Giant magnetoresistance array current sensor

A technology of current sensor and giant magnetoresistance, which is applied in the field of smart sensors, can solve problems such as giant magnetoresistance output unipolarity, and achieve the effect of improving real-time performance and weakening magnetic field interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

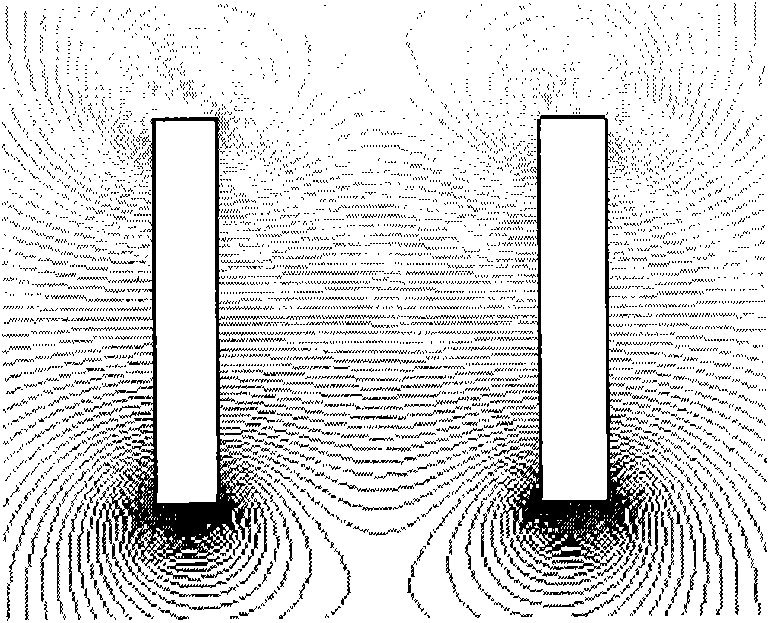

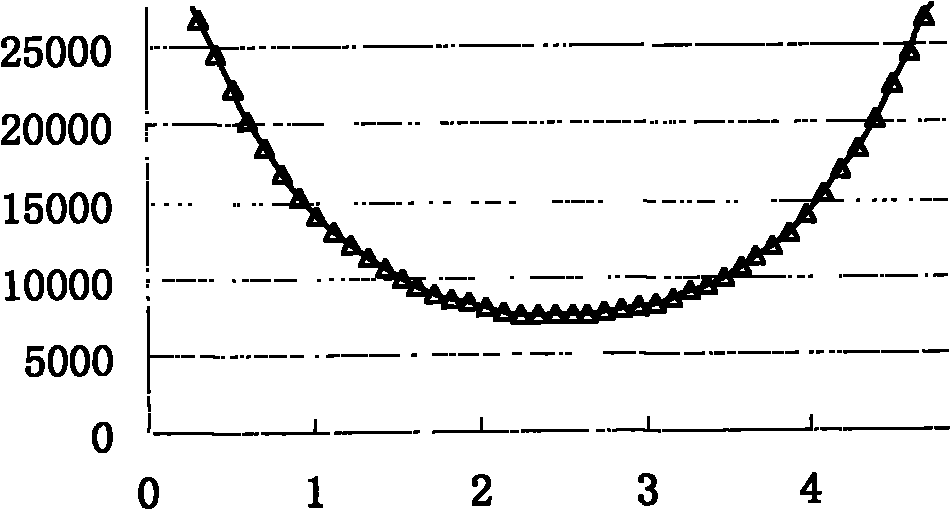

[0030] figure 1 It is a schematic structural block diagram of the present invention. Such as figure 1 As shown, the present invention includes: giant magnetoresistive chip sub-board array 1, annular PCB motherboard 2, 8-channel voltage amplifier circuit 3, 8-channel sampling and holding and A / D conversion circuit 4, and FPGA processing circuit 5. The GMR chip sub-board array 1 is composed of 8 GMR sub-boards. Each sub-board is composed of a giant magnetoresistance chip AA005-02 and two bar-shaped AlNiCo permanent magnets. The two bar-shaped permanent magnets are respectively placed at both ends of the giant magnetoresistance chip AA005-02. The direction is consistent with the magnetic sensitivity direction of giant magnetoresistive chip AA005-02. The 8 giant magnetoresistive sub-boards are evenly distributed on the ring-shaped PCB motherboard 2 with the same radius and equal angle. After the output voltage signal is amplified by the 8-channel voltage amplifier circuit 3, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com