Electrostatic multipole lens

A technology of electronic lens and electron column, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as difficulty in manufacturing, control and alignment, and influence on the resolution of electron columns, and achieve small electron beam spots and improve resolution , the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

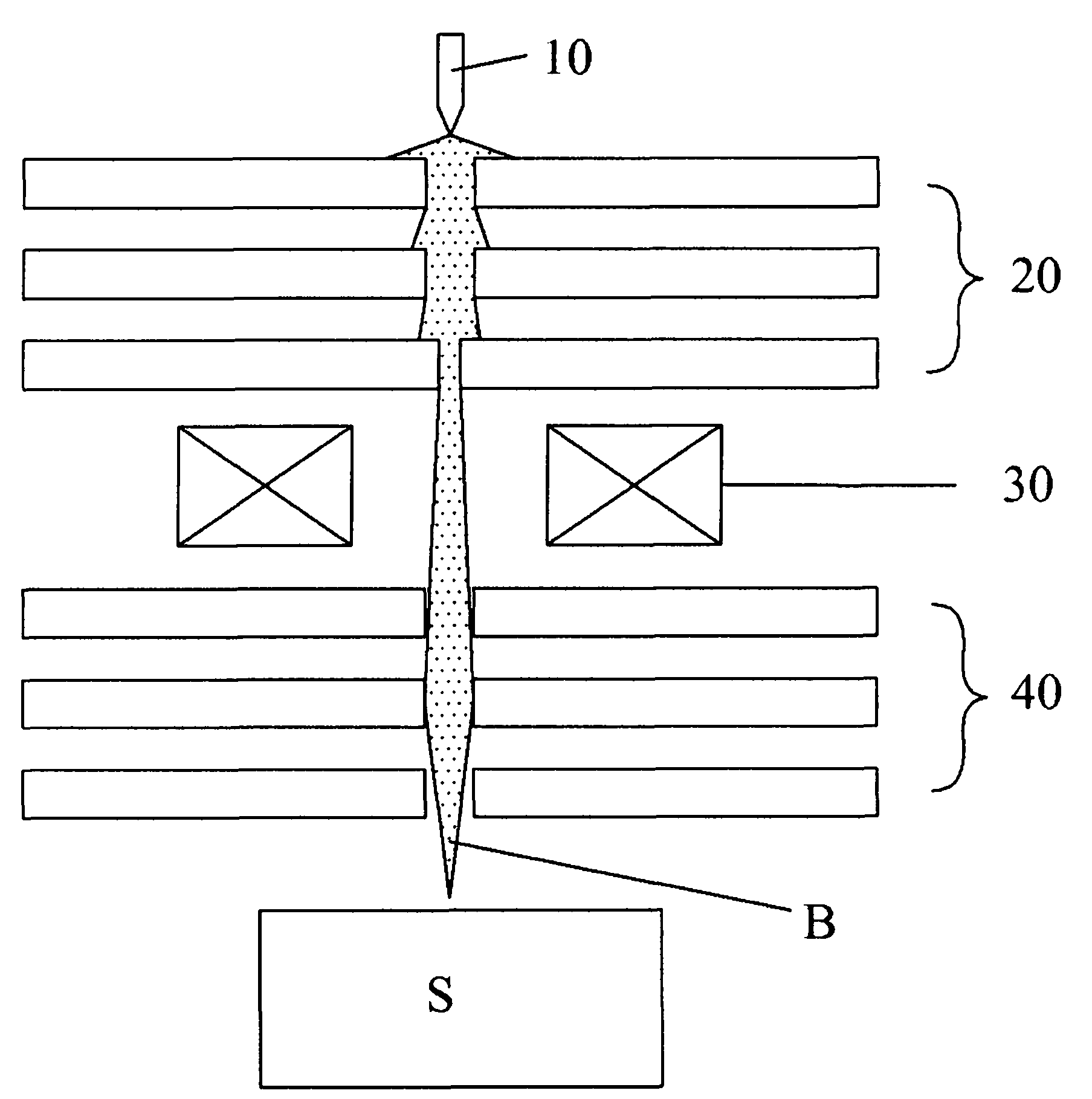

[0038] The present invention is provided for forming a low aberration, high resolution electron beam spot by using a multipole lens within an electron column.

[0039] The invention provides an electrostatic multipole lens, which can not only correct the astigmatism, but also correct the deformation of the beam spot of the whole deflection field, so as to improve the performance of the electron column.

[0040] The structure of the electrostatic multipole lens of the present invention is simple, and by using the multipole lens in the focusing lens, the beam spot of the electron beam generated by various types of distortion generated around the sample by the electron beam scanned by the electron column is reduced deflection defocus.

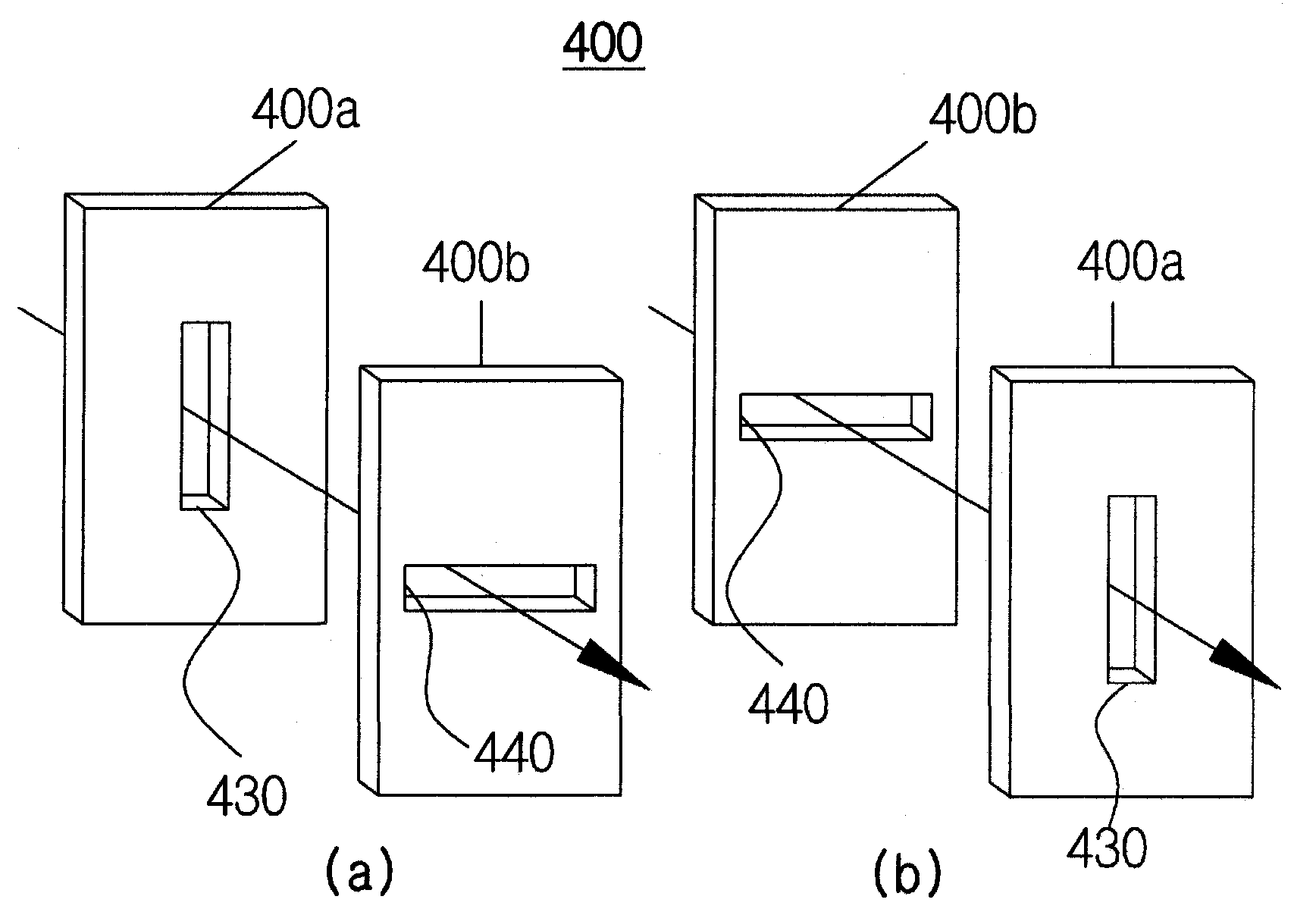

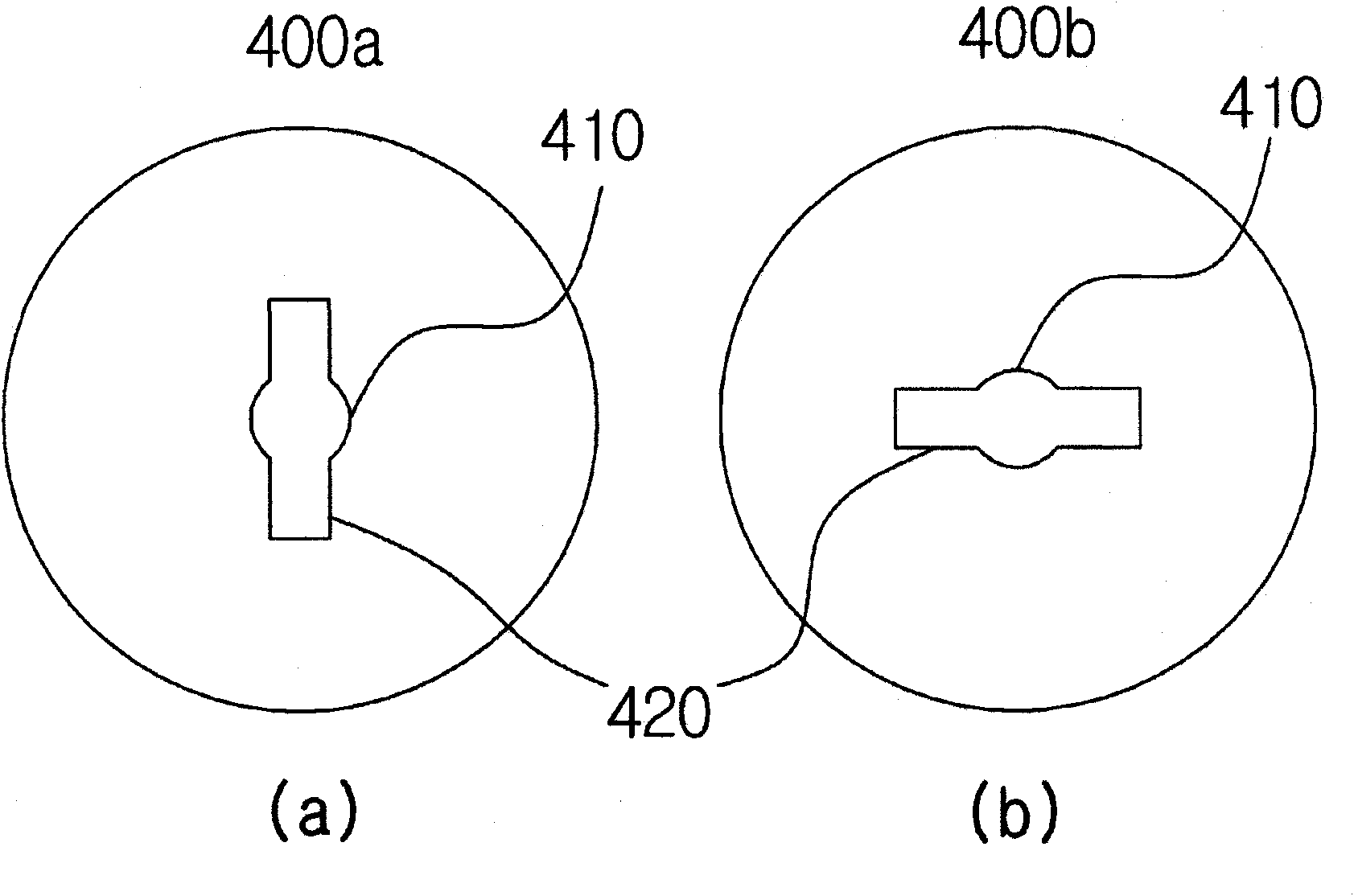

[0041] figure 2 One example of a multipole lens with a simple structure and orthogonal apertures is schematically shown.

[0042] exist figure 2 , each quadrupole lens 400 (i.e., a multipole lens for electro-optical design) is configured to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com