Method for assembling a socket for a discharge lamp and discharge lamp

A technology for discharge lamps and lamp caps, which is applied in the manufacture of discharge tubes/lamps, discharge lamps, high-pressure discharge lamps, etc., and can solve problems such as high cost of lamp caps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

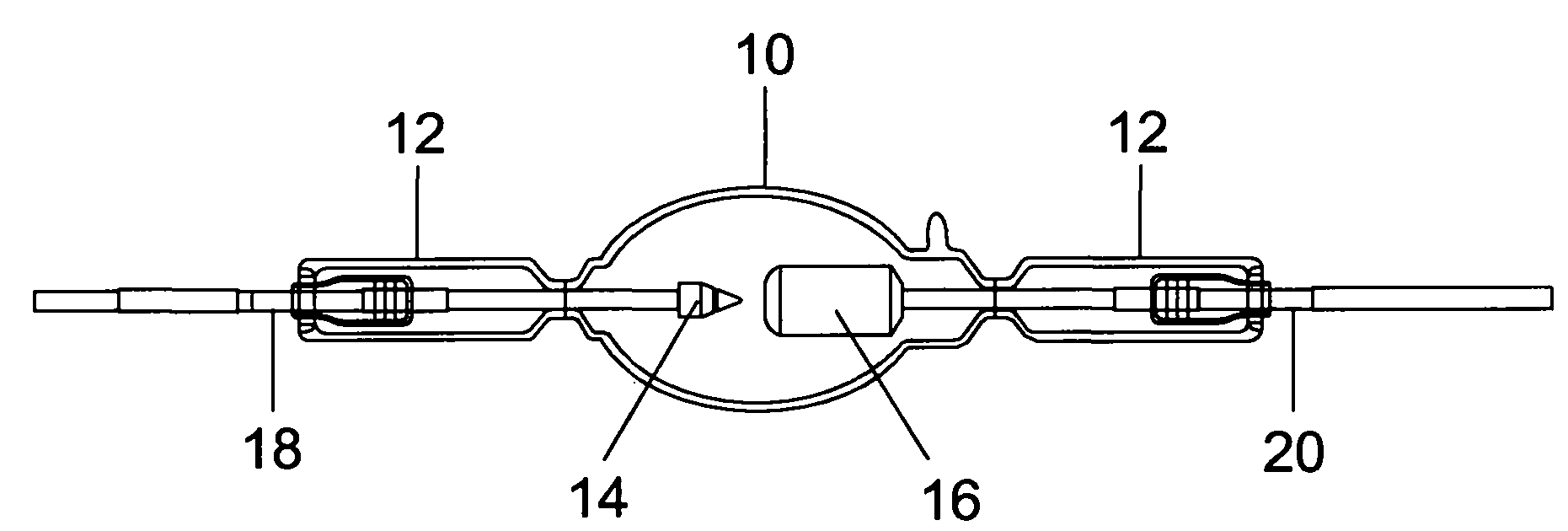

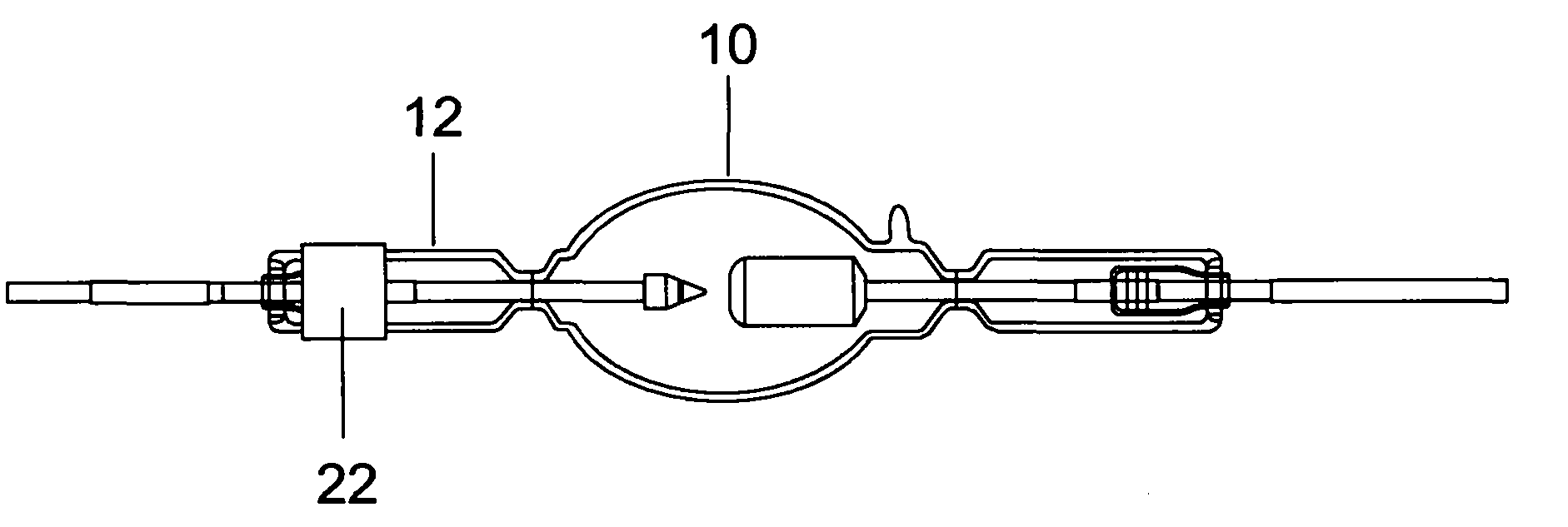

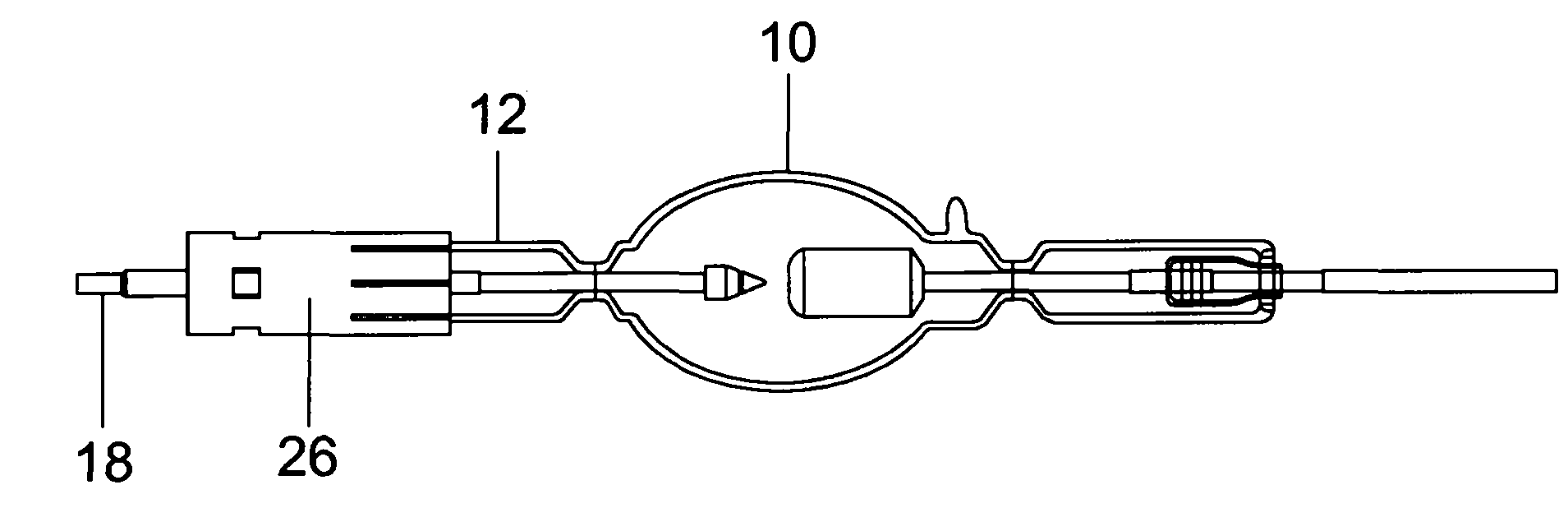

[0019] The method according to the invention is based on the Figure 1A High-pressure discharge lamp under manufacture in the state shown. After the discharge vessel 10 has been produced from glass or quartz glass with two cylindrical handles 12 connected on opposite sides, this state is obtained in the following manner by The electrode holding rods 18 and 20 are welded in each case in order to serve as an external connection for the electrodes, ie to provide contact possibilities with the electrodes. Electrode holding rods 18 and 20 protrude from the cylindrical shaft 12 , ie the two end regions of the discharge vessel 10 . A lamp cap will now be provided, by means of which the high-pressure discharge lamp can be inserted into a lampholder. Electrical contact with the electrode holding pin 18 or 20 will be established via the lamp cap. In the method described below, a single cap is applied to the discharge vessel 10 . Usually, a lamp cap is mounted on each of the two rod-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com