 3. Sterilization

[0053] Put the sealed red bean packaging bag into hot water for water bath sterilization, and obtain the red bean product after cooling, wherein the temperature of the hot water is 99° C., and...

Embodiment 2

[0058] 1. Cooking

[0059] Add red bean into water, heat, add edible white vinegar when the temperature rises to 98°C, mix with red bean and water, adjust the pH of the red bean aqueous solution to 4.59, keep the temperature at 98°C and cook for 30 minutes, then cool, wash and filter , to obtain boiled red beans, wherein the weight ratio of red beans and water is 100:650.

[0060] The hardness of the boiled red bean was adopted GWJ-1 type grain hardness meter, and the measurement results are shown in Table 1.

[0061] 2. Vacuum treatment

[0062] The boiled red bean is placed in a vacuum packaging bag, vacuumized, then sealed and packaged, wherein the absolute pressure during the vacuumization process is 0.5kPa, and the vacuumization time is 20s.

[0063] 3. Sterilization

[0064] Put the sealed red bean packaging bag into hot water for water bath sterilization, and obtain the red bean product after cooling, wherein the temperature of the hot water is 97° C., and the steril...

Embodiment 3

[0068] 1. Cooking

[0069] Add red bean into water, heat, add malic acid when the temperature rises to 90°C, mix with red bean and water, adjust the pH of the red bean aqueous solution to 4.0, keep the temperature at 90°C, cook for 50 minutes, cool, wash and filter to obtain The red bean is boiled, wherein the weight ratio of the red bean to water is 100:550.

[0070] The hardness of the boiled red bean was adopted GWJ-1 type grain hardness meter, and the measurement results are shown in Table 1.

[0071] 2. Vacuum treatment

[0072] The boiled red bean is placed in a vacuum packaging bag, vacuumized, then sealed, and packaged, wherein the absolute pressure during the vacuumization process is 1.0kPa, and the vacuumization treatment time is 30s.

[0073] 3. Sterilization

[0074] Put the sealed red bean packaging bag into hot water for water bath sterilization, and obtain the red bean product after cooling, wherein the temperature of the hot water is 97° C., and the steriliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com