High-accuracy micro-displacement detection device for deep hole internal diameter detection

A detection device and high-precision technology, applied in the field of instruments and meters, can solve the problems that the processing consistency of inductive displacement sensors cannot meet the measurement accuracy requirements, the measurement method of deep holes with male and female rifling is not suitable, and the probe wear of inductive displacement sensors, etc. Achieve the effects of small error, perfect function and intuitive reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

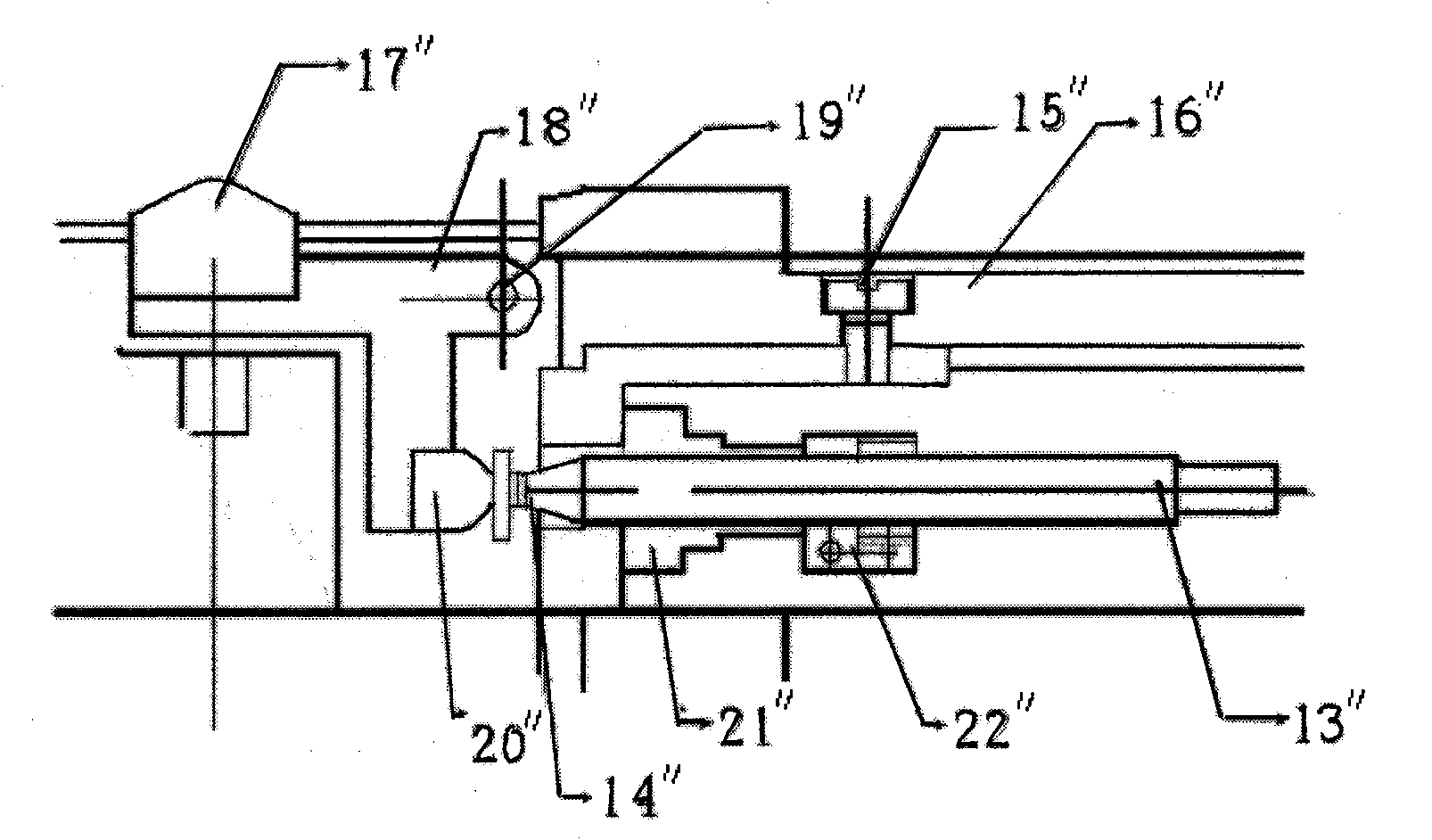

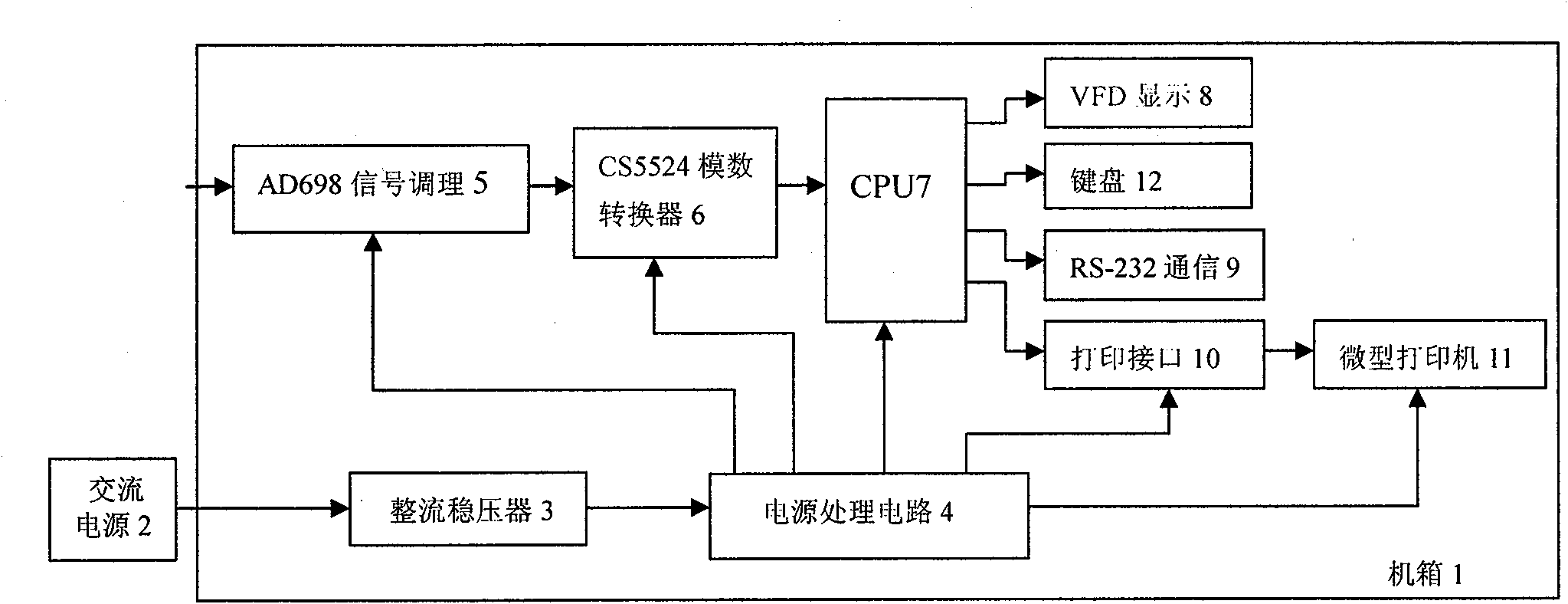

[0018] The present invention includes an electrical processing part and a mechanical processing part; the mechanical processing part includes: the measurement transmission mechanism includes: a sensor 13, a detection contact iron 14, a fixing bolt 15, a measuring bracket 16, an alloy probe 17, a turret 18, and a rotating shaft 19 , alloy contacts 20, sensor seat 21, sensor fastening clip 22, the measuring bracket 16 is provided with a turret 18, the turret 18 is fixedly mounted on the measuring bracket 16 by a rotating shaft 19, and the upper ends on both sides of the central axis of the turret 18 are symmetrical An alloy measuring head 17 is provided, and the alloy measuring head 17 senses the change of the measured aperture and transmits the displacement to the turret 18; the rotating shaft 19 provides a fulcrum for the turret 18; the lower ends of both sides of the central axis of the turret 18 are arranged symmetrically There are alloy contacts 20, alloy contacts 20, in dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com